Method for preparing biologic herbicide-containing fertilizer from biogas slurry

A technology of biological fertilizer and biogas slurry is applied in the field of comprehensive utilization of agricultural waste, which can solve the problems of narrow disease prevention range, low disease prevention effect, unstable application effect, etc., and achieves easy operation, good synergy and effect. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

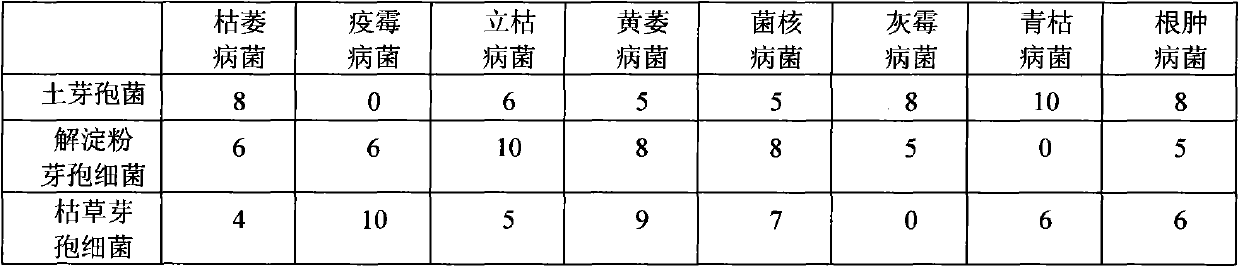

[0028] The acquisition and strain characteristics of three spore-forming bacterial strains:

[0029] The biogas slurry was obtained from the biogas project of Nanjing Shantian Dairy Farm. Collect 8-10 ml of biogas slurry in a 25 ml test tube, heat the test tube in a water bath at 80°C for 15 minutes, take it out and cool it to room temperature, and draw 200 microliters of biogas slurry into a 9 cm diameter petri dish under sterile conditions Then quickly add 20ml of PDA medium at 55-60°C, mix the two thoroughly and place it until the medium is completely solidified, then add 15ml of PDA medium at 55-60°C to the culture dish, gently horizontally After shaking well, place it horizontally, wait until the medium is completely solidified, evenly inoculate 5 pieces of mycelium with a diameter of 7 mm and fresh fungus of strawberry wilt on the medium, and place the culture dish at 28±2°C for 4 to 5 days. Use the inoculation loop to pick the colony that produces the inhibition zone 2...

Embodiment 2

[0034] Preparation of Three Bacillus Culture Medium

[0035] Preparation of test tube slant medium: Weigh 3 grams of beef extract, 10 grams of peptone, and 5 grams of sodium chloride, dissolve them in 1000 ml of water, adjust the pH to 7.4-7.6, add 15-20 grams of agar, heat and boil until the agar dissolves, Make up the volume to 1000ml, cool down properly and put it into test tubes, the filling volume is 1 / 5~1 / 6 of the test tube height, plug the test tube mouth with a test tube stopper, autoclave at 121°C for 25 minutes, take it out while it is hot, and put it on an inclined plane Until it is cooled for later use, the height of the inclined plane shall not exceed 1 / 3 of the height of the test tube.

[0036] Preparation of liquid seed medium: 3 grams of beef extract, 10 peptones, and 5 grams of sodium chloride, dissolved in 1000 ml of water, adjusted to pH 7.4 to 7.6, and then divided into 80 / 250 ml triangular flasks with cotton Stopper the mouth of the bottle, autoclave at 1...

Embodiment 3

[0040] Preparation of compound microbial agent

[0041] The preserved bacterial classification of three kinds of bacillus bacterium in embodiment 1 is inoculated respectively in the test tube slant medium and carries out the test tube slant surface activation, then, the bacterial classification activated is inoculated to the 250ml triangle that 80ml liquid seed medium is housed with the inoculating loop In the bottle, the Erlenmeyer flask was placed in a shaker for 24 hours, the rotating speed of the shaker was 160r / min, and the culture temperature was 28±2°C; after the end, insert the 800ml liquid production culture with 5% inoculum size (V / V). In a 2000ml Erlenmeyer flask, place the Erlenmeyer flask on a shaking table for cultivation, the rotating speed of the shaking table is 160r / min, and the cultivation temperature is 28±2°C. After 3 to 4 days of cultivation, the microscopic inspection of the spore formation rate is above 95%. Finish the cultivation; spray the liquid cult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com