Coordination compound for catalyzing vinyl polymerization and preparation method of coordination compound as well as catalyst containing coordination compound and application of catalyst

A technology for catalyzing ethylene and complexes, applied in the direction of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, hydrocarbons, etc., can solve the problems of few researches and low catalytic activity, and achieve molecular weight Effects of narrow distribution, high catalytic activity, broad industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

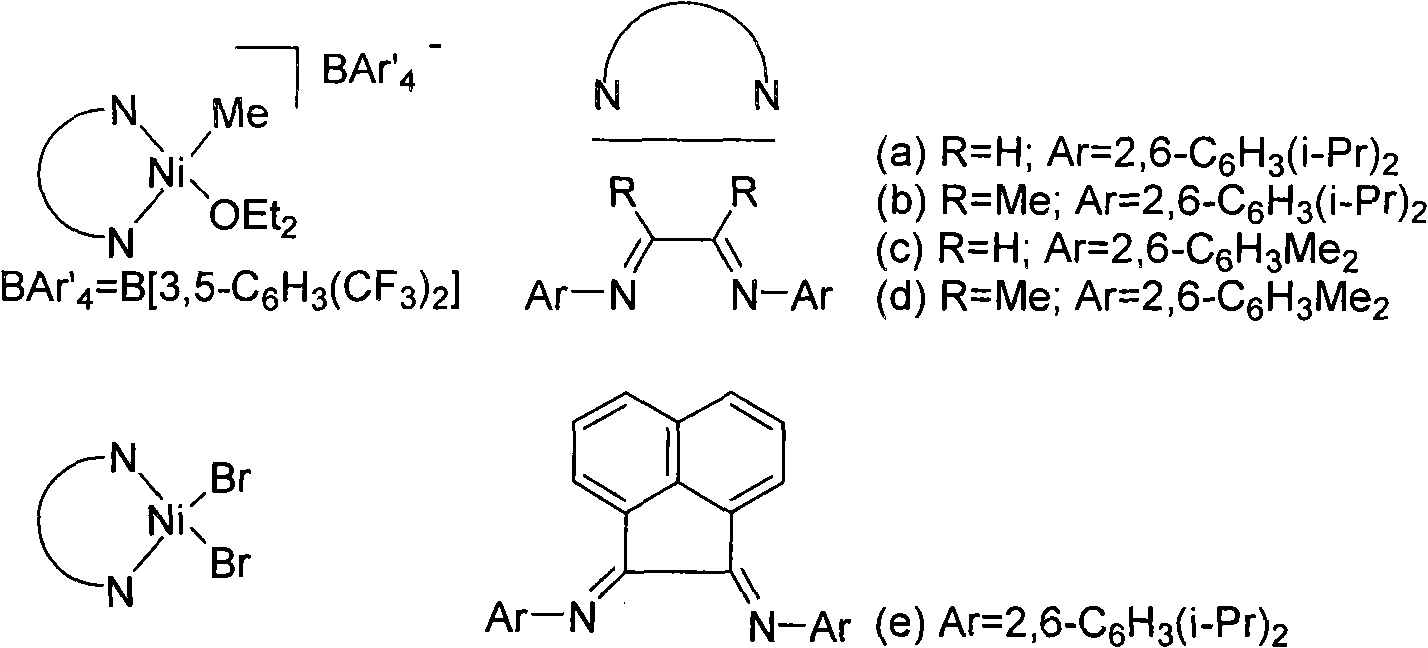

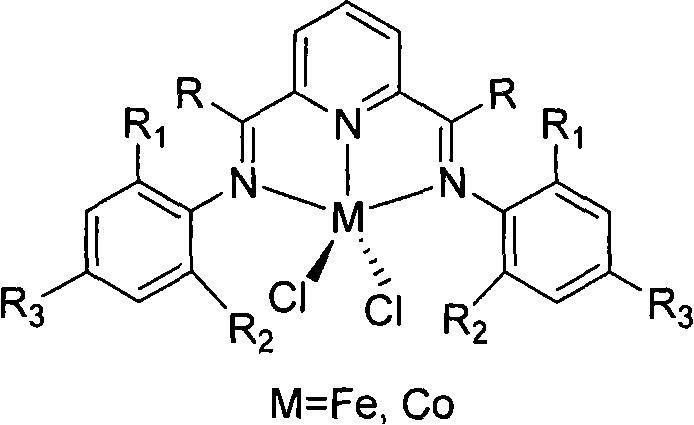

Method used

Image

Examples

Embodiment 1

[0025] 1. Synthesis of ligand 8-benzimidazole quinoline: quinoline-8-carboxylic acid (1.73g, 10mmol), o-phenylenediamine (1.08g, 10mmol) and polyphosphoric acid 8g were mixed together; microwave irradiation 1min, Cool, and repeat this 3 times; to obtain a dark green liquid, pour it into ice water while it is hot, neutralize it with ammonia water until the pH value is 8-9, and filter. After the filter cake was dried, it was separated by column chromatography (silica gel carrier, ethyl acetate / petroleum ether=1 / 1) to obtain 1.467 g of a white solid with a yield of 60%.

[0026] 2. Preparation of [8-benzimidazolinoline]iron(II) chloride [complex 1]: 8-benzimidazolinoline ligand (0.049g, 0.2mmol) and FeCl 2 4H 2 O (0.040g, 0.2mmol) was placed in a Schlenk tube, vacuumized and filled with nitrogen three times, then 4ml of degassed tetrahydrofuran was added, the reaction solution first formed an orange precipitate from an orange solution, stirred and reacted at room temperature for...

Embodiment 2

[0029] 1. Synthesis of ligand 8-(N-methylbenzimidazole) quinoline: 8-benzimidazole quinoline (1.47g, 6mmol) was dissolved in 20mL of acetone, and sodium hydroxide (0.504g, 9mmol) was added to In this solution, after stirring at room temperature for 3h, iodomethane (1.022g, 7.2mmol) was added, stirred at room temperature for 6h, the solvent was removed under reduced pressure, and column chromatography (silica gel carrier, ethyl acetate / petroleum ether=1 / 1) gave white Solid 1.39 g, 89% yield.

[0030]2. Preparation of [8-(N-methylbenzimidazole) quinoline]iron(II) [complex 2] chloride: the preparation method is the same as in Example 1, and the 8-benzimidazole in Example 1 Quinoline was replaced by 8-(N-methylbenzimidazole)quinoline, and the yield was 87%.

[0031] 3. Ethylene polymerization: Compound 2 (2μmol), toluene (40mL) and methylalumoxane (6mmol) were added into a 100mL reaction kettle in a glove box, and then the kettle was sealed and taken out of the glove box. Heat t...

Embodiment 3

[0033] 1. Synthesis of ligand 8-(N-ethylbenzimidazole) quinoline: the synthetic method is the same as that of the ligand in Example 2, except that methyl iodide is replaced with ethyl iodide, and the yield is 77%.

[0034] 2. Preparation of [8-(N-ethylbenzimidazole) quinoline]iron(II) [complex 3] chloride: the preparation method is the same as in Example 1, and the 8-benzimidazole in Example 1 Quinoline was replaced by 8-(N-ethylbenzimidazole) quinoline, and the yield was 75%.

[0035] 3. Ethylene polymerization: Compound 3 (2μmol), toluene (40mL) and methylalumoxane (6mmol) were added into a 100mL reaction kettle in a glove box, and then the kettle was sealed and taken out of the glove box. Heat to 100°C, pressurize to 30atm, stir under this condition for 30min, then stop the reaction, the ethylene gas will be evacuated, cool to room temperature, the reaction mixture is washed with 5% hydrochloric acid ethanol solution, filtered, and dried Obtain polyethylene 3.47g, activity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com