SiOC porous ceramic supported La0.9K0.1CoO3 nano particle catalyst and preparation method

A technology of nano-particles and porous ceramics is applied in the field of perovskite catalysts to achieve the effects of simple preparation process, high thermal stability and high chemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

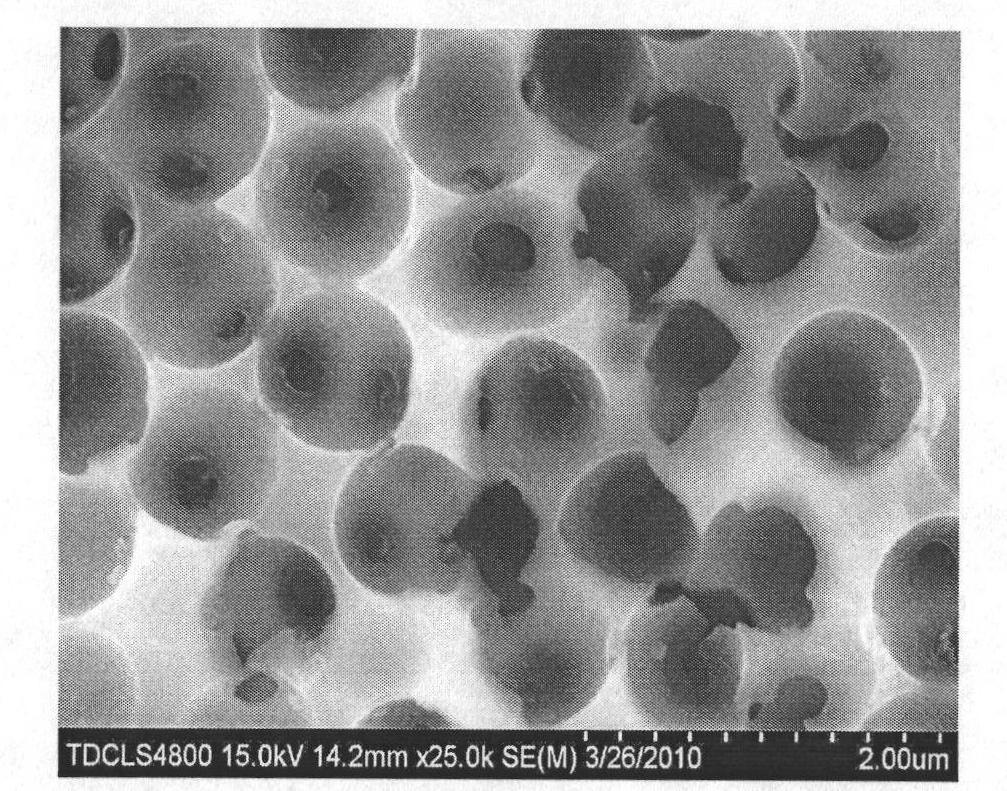

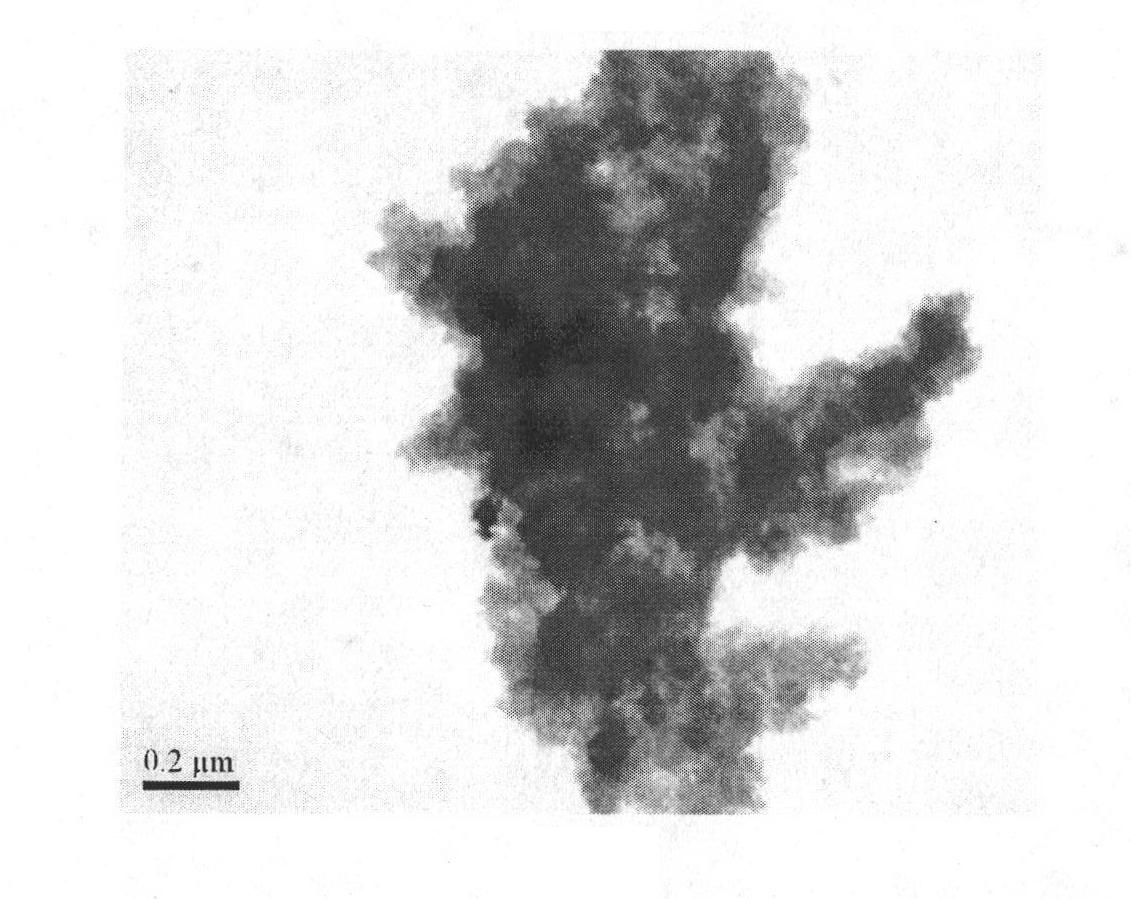

[0017] Weigh 12.9906g La(NO 3 )·6H 2 O, 0.3271g CH 3 COOK, 8.3030g Co(CH 3 COO) 2 4H 2 O and 13.2113 g of glucose were dissolved in 100 ml of deionized water. Water bath at 80°C for three days, and dry gel was obtained after cooling. Roast the dry gel in a muffle furnace: raise the temperature to 120°C at a rate of 3°C / min, keep it for 30 minutes, raise it to 400°C at a rate of 2°C / min, keep it for 2 hours, and then heat it at 10°C / min The heating rate was increased to 800 ° C, kept for 2 h, and then cooled to room temperature with the furnace to obtain the perovskite catalyst La 0.9 K 0.1 CoO 3 , grind for later use. Weigh 2g La 0.9 K 0.1 CoO 3 Pour 2ml of oleic acid into a 100ml beaker, sonicate for 20min, add ammonia water until the pH of the solution is 6; magnetically stir at room temperature for 2h, sonicate for 10min; dry the mixture in an oven at 50°C for 10h to obtain OA@La 0.9 K 0.1 CoO 3 . Weigh 2.5g OA@La 0.9 K 0.1 CoO 3 , 30mg K 2 S 2 o 8 Pou...

Embodiment 2

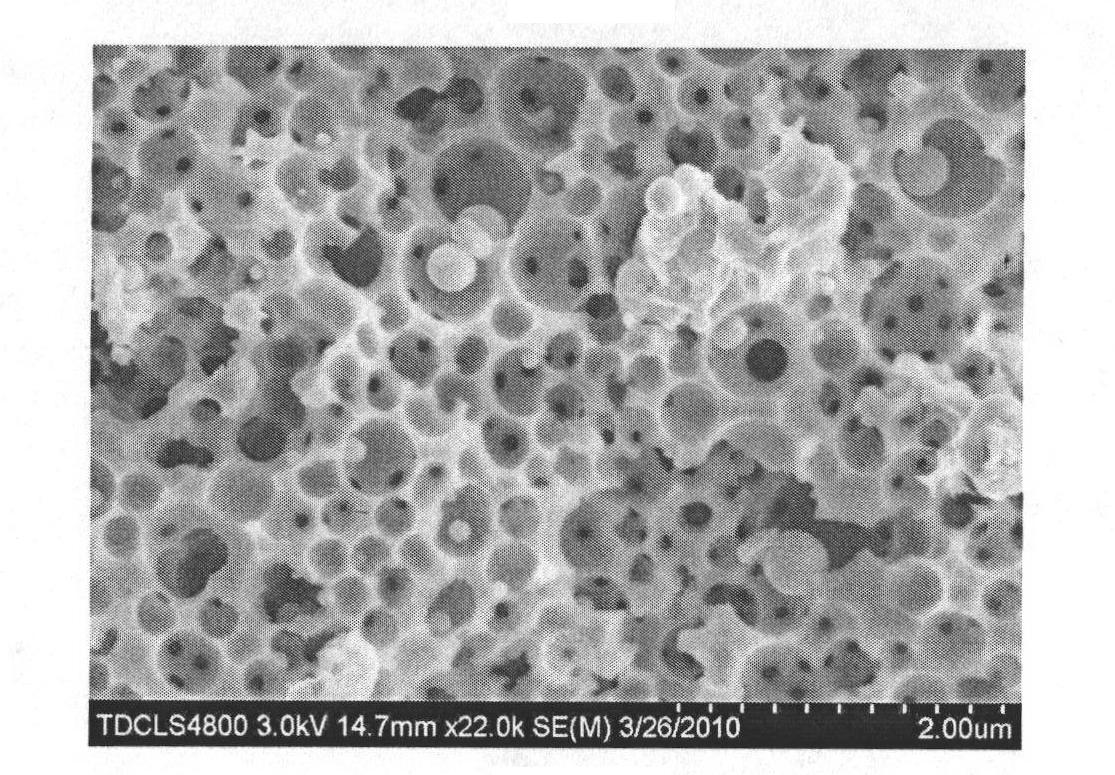

[0019] La in this example 0.9 K 0.1 CoO 3 Nanoparticle preparation and La 0.9 K 0.1 CoO 3 The nanoparticle modification steps are the same as in Example 1. The difference is: weigh 1g PHMS and 1g D 4 Pour Vi into a 25ml beaker, sonicate for 10min, put in a stirrer, stir magnetically at room temperature for 1h, add 0.02g of methyl vinyl siloxane coordination platinum catalyst, and continue stirring for 1h; add 0.2g of PS@La to the above system 0.9 K 0.1 CoO 3 , mixed, and magnetically stirred for 45 minutes; pour the precursor liquid into a glass mold, put it into a constant temperature oven, set the temperature at 50°C, keep it for 4 hours, then raise the temperature to 80°C, keep it for 2 hours, take out the crosslinked body from the mold after cooling, put it in Crystallization dish for pyrolysis; put the cross-linked body in an alumina crucible and place it in the constant temperature zone of a high-temperature tube furnace; control the gas flow rate within the rang...

Embodiment 3

[0021] La in this example 0.9 K 0.1 CoO 3 Nanoparticle preparation and La 0.9 K 0.1 CoO 3 The nanoparticle modification steps are the same as in Example 1. The difference is: weigh 1g PHMS and 1g D 4 Vi was poured into a 25ml beaker, ultrasonicated for 10min, put into a stirrer, stirred magnetically at room temperature for 1h, added 0.02g of methyl vinyl siloxane coordination platinum catalyst, and continued to stir for 1h; added 0.4g of modified La 0.9 K 0.1 CoO 3 (PS@La 0.9 K 0.1 CoO 3 ), mixed, and magnetically stirred for 45 minutes; pour the precursor liquid into a glass mold, put it into a constant temperature oven, set the temperature at 50°C, keep it for 4 hours, then raise the temperature to 80°C, keep it for 2 hours, take out the cross-linked body from the mold after cooling, put Put the cross-linked body into the crystallization dish for pyrolysis; put the cross-linked body in the alumina crucible, and place it in the constant temperature zone of the hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com