Adhesive resin used for steel band reinforced polyethylene spiral corrugated pipe and preparation method thereof

A polyethylene screw, bonding resin technology, applied in the direction of graft polymer adhesives, pipes/pipe joints/fittings, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problem of bonding resin maleic anhydride monomers. Residue, low production efficiency, irritating odor and other problems, to achieve the effects of high heat resistance and mechanical strength, improved production efficiency, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

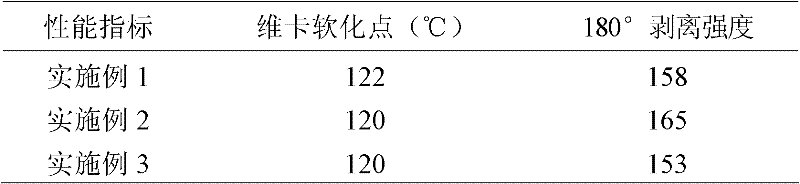

Embodiment 1

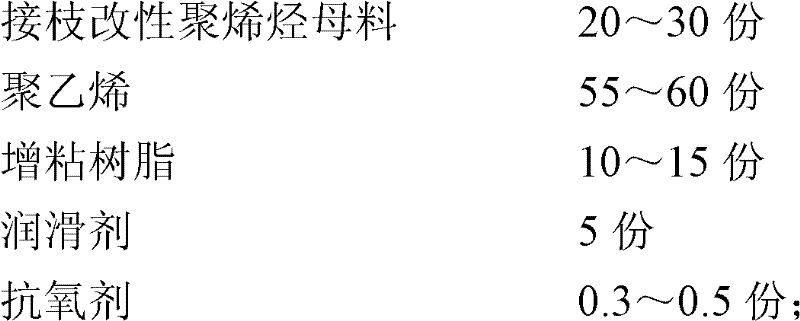

[0040] (1) Dissolve 3 parts of maleic anhydride and 0.1 parts of dicumyl peroxide (DCP) in 3.1 parts of acetone, and then mix with 50 parts of high-density polyethylene, 30 parts of linear low-density polyethylene, and 20 parts of ethylene-acetic acid Ethylene copolymer (EVA) is added together in the high-speed mixer and mixed uniformly, and finally is extruded through a twin-screw extruder to obtain a grafted modified polyolefin masterbatch; the parts are parts by weight; the twin-screw extruder The processing temperature of the machine is 180°C.

[0041] (2) 30 parts by weight of grafted modified polyolefin masterbatch, 55 parts by weight of high-density polyethylene, 5 parts by weight of petroleum resin, 5 parts by weight of SBS, 5 parts by weight of polyethylene wax and antioxidant B215 (Swiss Ciba Company) 0.3 parts by weight are added to the high-speed mixer, mixed evenly, blended and granulated through the twin-screw extruder, the processing temperature of the twin-scre...

Embodiment 2

[0043] (1) Dissolve 1 part of methacrylic acid, 0.1 part of benzoyl peroxide (BPO), and 0.2 parts of di-tert-butyl peroxide in 1.3 parts of acetone, and then mix with 50 parts of high-density polyethylene and 30 parts of low-density polyethylene Ethylene (LDPE) and 20 parts of ethylene-vinyl acetate copolymer (EVA) are added together in a high-speed mixer and mixed uniformly, and finally reacted and extruded by a twin-screw extruder to obtain a grafted modified polyolefin masterbatch; the parts The numbers are parts by weight; the processing temperature of the twin-screw extruder is 150°C.

[0044] (2) 20 parts by weight of grafted modified polyolefin masterbatch, 40 parts by weight of high-density polyethylene, 20 parts by weight of linear low-density polyethylene, 5 parts by weight of polymerized rosin, 10 parts by weight of SIS, 5 parts by weight of paraffin, anti- Oxygen 168 (Swiss Ciba) 0.1 parts by weight and 1010 (Swiss Ciba) 0.4 parts by weight are added to the high-sp...

Embodiment 3

[0046] (1) Dissolve 5 parts of acrylamide, 0.2 parts of tert-butyl hydroperoxide, and 0.3 parts of cumene hydroperoxide in 5.5 parts of acetone, and then mix with 50 parts of high-density polyethylene, 30 parts of linear low-density polyethylene, 20 parts of ethylene-vinyl acetate copolymers (EVA) are added together in a high-speed mixer and mixed uniformly, and finally reacted and extruded by a twin-screw extruder to obtain a grafted modified polyolefin masterbatch; the parts are parts by weight ; The processing temperature of the twin-screw extruder is 200°C.

[0047] (2) 25 parts by weight of grafted modified polyolefin masterbatch, 40 parts by weight of high density polyethylene, 20 parts by weight of low density polyethylene, 5 parts by weight of terpene resin, 5 parts by weight of butadiene rubber, 5 parts by weight of microcrystalline wax Parts by weight and 0.4 parts by weight of antioxidant B225 (Swiss Ciba) are added together in a high-speed mixer, mixed evenly, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com