Polylactic acid antibacterial nanofiber membrane and preparation method thereof

A nanofiber film and nanofiber technology, applied in fiber treatment, fiber chemical characteristics, spinning solution preparation, etc., can solve problems such as easy oxidation, easy aggregation of ultrafine particles, and color of tea polyphenols

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

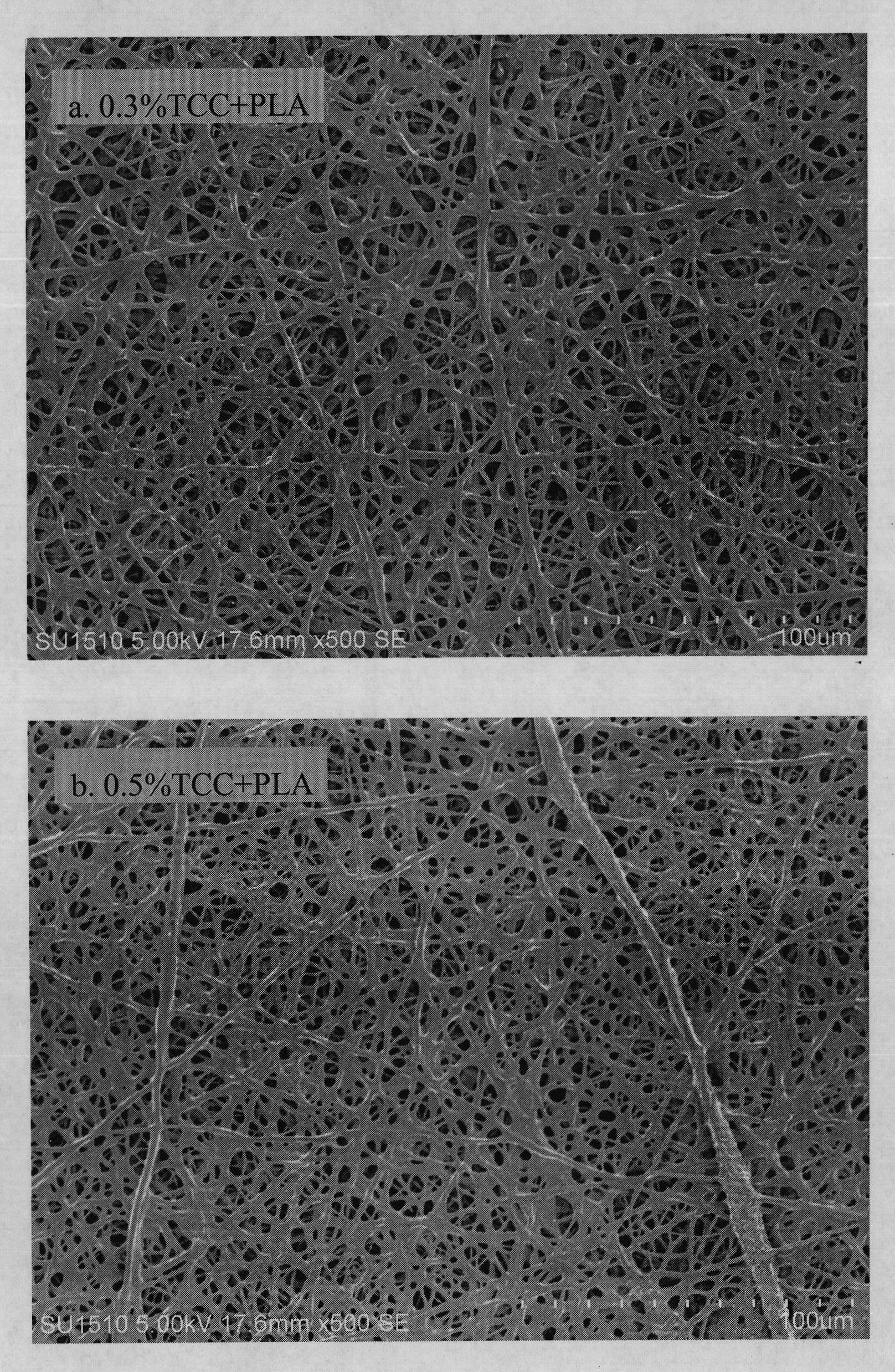

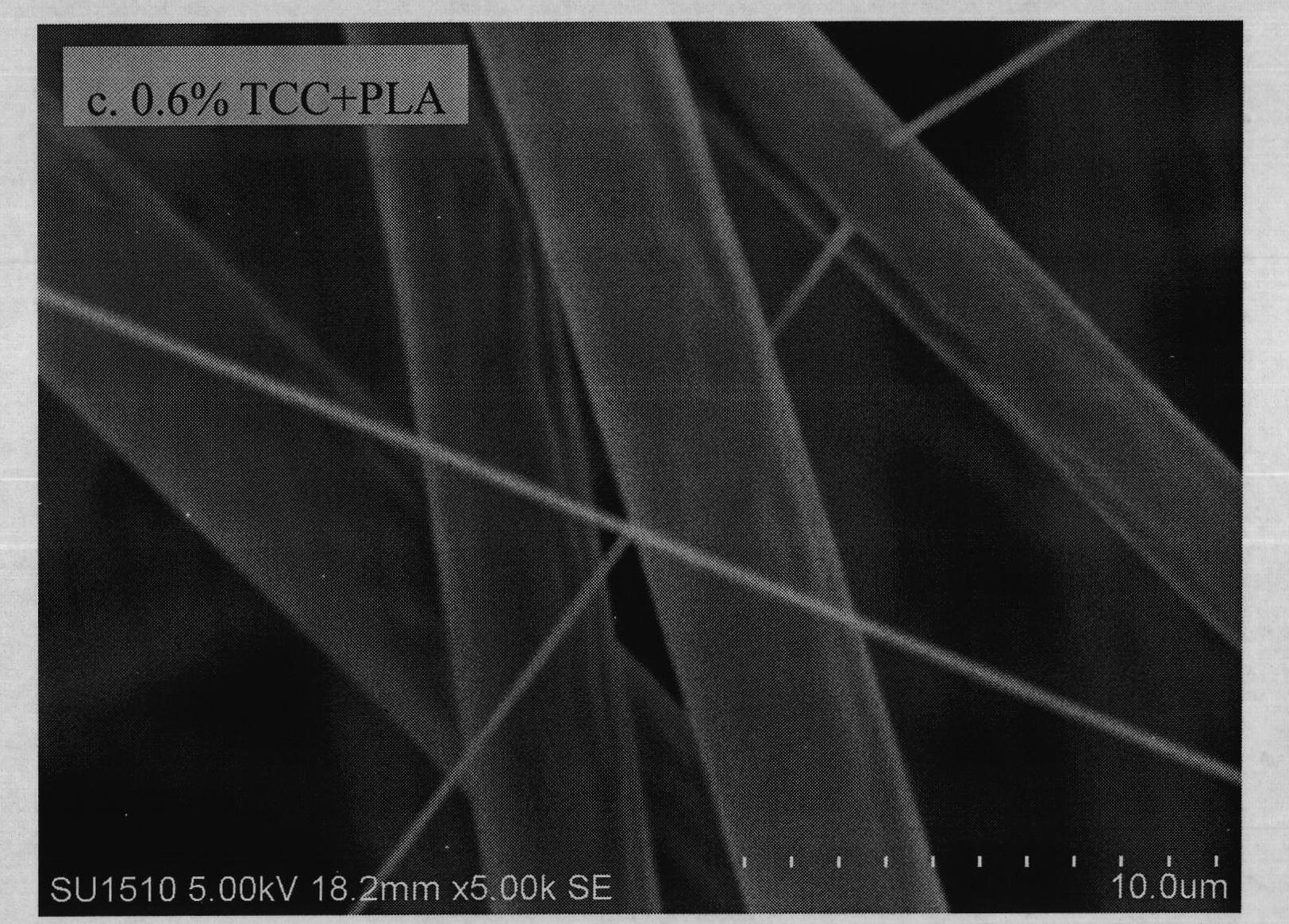

[0024] Preparation of antibacterial nanofiber material: take 2mL polyethylene glycol 400 (density is 1g / cm 3 ) into a stoppered Erlenmeyer flask, then add 170.0 mg of TCC to it, heat it at 50°C to dissolve it, then add 18 mL of dichloromethane (density 1.32 g / cm 3 ), then add 2.570g of PLLA (molecular weight: 100,000) slices into it, and stir magnetically at room temperature for 3h. Put the prepared spinning solution into an extruder equipped with a capillary (inner diameter: 0.7mm), and control the voltage Be 10kV, extrusion speed is 1mL / h, obtains the white PLLA nanofiber film on the plane receiving screen of distance from spinneret 12cm place. The antibacterial performance of the nanofiber membrane was tested by the improved shaking flask method. The antibacterial rate was evaluated according to GB-15979-2002 "Hygienic Standards for Disposable Sanitary Products". The antibacterial test results are shown in Table 1.

example 2

[0026] Preparation of antibacterial nanofiber material: take 2mL polyethylene glycol 400 (density is 1g / cm 3 ) into a stoppered Erlenmeyer flask, then add 141.7mg of TCC to it, heat it at 50°C to dissolve it, then add 18mL of dichloromethane (density 1.32g / cm 3 ), then add 2.570g of PLLA (molecular weight: 100,000) slices into it, and stir magnetically at room temperature for 3h. Put the prepared spinning solution into an extruder equipped with a capillary (inner diameter: 0.7mm), and control the voltage Be 10kV, extrusion speed is 1mL / h, obtains the white PLLA nanofiber film on the plane receiving screen of distance from spinneret 12cm place. The antibacterial performance of the nanofiber membrane was tested by the improved shaking flask method. The antibacterial rate was evaluated according to GB-15979-2002 "Hygienic Standards for Disposable Sanitary Products". The antibacterial test results are shown in Table 1.

example 3

[0028] Preparation of antibacterial nanofiber material: take 2mL polyethylene glycol 400 (density is 1g / cm 3 ) into a stoppered Erlenmeyer flask, then add 113.3 mg of TCC to it, heat it at 50°C to dissolve it, then add 18 mL of dichloromethane (density 1.32 g / cm 3 ), then add 2.570g of PLLA (molecular weight: 100,000) slices into it, and stir magnetically at room temperature for 3h. Put the prepared spinning solution into an extruder equipped with a capillary (inner diameter: 0.7mm), and control the voltage Be 10kV, extrusion speed is 1mL / h, obtains the white PLLA nanofiber film on the plane receiving screen of distance from spinneret 12cm place. The antibacterial performance of the nanofiber membrane was tested by the improved shaking flask method. The antibacterial rate was evaluated according to GB-15979-2002 "Hygienic Standards for Disposable Sanitary Products". The antibacterial test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com