Household garbage incineration device without combustion-supporting of conventional fuel

A technology of domestic waste incineration and conventional fuel, applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of high pollutant content, secondary pollution, waste of resources, etc., and achieve simple equipment structure and low pollutant content Low, low investment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

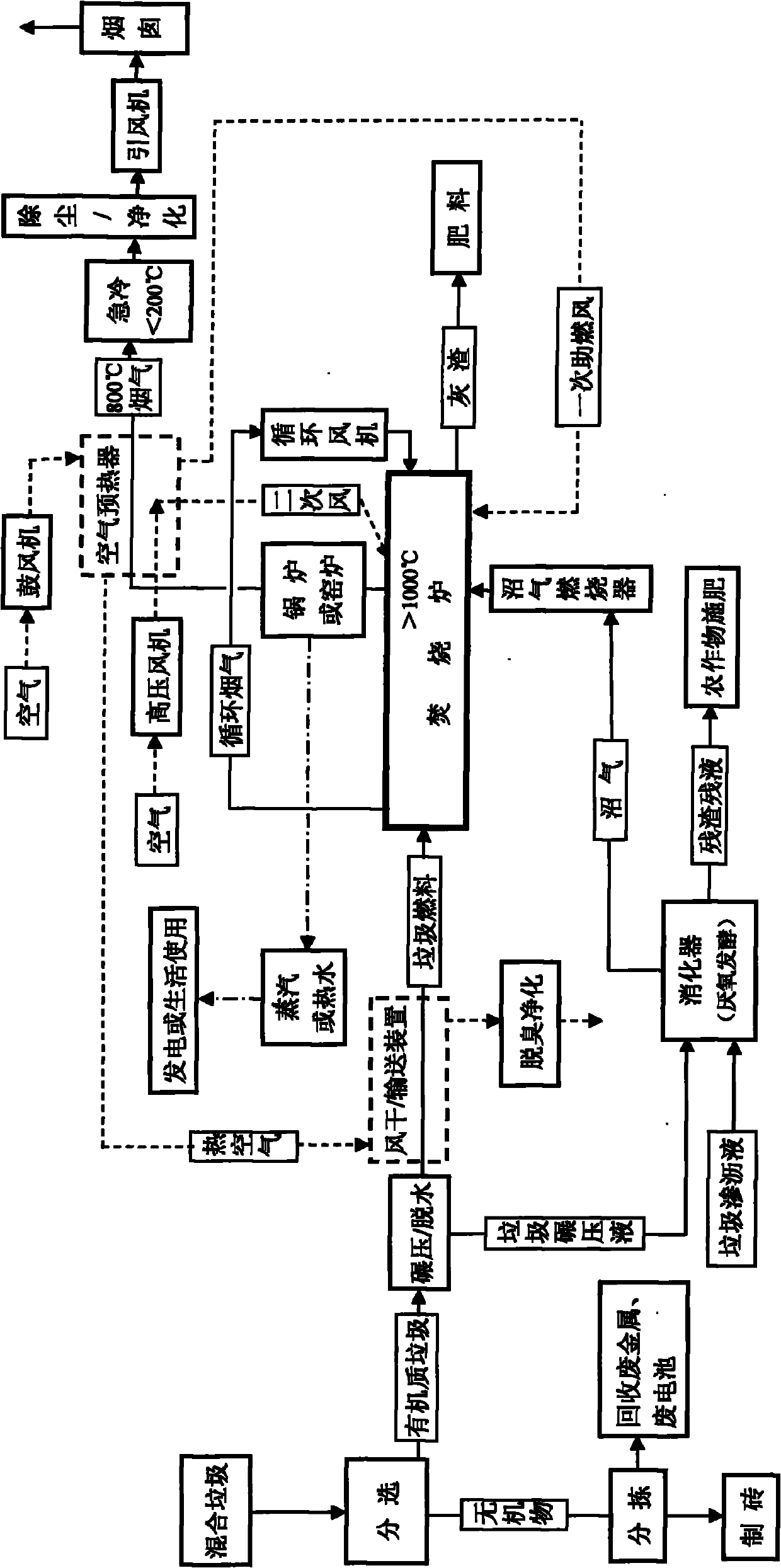

[0014] Example 1 figure 1 The conversion process of domestic waste incineration method shown mainly consists of waste sorting, rolling / dehydration, air drying / transportation, gasification / incineration, heat energy utilization, flue gas quenching, dust removal / purification, waste rolling liquid digestion and treatment, Inorganic brick making and other processes, among which the incinerator is a flue gas circulation incinerator. The mixed garbage mixed with inorganic substances such as masonry, mud and sand is mechanically sorted or manually sorted to select the organic garbage, and then the organic garbage is rolled and dehydrated, and the garbage rolling liquid and garbage generated during the rolling and dehydrating process are separated. The garbage leachate from the storage pit is sent to the digester to produce biogas by anaerobic fermentation. The biogas is used as auxiliary fuel for the incinerator, and the digested residue is used as fertilizer; the organic waste after ...

Embodiment 2

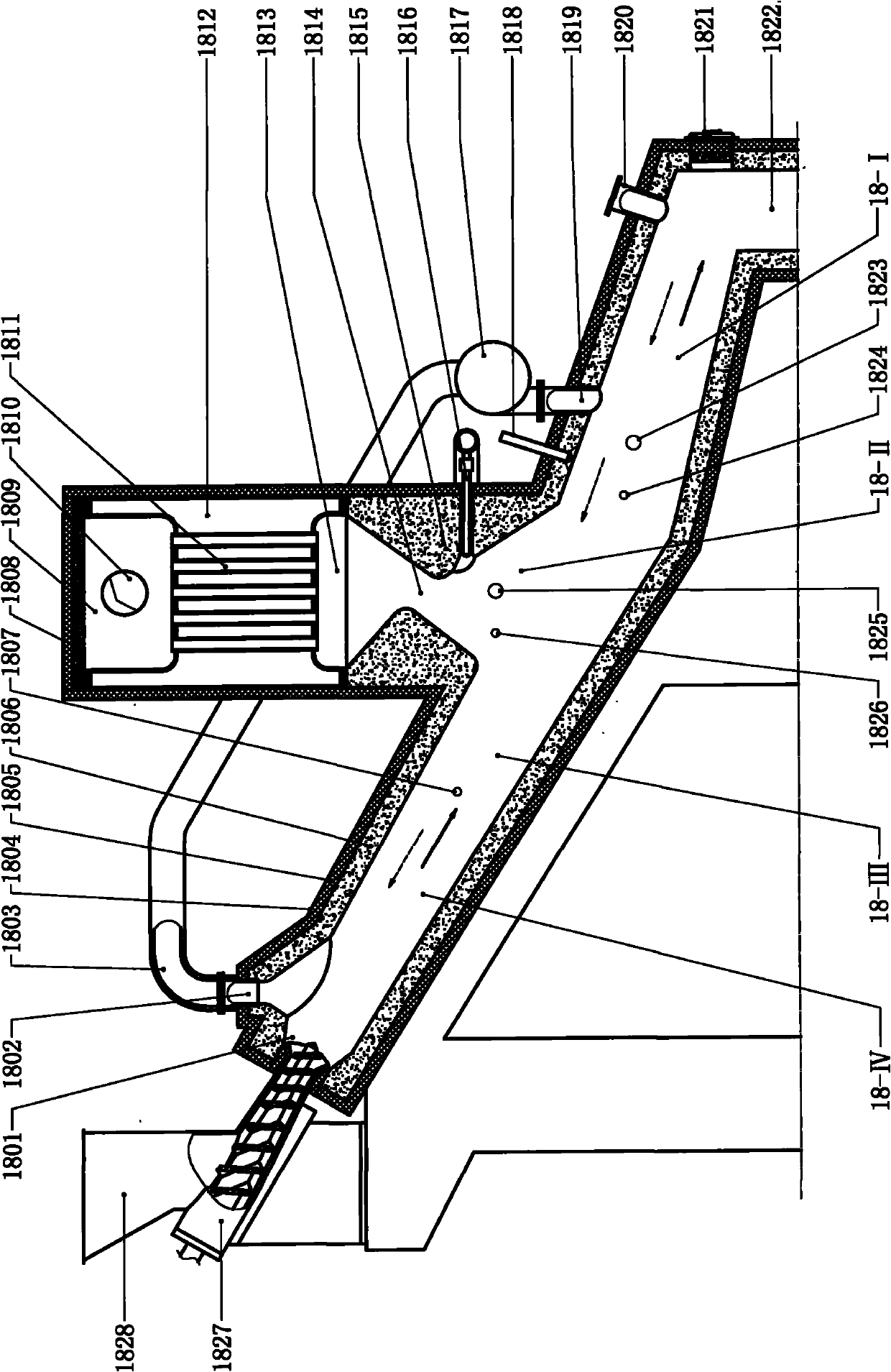

[0015] Embodiment 2 This embodiment is such as figure 2 As shown, the flue gas circulation incinerator is mainly composed of a furnace body, a flue gas circulation pipe (1803), a circulation fan (1817), a secondary air spray gun (1816), a biogas combustion spray gun (1818), a screw feeder (1827), Garbage hopper (1828) and boiler, wherein: the furnace body is composed of a revolving furnace wall, which is set with a high front and a low slope at the rear. The inner layer of the revolving furnace wall is a refractory layer (1806), and the middle layer is an insulating layer (1805) , the outer layer is a steel shell (1804); the furnace body is divided into a drying area (18-IV), a pyrolysis area (18-III), a gasification / combustion area (18-I) and a second The combustion zone (18-II), the drying zone (18-IV), the pyrolysis zone (18-III), the gasification / combustion zone (18-I) and the second combustion zone (18-II) are successively connected to each other , the drying zone (18-I...

Embodiment 3

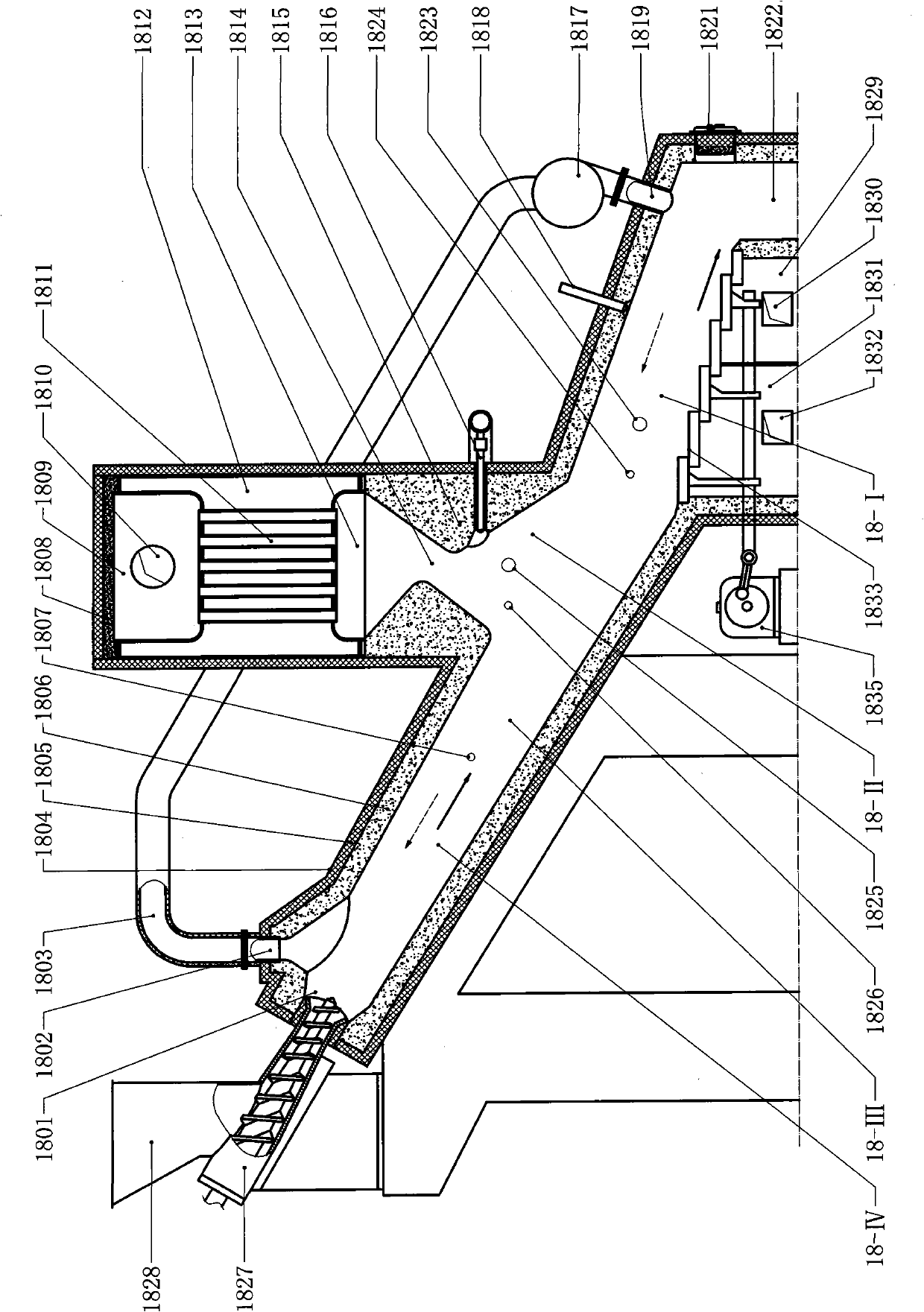

[0016] Embodiment 3 This embodiment is such as image 3 As shown, the difference between the flue gas circulation incinerator and the embodiment shown in Figure 6 is that there are a front air chamber (1831) and a rear air chamber (1829) below the gasification / combustion zone (18-I), and the gasification The chemical / combustion zone (18-I) is separated from the front air chamber (1831) and the rear air chamber (1829) by a reciprocating fire grate (1833), and the reciprocating fire grate (1833) is driven by the fire grate gearbox (1835) The primary combustion-supporting air enters the front air chamber (1831) and the rear air chamber (1829) from the front air door (1832) and the rear air door (1830) respectively, and then enters the gasification / combustion zone (18 through the ventilation holes of the fixed fire grate (1833) -I); the circulating flue gas input interface (1819) is connected from the top of the slag outlet (1822) at the tail of the incinerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com