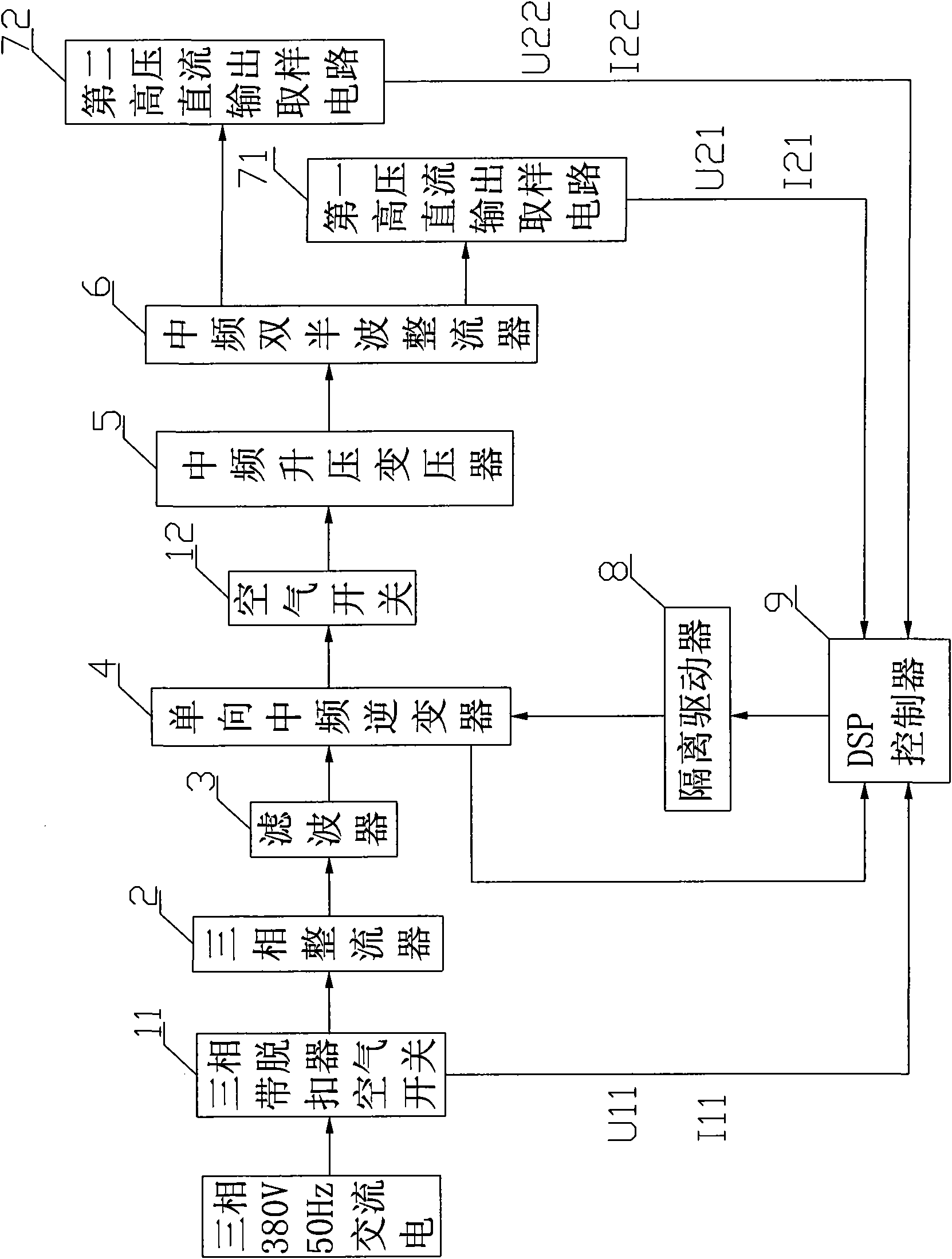

Intelligent medium-frequency high-voltage double-output direct current power supply for electric dust removal

A DC power supply, high-voltage DC technology, applied in the field of high-voltage electrostatic dust removal, can solve the problems of non-compliance with sustainable development, grid electromagnetic interference, large output ripple, etc., to improve power utilization efficiency, grid input balance, and high output voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

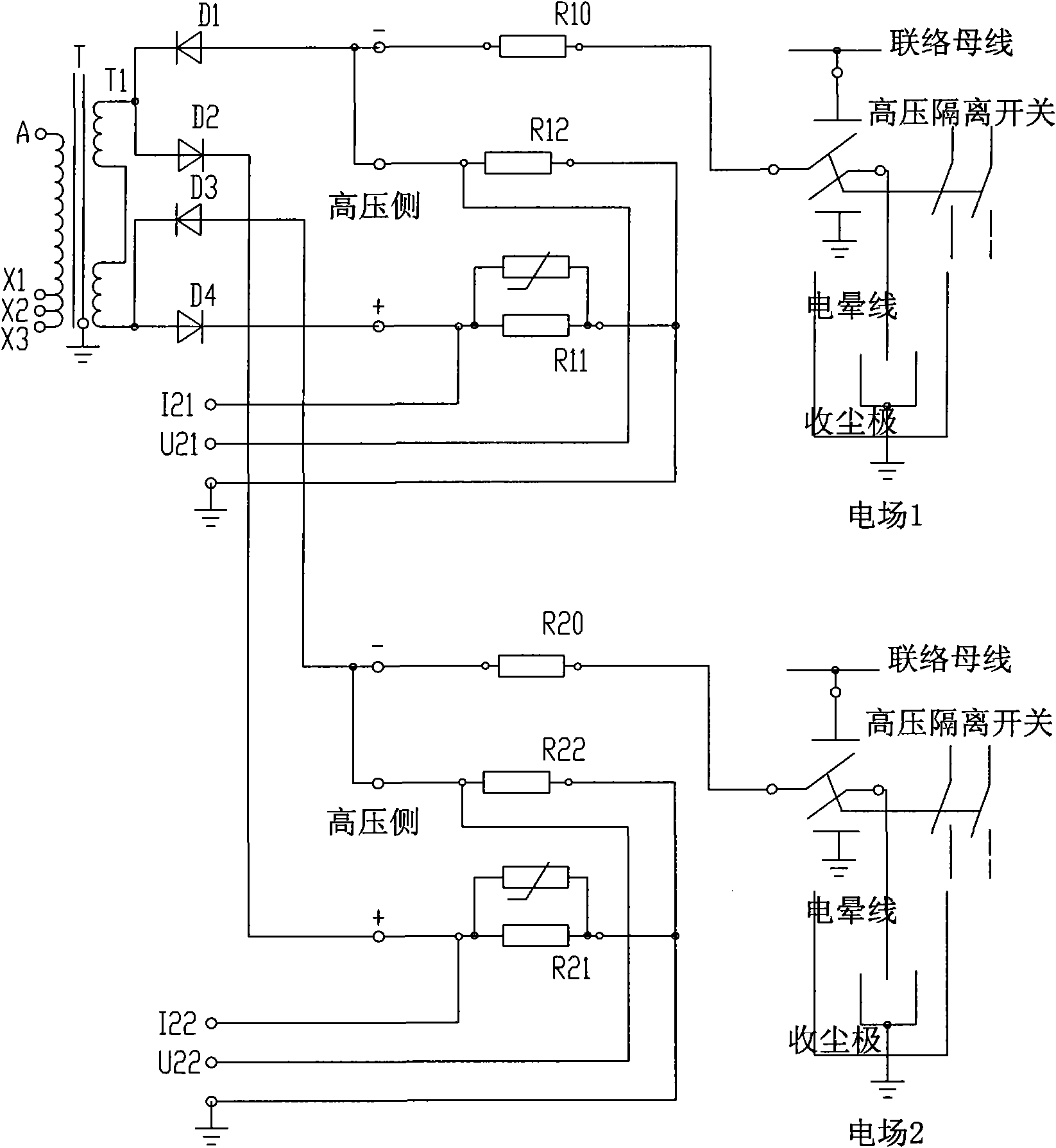

[0042] Embodiment 1, an intelligent medium-frequency high-voltage dual-output DC power supply for electric dust removal according to the present invention can provide power for two electric fields at the same time. For the schematic diagram of some circuit connections, please refer to figure 2 As shown, it can provide power to electric field 1 and electric field 2 at the same time. The intermediate frequency step-up transformer 5 of the present invention includes a secondary winding T1; the intermediate frequency double half-wave rectifier 6 is composed of a diode D1, a diode D2, a diode D3 and a diode D4; the first high voltage DC output sampling circuit 71 is composed of a first current sampling resistor R11 and The first voltage sampling resistor R12 is formed; the second high-voltage direct current output sampling circuit 72 is composed of the second current sampling resistor R21 and the second voltage sampling resistor R22; one end of the secondary winding T1 is connected...

Embodiment 2

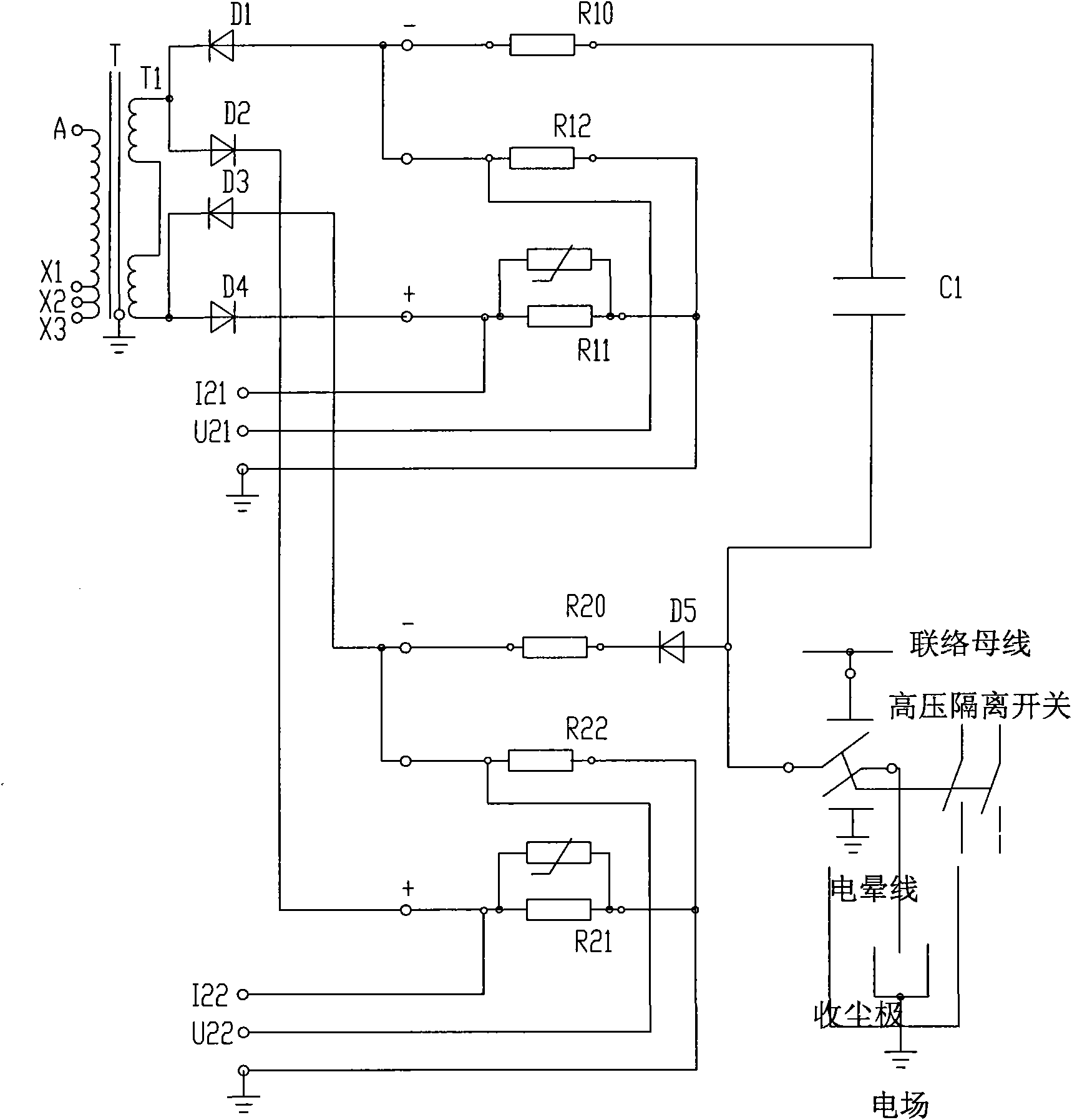

[0044] Embodiment 2, an intelligent medium-frequency high-voltage dual-output DC power supply for electric dust removal according to the present invention, which can supply an electric field pulse and a DC dual-circuit power supply. For a schematic diagram of some circuit connections, please refer to image 3 shown. The intermediate frequency step-up transformer 5 of the present invention includes a secondary winding T1; the intermediate frequency double half-wave rectifier 6 is composed of a diode D1, a diode D2, a diode D3 and a diode D4; the first high voltage DC output sampling circuit 71 is composed of a first current sampling resistor R11 and The first voltage sampling resistor R12 is formed; the second high-voltage direct current output sampling circuit 72 is composed of the second current sampling resistor R21 and the second voltage sampling resistor R22; one end of the secondary winding T1 is connected to the cathode of the diode D1 and the anode of the diode D2 respec...

Embodiment 3

[0046] Embodiment 3, an intelligent medium-frequency high-voltage dual-output DC power supply for electric dust removal according to the present invention can also provide power for a lens-type dust removal system. For a schematic diagram of some circuit connections, please refer to Figure 4 shown. The intermediate frequency step-up transformer 5 of the present invention includes a secondary winding T1; the intermediate frequency double half-wave rectifier 6 is composed of a diode D1, a diode D2, a diode D3 and a diode D4; the first high voltage DC output sampling circuit 71 is composed of a first current sampling resistor R11 and The first voltage sampling resistor R12 is formed; the second high-voltage direct current output sampling circuit 72 is composed of the second current sampling resistor R21 and the second voltage sampling resistor R22; one end of the secondary winding T1 is connected to the cathode of the diode D1 and the anode of the diode D2 respectively. The othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com