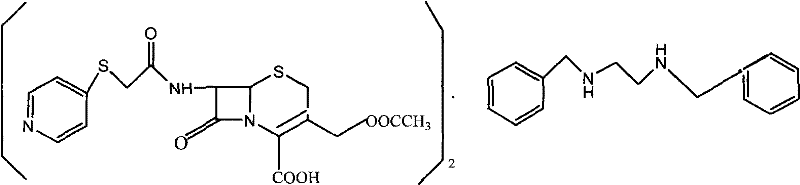

Method for preparing cephapirin benzathine

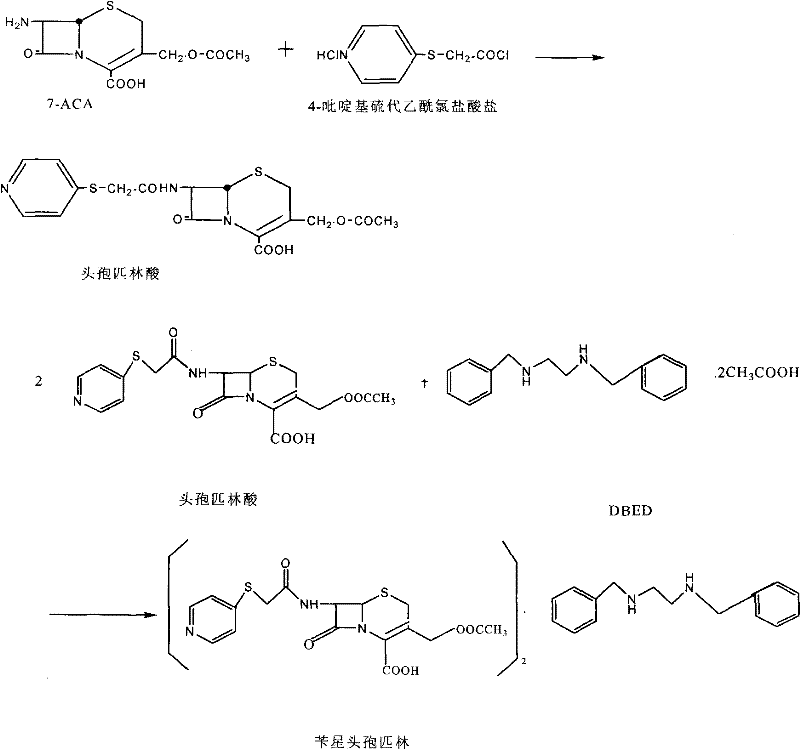

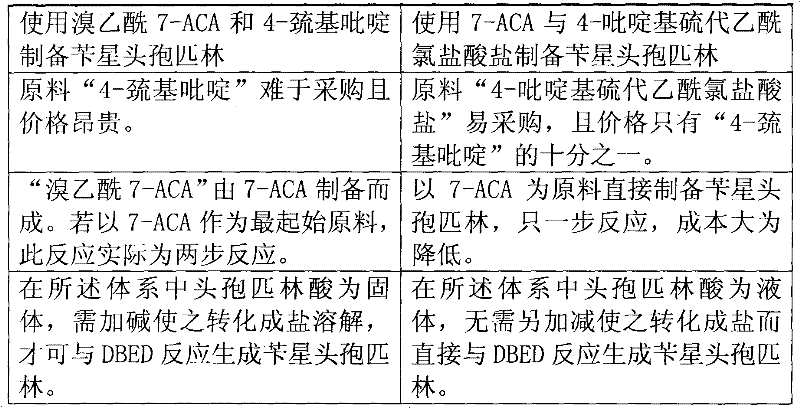

A technology of benzathine cefapirin and a manufacturing method is applied in the field of cephalosporin chemical drug synthesis, and achieves the effects of easy availability of raw materials, less production process flow, and simple production process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 100 grams of 7-ACA into a mixed solvent of 2500 milliliters of acetone and 250 milliliters of water, cool down to 0-5° C., add 190 milliliters of triethylamine to dissolve the solid, pH=8-9. Add 200 grams of 4-pyridylthioacetyl chloride hydrochloride and react at 10° C. for 3 hours. After the reaction is complete, add 8 grams of activated carbon for decolorization and filter. Add 1,500 milliliters of water, add 100 grams of DBED at room temperature, react at 37 to 40° C. for 6 hours, filter, wash the product with 3×300 milliliters of water, and dry in vacuo to obtain white solid cefepirin benzathine. Molar yield is 94~97%, adopts Agilent 1200 liquid chromatographs to measure and contain cefapirin acid 79% (USP31 standard is 71.5~82.0%), adopts titration method to measure and contain benzathine 22% (USP31 standard is 20.0%) ~24.0%).

Embodiment 2

[0026] 100 grams of 7-ACA was added to a mixed solvent of 2500 milliliters of acetone and 100 milliliters of water, the temperature was lowered to 0-5 ° C, and 190 milliliters of triethylamine was added to dissolve the solid. Add 200 grams of 4-pyridylthioacetyl chloride hydrochloride and react at 10° C. for 3 hours. After the reaction is complete, add 8 grams of activated carbon for decolorization and filter. Add 1,500 milliliters of water, add 100 grams of DBED at room temperature, react at 37 to 40° C. for 6 hours, filter, wash the product with 3×300 milliliters of water, and dry in vacuo to obtain white solid cefepirin benzathine. The molar yield was 86%.

Embodiment 3

[0028] 100 grams of 7-ACA was added to a mixed solvent of 1000 milliliters of acetone and 250 milliliters of water, the temperature was lowered to 0-5° C., and 190 milliliters of triethylamine was added to dissolve the solid. Add 200 grams of 4-pyridylthioacetyl chloride hydrochloride and react at 10° C. for 3 hours. After the reaction is complete, add 8 grams of activated carbon for decolorization and filter. Add 1,500 milliliters of water, add 100 grams of DBED at room temperature, react at 37 to 40° C. for 6 hours, filter, wash the product with 3×300 milliliters of water, and dry in vacuo to obtain white solid cefepirin benzathine. The molar yield was 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com