Method and device for directly recovering oxalate precipitate of waste acid

A technology of oxalate and waste acid, which is applied in the direction of carboxylate preparation, carboxylate preparation, nitric acid, etc., can solve the problems of many equipments and long treatment process, and achieve short process, low operating cost and low consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one: carry out oxalic acid precipitation by dysprosium chloride solution to obtain dysprosium oxalate and reclaim hydrochloric acid

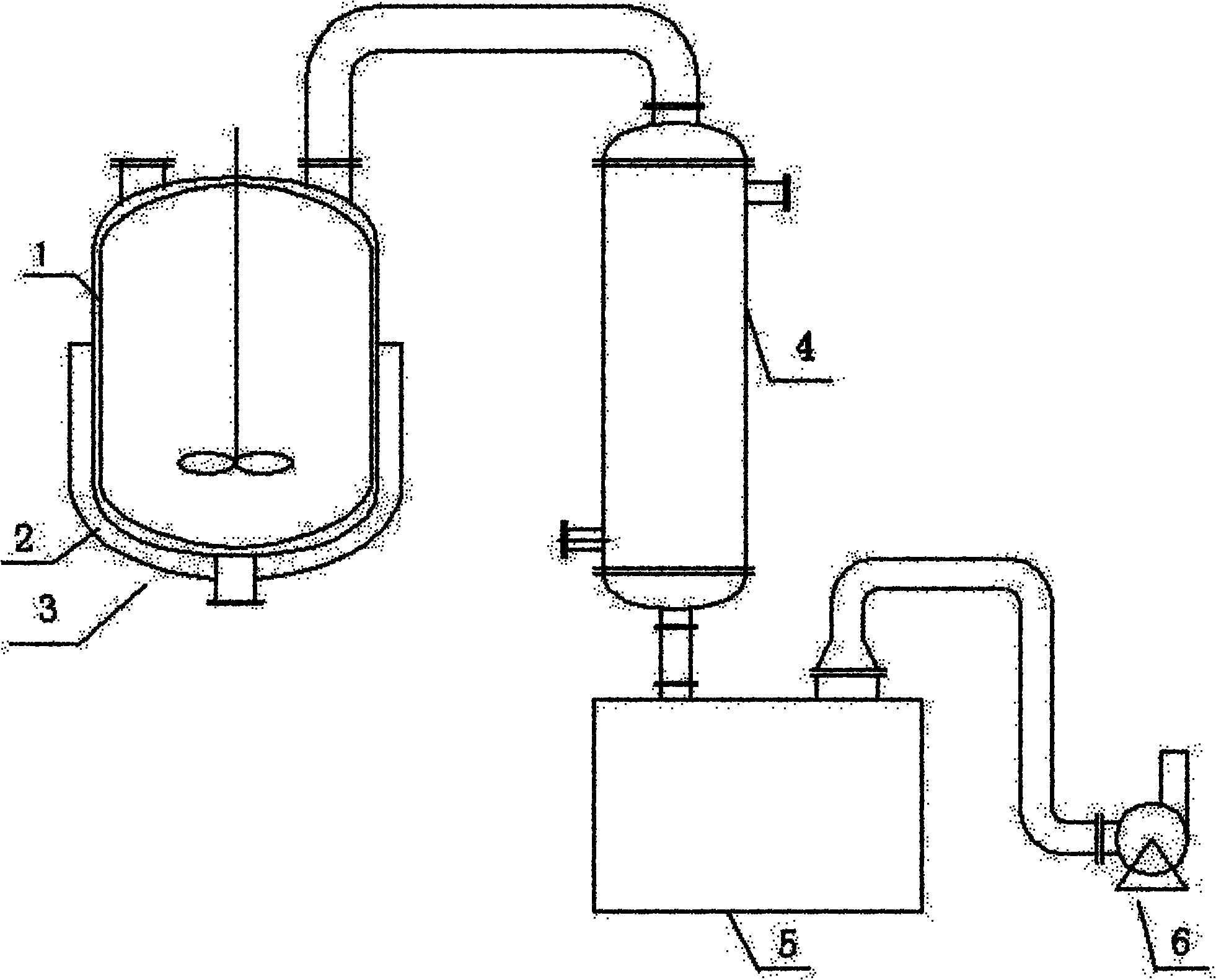

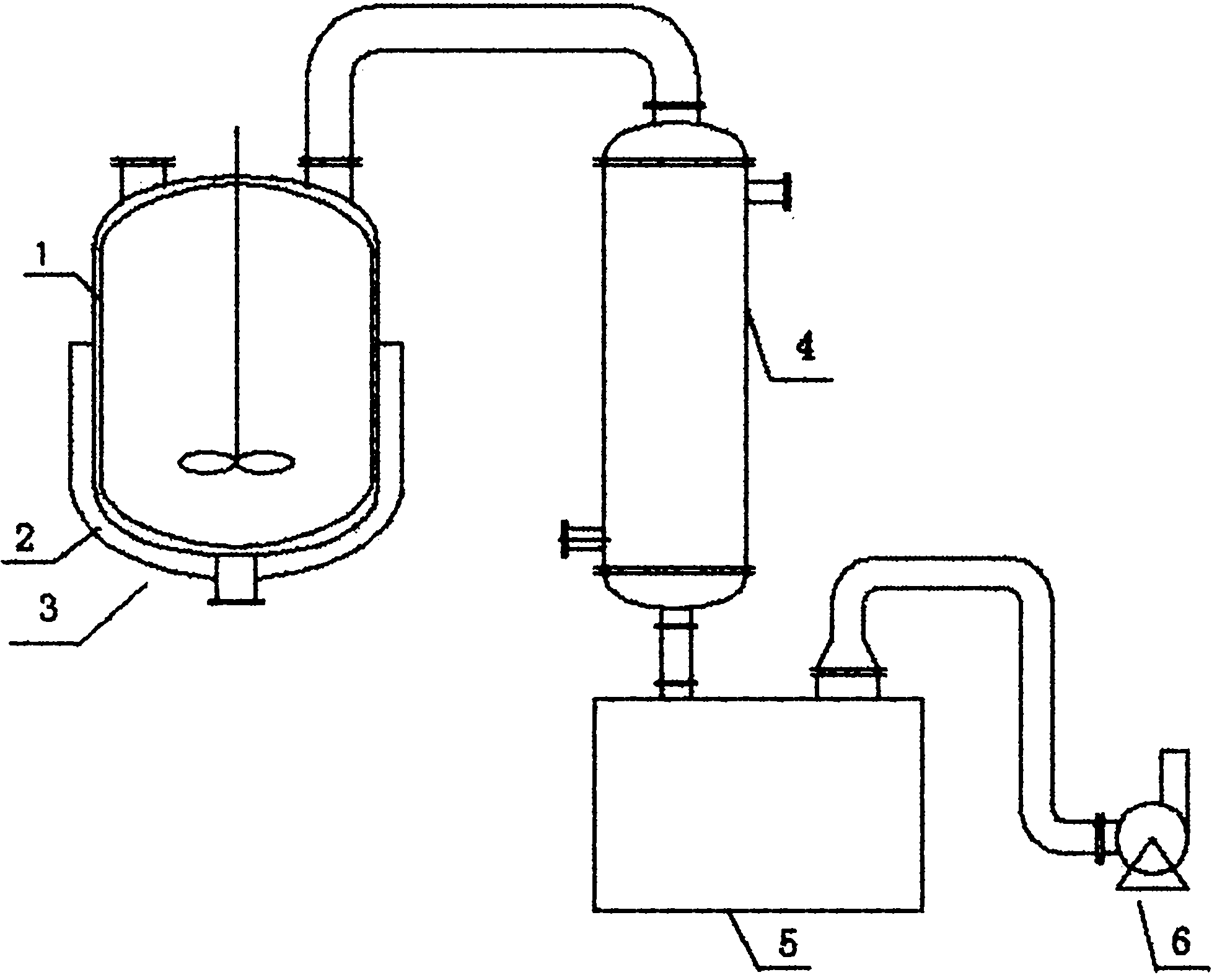

[0031] see figure 1 , the precipitation distillation pot, which is composed of a polytetrafluoroethylene-lined kettle body, a stirrer loaded from the top of the kettle body, and a far-infrared heater installed at the bottom of the kettle body, and the condenser, collector, and vacuum pump are sequentially used to compact pipe fittings Connect to form precipitation distillation equipment.

[0032] Among them, the internal parts of the precipitation distillation pot, the surface of the pipe fittings between the precipitation distillation pot and the condenser and the material contact surface are all lined with polytetrafluoroethylene; the condenser adopts graphite modified PP cold heat exchanger; the collector and the pipe fittings between the collector and the vacuum pump adopt Lined with polytetrafluoroethylene material.

[0...

Embodiment 2

[0035] Embodiment two: cobalt acetate solution carries out oxalic acid precipitation to obtain cobalt oxalate and reclaim acetic acid

[0036] see figure 1 , Precipitation distillation equipment is the same as embodiment one.

[0037] Will C Co 2+ =70g / L, C H + = 1500L cobalt acetate solution of 1mol / L, added to 2m 3In the settling distillation pot, open the far-infrared heater to make the temperature of the material in the pot rise to 60°C, and add 228KG oxalic acid solids several times while stirring. Close the feeding port of the precipitation distillation pot. Continue stirring and heating, carry out normal pressure distillation, keep the material in the pot at 107°C, stop the distillation when the content in the pot is distilled to a residual liquid≤10%, and end the distillation operation. Obtain 1475 liters of pure acetic acid of 3.20mol / L, and the recovery rate of acetic acid is 93.30%. Add 1500L of hot water obtained by heat exchange in the condenser into the p...

Embodiment 3

[0039] Embodiment three: neodymium nitrate solution carries out oxalic acid precipitation to obtain neodymium oxalate and reclaim nitric acid

[0040] see figure 1 , Precipitation distillation equipment is the same as embodiment one.

[0041] Will C H + =0.360mol / L, C REO =1.462mol / L (REO=245.91g / L), 1500L of neodymium nitrate solution was added to 2m 3 In the precipitation distillation pot, add 419KG solid oxalic acid several times under normal temperature and stirring conditions. Close the feeding port of the precipitation distillation pot. Continue to stir and turn on the far-infrared heater to raise the temperature of the material in the pot to 80°C, turn on and adjust the water ring vacuum system, carry out vacuum distillation, keep the material in the pot between 90 and 100°C, and distill until the remaining in the precipitation distillation pot Stop distillation when liquid≤10%, obtain the nitric acid of 1465 liters 4.46mol / L. The recovery rate of nitric acid is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com