Nano modified polyethylene flexible packing material

A low-density polyethylene and ethylene technology, applied in the field of nano-modified polyethylene flexible packaging materials, can solve the problems of poor heat resistance, increased LDPE thickness, high scrap rate, etc., and achieve the effect of low price and good printing suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

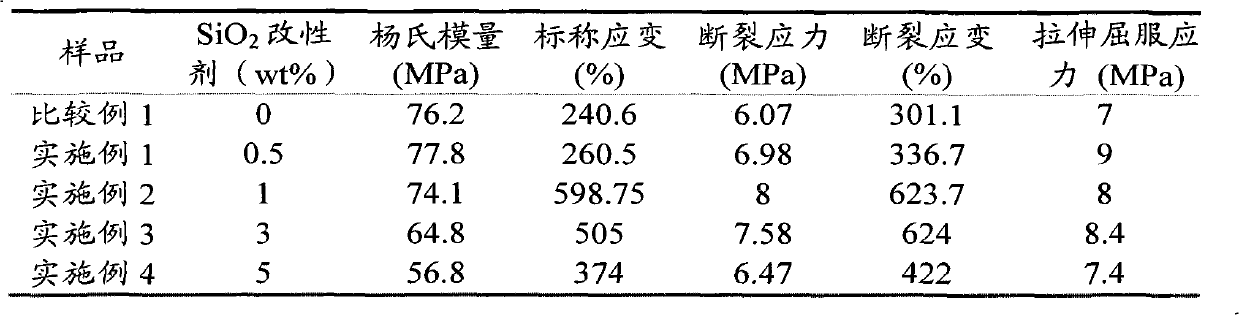

Examples

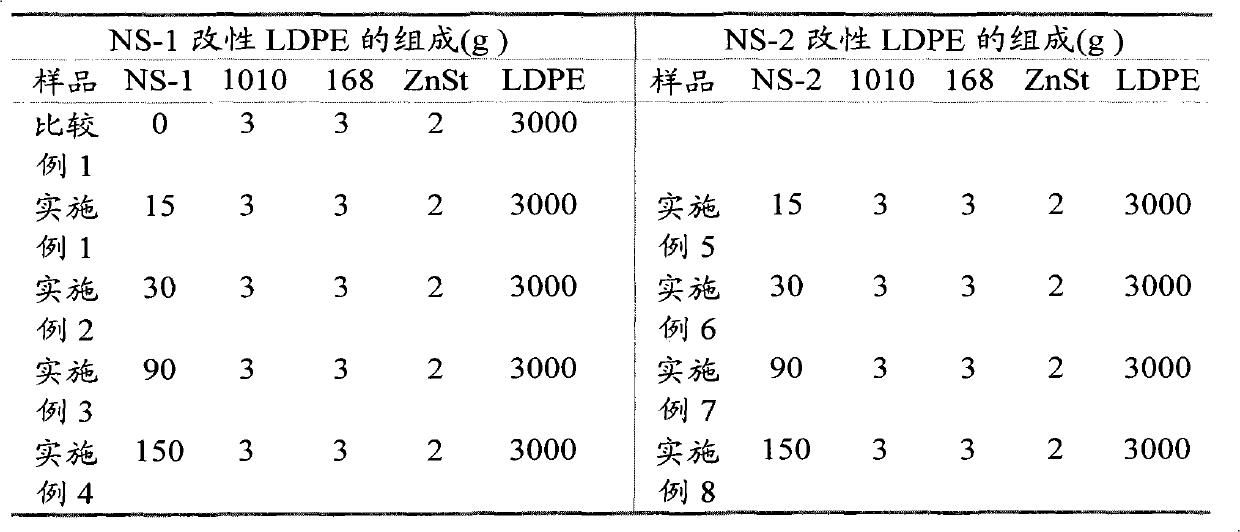

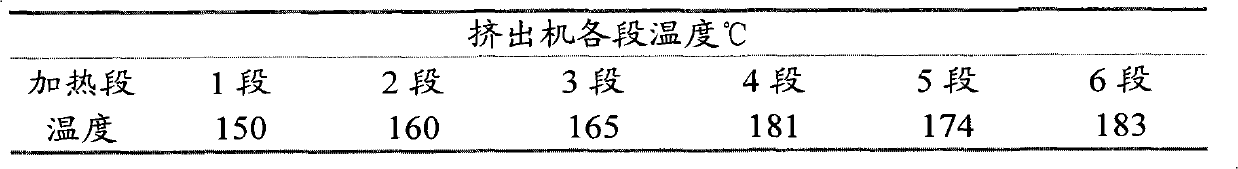

Embodiment 1~8

[0083] 1.1 Preparation of experimental materials:

[0084] The processing aid composition of polyolefin for food packaging containing nano-silica, which may be referred to herein as "nano-silica", "nano-modifier", "nano-processing aid", "nano-aid", "Nano-auxiliary composition" or "nano-processing aid composition", etc., have the same meaning. The following tests are carried out with the nano-silica processing aid composition of NS-1 or NS-2 as an example. Illustrate, prepare nano silicon dioxide as follows.

[0085] 1.1.1 Preparation of nano-silica (model NS-1):

[0086]Adding 120 grams of EVA emulsion with a solid content of 50% in a 500-milliliter four-necked bottle equipped with an electric stirrer, a thermometer, and a dropping funnel, the temperature of the system is controlled at 40° C. In 30 minutes, drop 15 grams of water glass (40 ° Be, modulus 3.5) into the above system from the dropping funnel, and mix for 1 hour. Add 10% (v%) sulfuric acid aqueous solution dropw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com