Method for synthesizing tributyl citrate

A technology of tributyl citrate and synthesis process, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as equipment corrosion, complicated post-treatment, and pollute the environment, and achieve mild reaction conditions. , The effect of small amount of catalyst and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

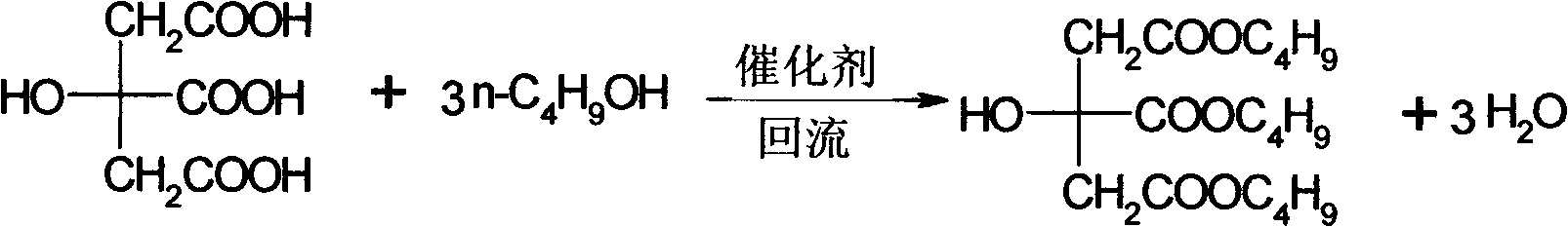

Image

Examples

Embodiment 1

[0027] Embodiment 1, the preparation of tributyl citrate

[0028] (1) Gelatinized starch-based carbon-based solid acid: Add 10g of starch into 50ml of water, heat and stir at 70°C for 4 hours to obtain starch sol, place it in an oven at 85°C for drying, and finally add 5g of isethionic acid for After stirring and mixing, place it in a quartz tube muffle furnace, replace the air with nitrogen, and heat to 200°C in a nitrogen atmosphere for carbonization reaction for 12 hours to obtain a black solid. After the solid is cooled to room temperature, add 80°C The above hot water is washed and filtered until the filtrate is clear and acidic, and then the solid is placed in an oven at 120°C for 1 day to obtain an acid value of 2.3mmol / g and a thermal decomposition temperature of 2.3mmol / g. 180°C;

[0029] (2) Esterification reaction: Add 0.1mol citric acid and 0.45mol n-butanol to a 100mL three-necked bottle equipped with electromagnetic stirring, a thermometer, a reflux condenser, a...

Embodiment 2-4

[0032] The preparation method is the same as in Example 1, except that the amount of gelatinous starch-based carbon-based solid acid is 0.3 g, the amount of citric acid is 0.1 mol, the amount of n-butanol is according to the ratio in Table 1, and the reaction is 4 hours.

[0033] Table 1. Productivity comparison under different acid-alcohol ratios

[0034] Example

Embodiment 5-7

[0036] The preparation method is the same as that in Example 1, except that the gelatinous starch-based carbon-based solid acid is used in the amounts shown in Table 2.

[0037] Table 2, the yield contrast under different gelatinous starch-based carbon-based solid acid dosages

[0038] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com