Method for extracting and separating statins substance

A statin and substance technology, applied in the field of using supercritical CO2 extraction technology to extract and separate statin substances, can solve the problems of organic solvent residue, high production cost, affecting the quality of finished products, etc., to prevent the existence of human harmful substances and prevent oxidation And the effect of escape, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Supercritical CO 2 Selection of process parameters in extraction

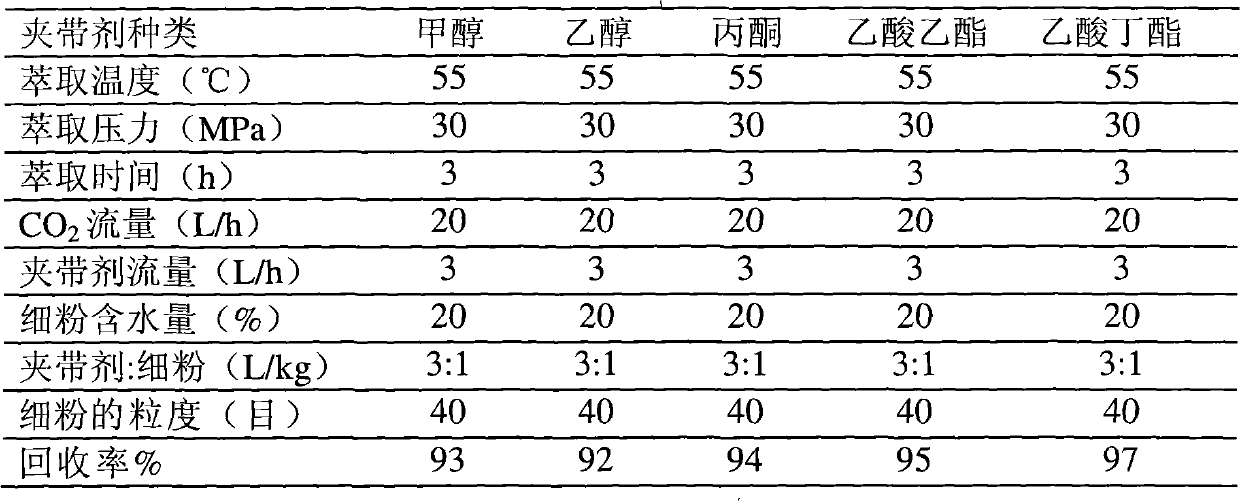

[0041] In the method of the present invention, the separation step, the type of entrainer, extraction temperature, extraction pressure, extraction time, CO 2 The flow rate, the volume-to-weight ratio of entrainer to mycelial powder all have important effects on the recovery rate. In the present invention, the inventors have done a lot of creative research work to select the above parameters.

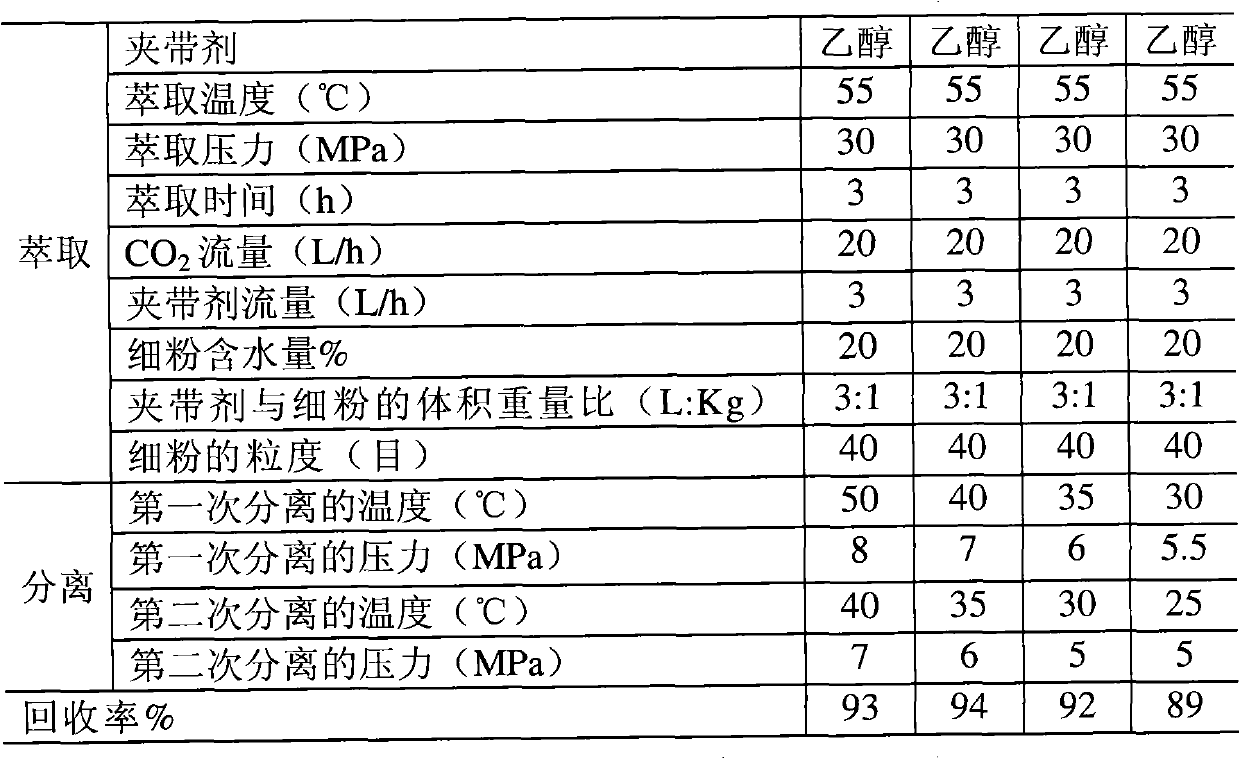

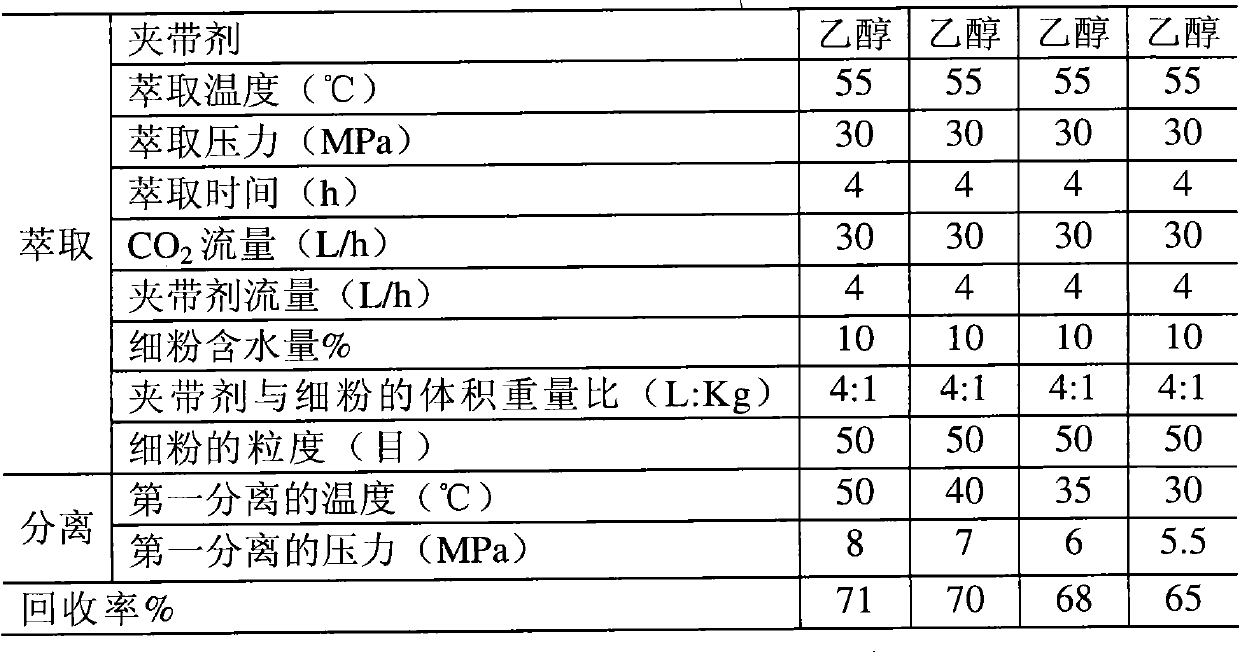

[0042] 1. Selection of separation step conditions

[0043] in supercritical CO 2 The separation step after extraction can adopt a primary separation process or a secondary separation process, wherein the conditions of the separation step have an important impact on the recovery rate. The conditions in the process of secondary separation are investigated below, and the investigation process is as follows:

[0044] Method: The mycelia obtained after fermentation of Penicillium citrinum HD-32-2 (i.e. th...

Embodiment 2

[0111] With the mycelia obtained after the fermentation of Penicillium citrinum HD-32-2 (i.e. the crude product of mevastatin, purchased from Chongqing Industrial Microbiology Pharmaceutical Engineering Technology Research Center) as raw material, its water content was determined to be 20%, and it was pulverized into 40 mesh fine powder. Put the above fine powder into supercritical CO 2 In the extraction kettle, adjust the extraction temperature, pressure, time, control CO 2 Flow rate for extraction, wherein: the temperature of the extraction kettle is 55°C, the pressure is 30.0MPa, the time is 3h, CO 2 The flow rate is 20L / h. Add entrainer ethanol (entrainer: the volume-to-weight ratio of fine powder is 3: 1 (L: Kg) in the extraction tank, and its flow rate is set at 2L / h. Then the first separating tank separation temperature is set to 35 ℃, separates The pressure is set to 6MPa to carry out the first separation. Afterwards, the separation temperature of the second separat...

Embodiment 3

[0113] The mycelium obtained after fermentation of Aspergillus terreus CA951 (ie the crude product of lovastatin, purchased from Chongqing Industrial Microbiology Pharmaceutical Engineering Technology Research Center) was used as raw material, and the method described in Example 2 was used for extraction and separation. The recovery of lovastatin was determined to be 92% by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com