Process for preparing yttrium aluminum garnet-based continuous fibers through sol-gel method

A garnet-based, continuous fiber technology, applied in fiber chemical characteristics, dry spinning, wet spinning, etc., can solve the problems of short length of yttrium aluminum garnet fiber, decreased fiber performance, easy growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

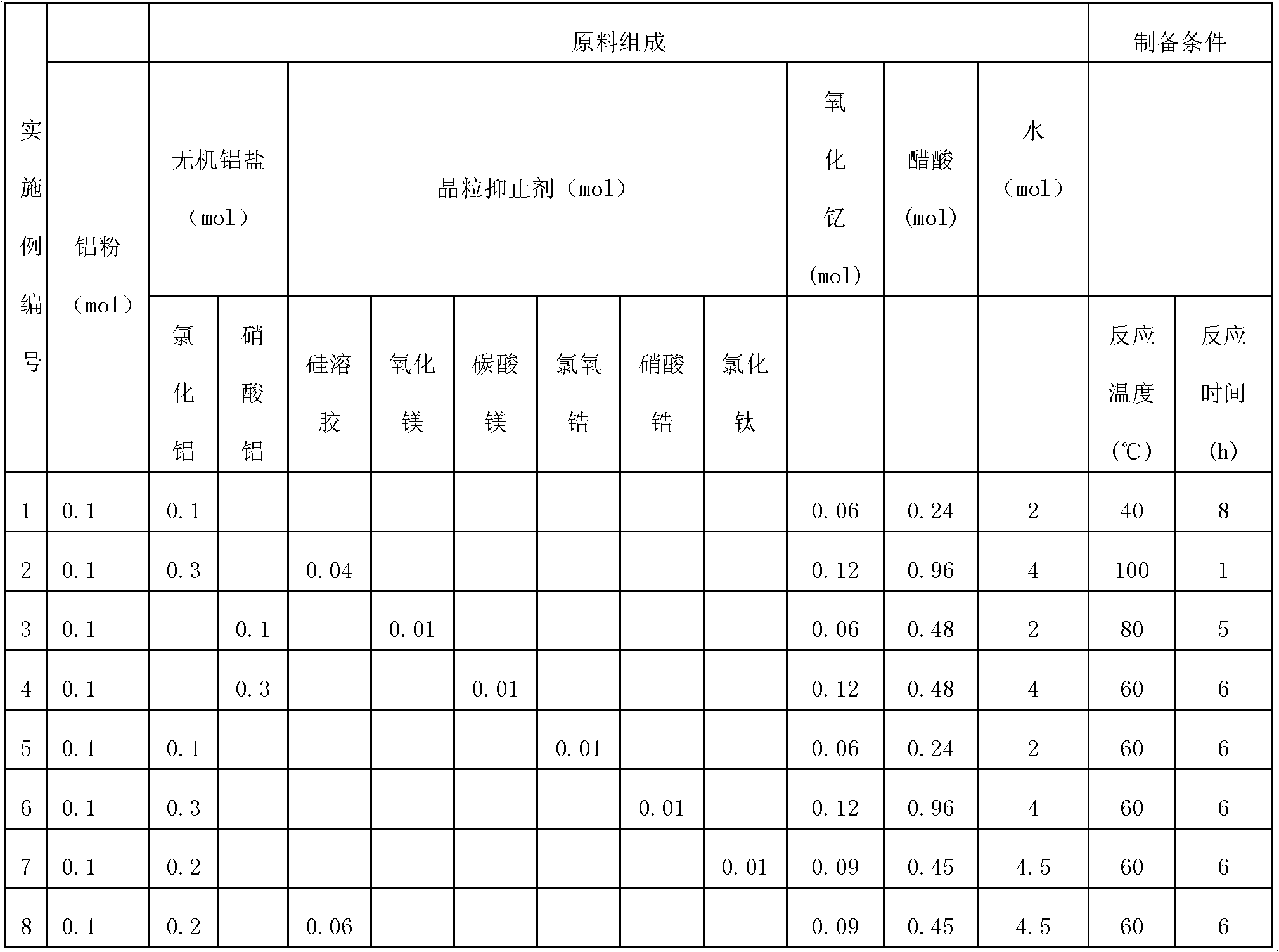

[0027] Table 1. Preparation of aluminum carboxylate precursor sol

[0028]

[0029] Note: the addition amount of silica sol in the embodiment is according to its SiO 2 Content calculation; the aluminum in the sol is the sum of the aluminum contained in the aluminum powder and the aluminum salt.

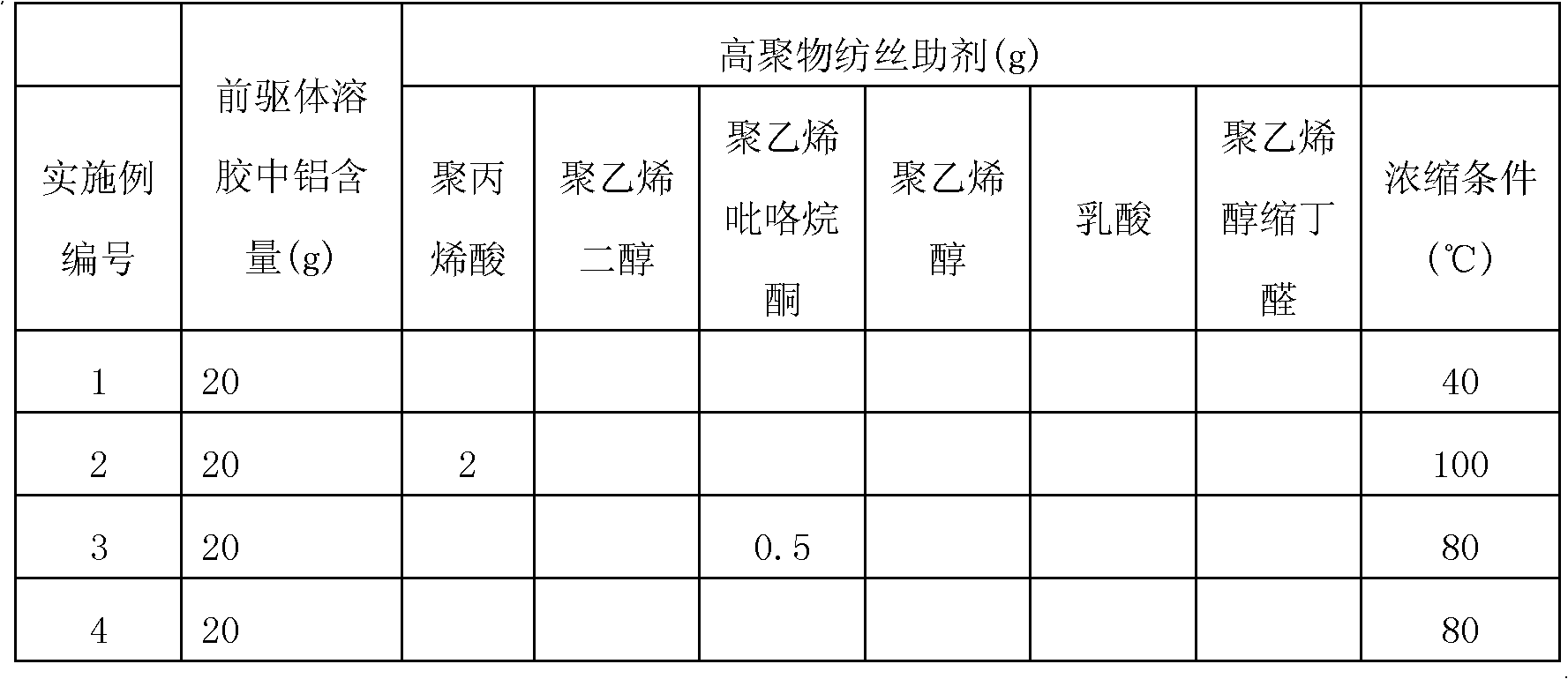

[0030] Table 2. Preparation of yttrium aluminum garnet-based fiber sol

[0031]

[0032]

[0033] Note: The aluminum in the sol is the sum of aluminum contained in aluminum powder and aluminum salt.

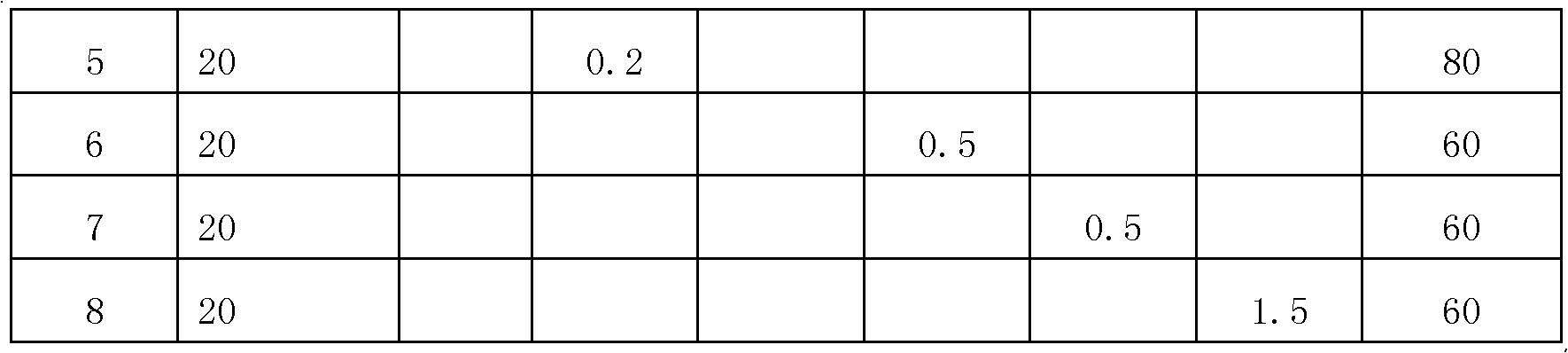

[0034] Table 3. Fiber drying and sintering process

[0035]

[0036] Table 4. Properties of yttrium aluminum garnet based fibers

[0037] Diameter (μm) Tensile strength (MPa) Maximum service temperature (°C)

Embodiment 1

[0038] Example 1 20-40 730±10 1300

Embodiment 2

[0039] Example 2 10-30 620±10 1200

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com