Preparation method of monodisperse silicon oxide magnetic microspheres used for DNA purification and protein separation

A technology for protein separation and magnetic microspheres, which is applied in the fields of peptide preparation, microsphere preparation, chemical instruments and methods, etc. It can solve the problem of slow magnetic response speed, low magnetic content of microspheres, inability to meet the requirements of biological separation and purification efficiency, high Sensitivity, high throughput and other issues, to achieve the effects of size controllable, uniform particle size, and fast magnetic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

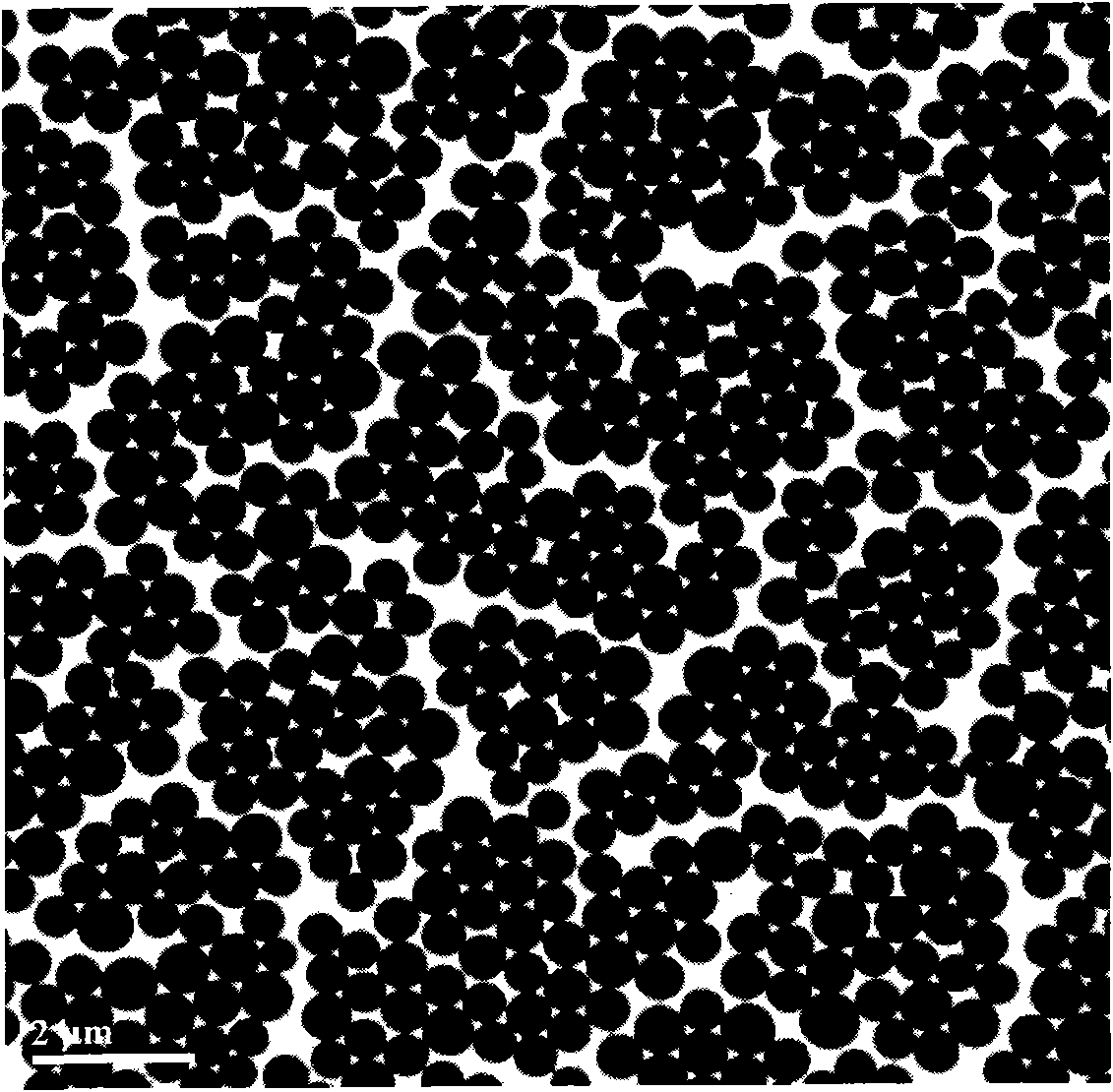

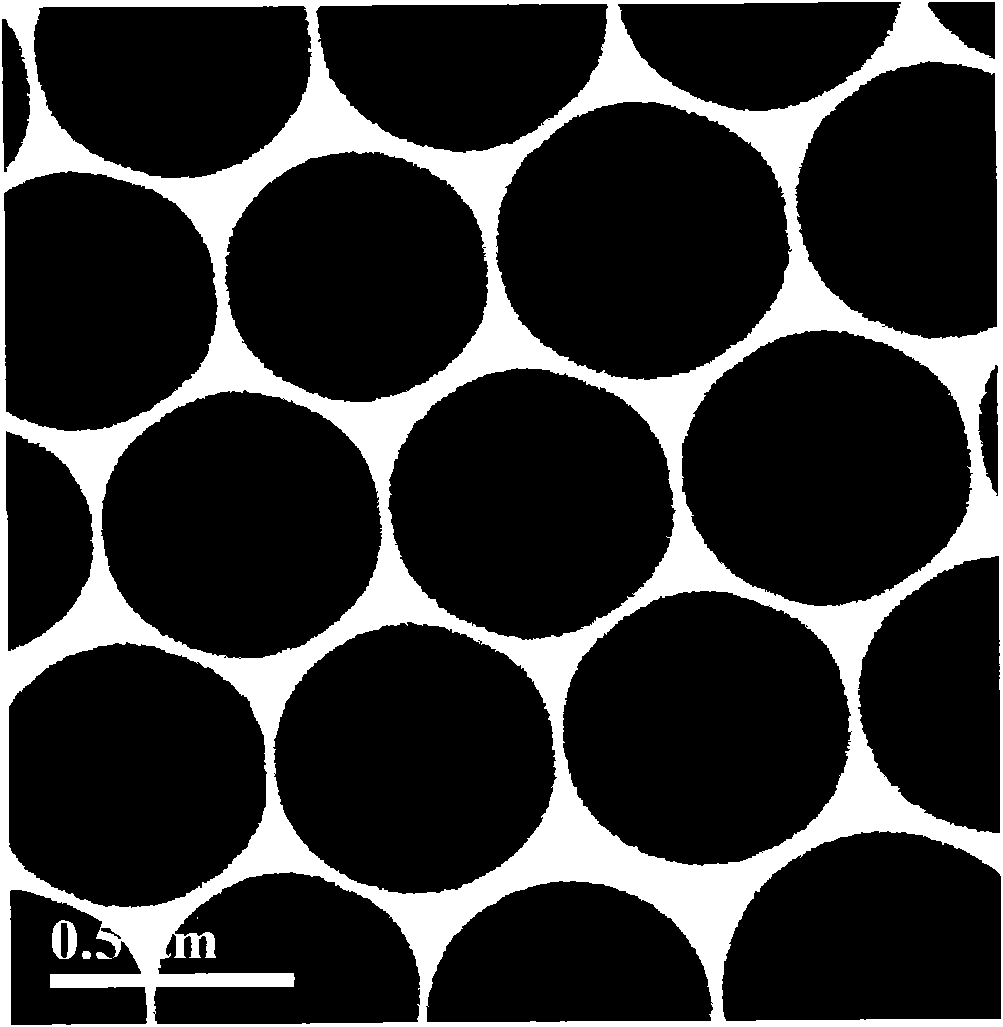

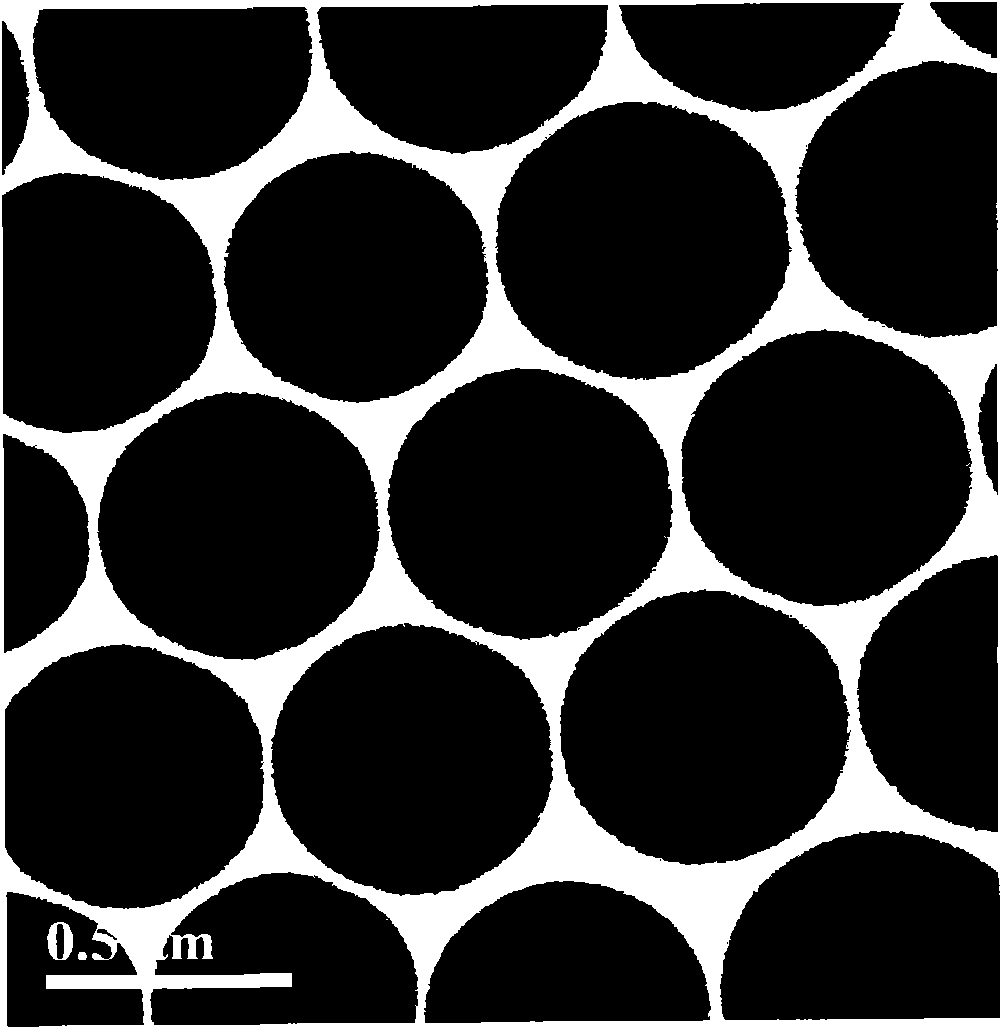

Image

Examples

Embodiment 1

[0027] 1) Preparation of Fe 3 o 4 Magnetic nanoparticles and surface modification

[0028] 50g Fe was mixed with a high-speed disperser 3 o 4 The nanoparticles were dispersed in 250ml of deionized water, mixed evenly, poured into a three-necked flask, placed in a 50°C water bath, filled with nitrogen, stirred for 0.5 hours, and then 10g of ammonia water was added to the reaction system to start the reaction. After 10 minutes 0.005 g of undecylenic acid was added. After 1 hour, raise the temperature of the water bath to 65°C, open the three-necked flask and keep it warm for 1 hour, and stop the reaction after all the ammonia water evaporates. The black solid was separated by magnetic adsorption, and then washed three times with water and absolute ethanol, and then vacuum-dried at 50°C to obtain Fe 3 o 4 Powder, spare.

[0029] 2) Preparation of Fe 3 o 4 Magnetic Nanoparticle Assemblies

[0030] SDS was dissolved in deionized water to form a 0.01 wt% aqueous solution, ...

Embodiment 2

[0036] 1) Fe 3 o 4 Preparation and surface modification of magnetic nanoparticles

[0037] 50g Fe was mixed with a high-speed disperser 3 o 4 The nanoparticles were dispersed in 250ml of deionized water, mixed evenly, poured into a three-necked flask, placed in a 75°C water bath, filled with nitrogen, stirred for 0.5 hours, and then 10g of ammonia water was added to the reaction system to start the reaction. After 10 minutes 0.5 g of octadecenoic acid was added. After 1 hour, raise the temperature of the water bath to 85°C, disperse the three-necked flask and keep it warm for 1 hour, and the reaction ends after all the ammonia water evaporates. The black solid was separated by magnetic adsorption, and then washed three times with water and absolute ethanol, and then vacuum-dried at 50°C to obtain Fe 3 o 4 Magnetic nano particle powder, spare.

[0038] 2) Preparation of Fe 3 o 4 magnetic particle assembly

[0039] Dissolve PVA in deionized water to form a 0.5 wt% aque...

Embodiment 3

[0044] 1) Fe 3 o 4 Preparation and surface modification of magnetic nanoparticles

[0045] 50g Fe was mixed with a high-speed disperser 3 o 4 The nanoparticles were dispersed in 250ml of deionized water, mixed evenly, poured into a three-neck flask, placed in a 90°C water bath, filled with nitrogen, stirred for 0.5 hours, and then 10g of ammonia water was added to the reaction system to start the reaction. After 10 minutes 10 g of linolenic acid was added. After 1 hour, raise the temperature of the water bath to 95°C, open the three-necked flask and keep it warm for 1 hour, and wait for the ammonia water to evaporate completely to end the reaction. The black solid was separated by magnetic adsorption, washed with water and absolute ethanol three times respectively, and vacuum-dried at 50° C. to obtain magnetic nanoparticle powder for future use.

[0046] 2) Preparation of magnetic particle assembly

[0047] Tween 80 was dissolved in deionized water to form a 5.0 wt% aque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com