Graphene-polyaniline composite material and preparation method thereof

A composite material and polyaniline technology are applied in the field of graphene-polyaniline composite materials and their preparation, and can solve the problems of affecting application, low specific capacity of composite fiber materials, and unimproved specific surface area of composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

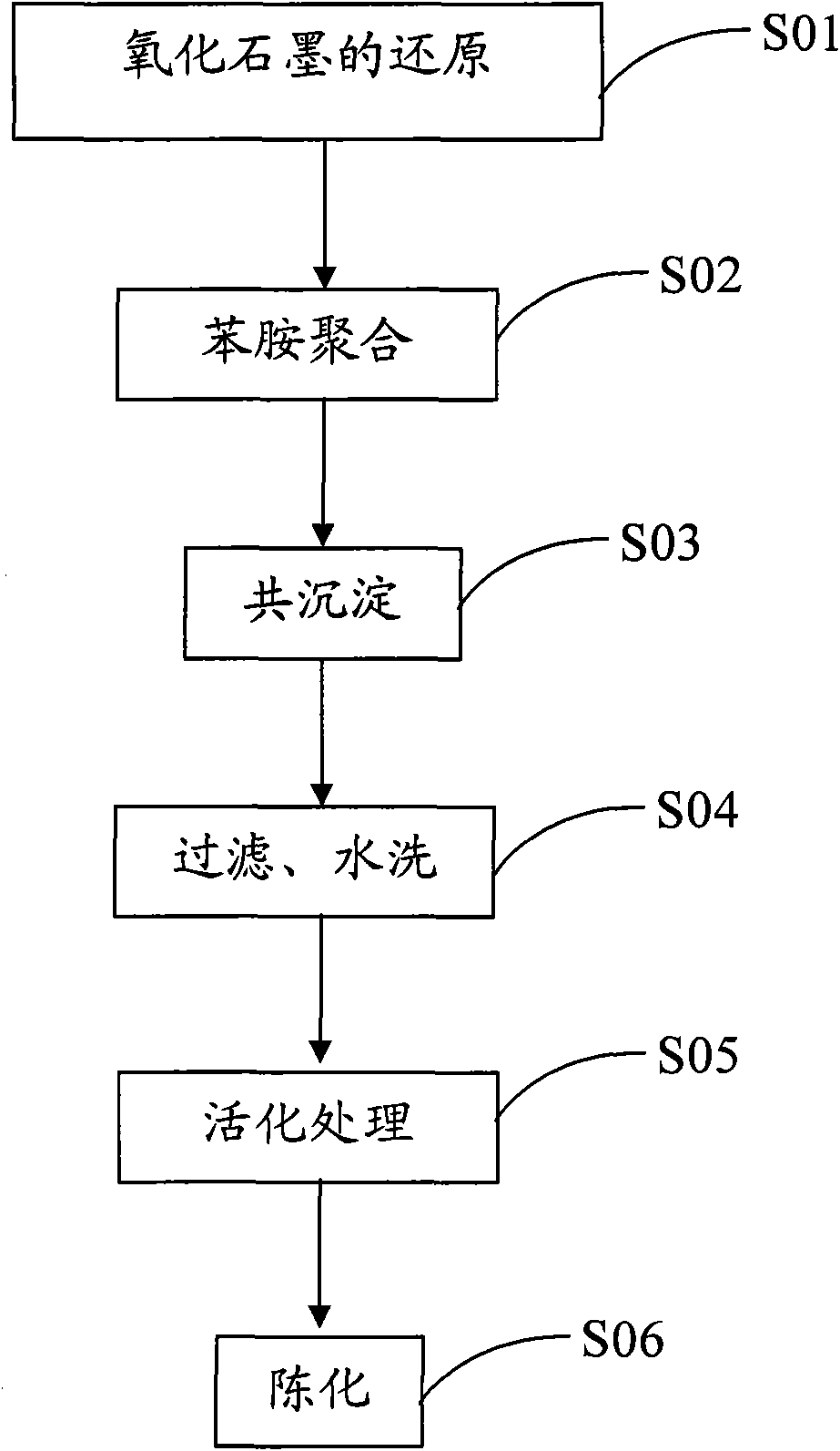

[0030] see figure 2 , showing the preparation method flow chart of the graphene-polyaniline composite material of the embodiment of the present invention, the method comprises the following steps:

[0031] S01, the reduction of graphite oxide: adding graphite oxide into a solution system, reducing the graphite oxide in an ultrasonically dispersed state with a reducing agent to form a graphene solution;

[0032] S02, aniline polymerization: adding aniline, hydrogen peroxide, ferric chloride solution and hydrochloric acid solution to the graphene solution, and ultrasonically blending to form graphene-doped polyaniline;

[0033] S03, co-precipitation: reduce the ultrasonic power of the reaction system for the polymerization of aniline, slowly precipitate, then stop the ultrasonic oscillation, and stand still;

[0034] S04, filtering and washing with water: filtering out the obtained precipitated supernatant, and filtering and washing the filtered precipitate;

[0035] S05, activ...

Embodiment 1

[0045] The preparation method of the graphene-polyaniline composite material of present embodiment 1 specifically comprises the following steps:

[0046] (1) Graphite oxide reduction: the preparation method of graphite oxide is obtained according to the improved Hummers method, specifically as follows, get 1.5g graphite oxide and add it to the water of 200ml for ultrasonic dispersion to form a graphene oxide solution uniformly dispersed in a monolithic layer. Then, at room temperature, dropwise add 2 g of phenylhydrazine and several drops of hydrochloric acid solution to the obtained graphene oxide solution, continue ultrasonic oscillation and stir to disperse to form a mixed solution, which is reacted at room temperature for 72 hours to form graphene solution.

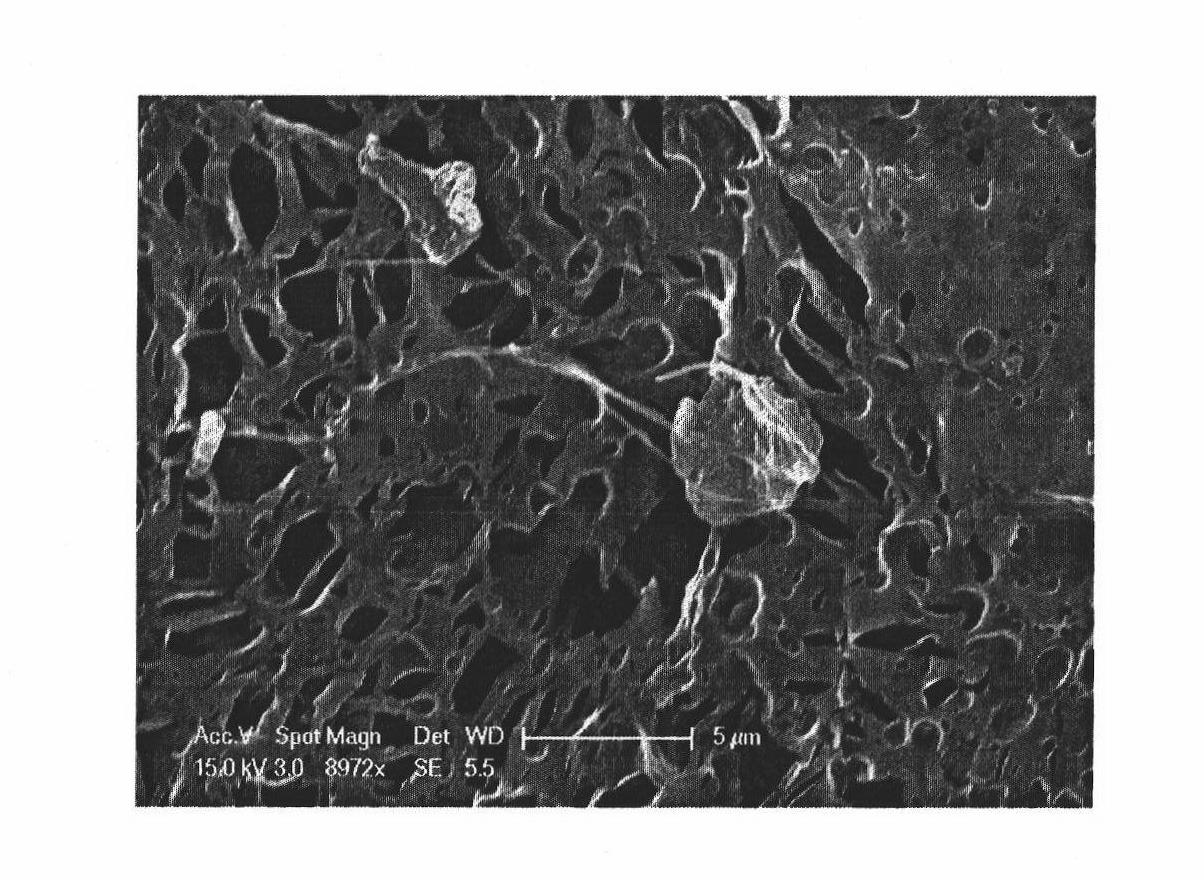

[0047] In order to detect the existence of graphene after the reaction in step (1), the graphene obtained by the reaction can be used for scanning electron microscope observation. Such as image 3 As shown, the scan...

Embodiment 2

[0054] The preparation method of the graphene-polyaniline composite material of present embodiment 2 is basically the same as embodiment 1, and the difference is that the phenylhydrazine in step (1) is replaced with other equimolar ratios of hydrazine or hydrazine hydrate, step (1) The quality of graphite oxide in ) is 2.5mg, and the quality of aniline in step (2) is 2g, then other steps and process conditions are basically the same, finally obtain the composite material of the present embodiment, polyaniline is P-type doped in this composite material The mass fraction of graphene in the composite material is about 0.10%, and the mass fraction of polyaniline is about 99.90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com