Catalyst for producing low-cloud-point lube base oil and preparation method thereof

A lubricating oil base oil and catalyst technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high base oil cloud point, low conversion ability, and limited ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

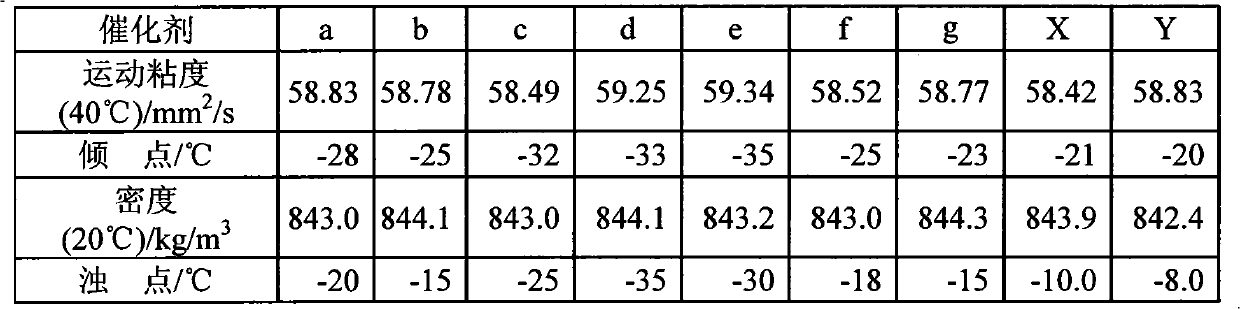

Examples

Embodiment 1

[0016] Based on the total weight of the mixed substance before crystallization, 5% pseudo-boehmite, 15% phosphoric acid, 5% di-n-propylamine, 10% silica sol (SiO 2 The content is 40% by weight) and the balance of water are mixed evenly and then transferred to a synthesis kettle for crystallization at 200 ° C for 24 hours, washed to neutral, dried until no clear water appears, and AEL molecular sieves are obtained. Then account for 0.5% sodium metaaluminate, 20% sodium metasilicate, 4% cetyltrimethylammonium bromide, 10% synthetic AEL type microporous molecular sieve and the balance After mixing the water evenly, use 1.0mol / L ammonia solution to adjust the pH value to 9.0, transfer it to a synthesis kettle for crystallization at 140°C for 48 hours, wash until the solution is neutral, dry until no clear water appears, and roast at 500°C for 6 Hours later, the AEL-MCM composite molecular sieve with the mesoporous template removed was obtained. The composite molecular sieve was i...

Embodiment 2

[0018] Based on the total weight of the mixed substance before crystallization, 10% pseudo-boehmite, 20% phosphoric acid, 10% diisopropylamine, 1% silica sol (SiO 2 The content is 40% by weight) and the balance of water are mixed evenly, then transferred to a closed synthesis kettle, crystallized at 160°C for 96 hours, washed to neutral, and dried until no clear water appears to obtain AEL type molecular sieve. Then account for 15.0% sodium metasilicate, 2.0% aluminum nitrate, 3.0% cetyltrimethylammonium chloride, 0.5% synthetic AEL type microporous molecular sieve and the water of the remainder After mixing evenly, adjust the pH value to 11.0 with 1.0 mol / L hydrochloric acid, transfer to a closed synthesis kettle and crystallize at 100°C for 96 hours to obtain a composite molecular sieve. Dry the composite molecular sieve until no clear water appears, and after calcination at 700°C for 4 hours, exchange it with 1.0 mol / L ammonium carbonate aqueous solution for 6 hours to obta...

Embodiment 3

[0020] Based on the total weight of the mixed substance before crystallization, mix 8% of pseudoboehmite, 17% of phosphoric acid, 15% of di-n-propylamine, 3% of silica sol and the rest of the water and then transfer to an airtight The synthetic kettle was crystallized at 200°C for 48 hours, washed to neutrality, and dried until no clear water appeared to obtain AEL molecular sieve. Then account for 1% sodium metaaluminate, 10% silica sol (SiO 2 Content is 40% by weight), 5% cetyltrimethylammonium bromide, 4% synthetic AEL type microporous molecular sieves and the water of the remainder mix uniformly with 1.0mol / L ammonia solution to adjust the pH of the solution The value was 10.0, and transferred to a closed synthesis kettle for crystallization at 140°C for 48 hours. The composite molecular sieve was dried until no clear water appeared, and after calcination at 600°C for 5 hours, it was exchanged with 1.0mol / L ammonium carbonate aqueous solution for 5 hours to obtain a BET s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com