Tussah silk fibroin film and preparation method thereof

A technology of tussah silk fibroin and tussah silk, which is applied in the field of natural polymer medical biomaterials, can solve the problems of tussah silk film hardness, poor mechanical properties, and affecting biocompatibility, and achieve good biocompatibility, softness good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

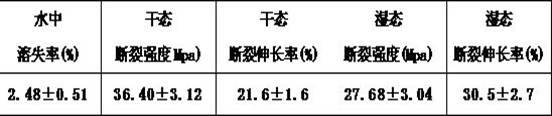

Embodiment 1

[0014] The preparation steps of the water-insoluble tussah silk fibroin film provided by the present embodiment are as follows:

[0015] 1. Put 0.1 kg of tussah raw silk into 3 liters of 0.15% sodium carbonate aqueous solution, and treat it at 98-100°C for 2 hours to degumming the raw silk, and get pure silk fibroin (ie tussah silk fibroin) after fully washing. The dried pure silk fibroin is heated and dissolved at 60±5° C. with 1 liter of lithium thiocyanate solution with a concentration of 15 mol / liter to obtain a tussah silk fibroin protein mixed solution.

[0016] 2. Using a cellulose membrane as a dialysis material, dialyze the obtained tussah silk fibroin protein mixed solution with deionized water to remove impurities such as lithium thiocyanate to obtain a tussah silk fibroin protein solution with a mass concentration of 10%.

[0017] 3. Add ethylene glycol to the above tussah silk fibroin protein solution. According to the mass ratio, the amount of ethylene glycol add...

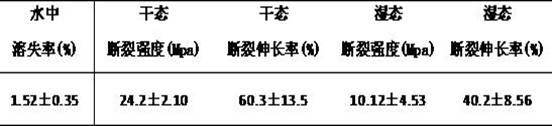

Embodiment 2

[0024] Put 0.5 kg of tussah raw silk into 25 liters of neutral soap solution with a mass concentration of 0.5%, treat it at 98-100°C for 2 hours to degumming, and get pure silk fibroin (ie tussah silk fibroin) after fully washing. The dried pure silk fibroin is dissolved with 2 liters of 16 mol / liter lithium thiocyanate aqueous solution and stirred at 60±2° C. to form a tussah silk fibroin protein mixed solution.

[0025] Using cellulose membrane as the dialysis material, the obtained tussah silk fibroin protein mixed solution was dialyzed with deionized water to remove impurities such as lithium thiocyanate to obtain a tussah silk fibroin protein solution with a mass concentration of 20%.

[0026] 1,3-propanediol is added to the pure tussah silk fibroin protein solution, and the amount of 1,3-propanediol added (according to mass ratio) is 45% of the solid content in the tussah silk fibroin protein solution.

[0027] The silk fibroin solution is injected into the mold to form ...

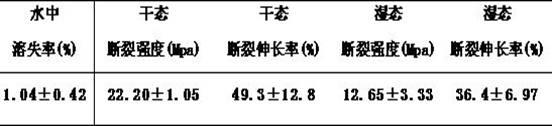

Embodiment 3

[0033] Put 200 grams of tussah raw silk into 8 liters of sodium carbonate aqueous solution with a mass concentration of 0.05%, add sodium lauryl sulfate with a mass concentration of 0.01%, and treat it at 98-100°C for 0.5 hours to degumming, repeat the treatment 3 times, and fully Pure silk fibroin is obtained after washing. The dried pure silk fibroin is heated and dissolved in 1 liter of 14 mol / liter lithium thiocyanate aqueous solution at 65±5° C. to obtain a tussah silk fibroin protein mixed solution.

[0034] Using cellulose membrane as the dialysis material, the obtained tussah silk fibroin protein mixed solution was dialyzed with deionized water for 3 days to obtain a tussah silk fibroin protein solution with a mass concentration of 16%.

[0035] Add 1,2-butanediol to the pure tussah silk fibroin protein solution, and the added amount of 1,-2 butanediol (by mass ratio) is 50% of the solid content in the tussah silk fibroin protein solution.

[0036] The silk fibroin so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com