Cationic angelica polysaccharide nanoparticle gene delivery system and preparation method thereof

A gene delivery system and cationization technology, applied in the field of cationized angelica polysaccharide nanoparticle gene delivery system, can solve the problems of inducing host immune response, limited loading capacity, and restricting wide application, etc., and achieve strong proliferation, good packaging and release Effect, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

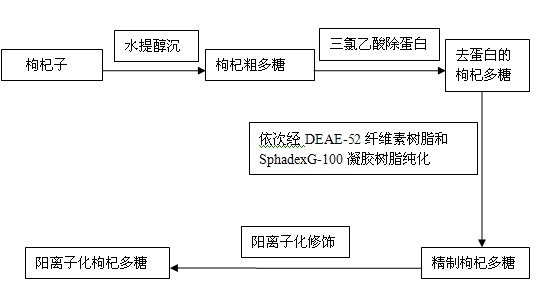

[0043] Preparation of refined angelica polysaccharide:

[0044] Take the dried root of Angelica sinensis, crush it, and extract it with water and alcohol (according to the following process: hot water extraction: material-to-liquid ratio: 1:5~20, extraction temperature: 60~90°C, extraction time 2~5h / time, extraction times: 2 times. After combining the two extracts, concentrate by rotary evaporation to 1 / 5-1 / 10 of the volume of the original extract, and then add 95% ethanol to the concentrate until the final concentration of ethanol is 65%-85%), Freeze-drying, Angelica sinensis crude polysaccharide, trichloroacetic acid method to remove protein, dialysis (molecular weight cut-off>3500Da); successively use DEAE-52 cellulose resin (eluent: double distilled water and 0.05~0.5mol / L NaOH) and SephadexG- 100 dextran gel resin (eluent: 0.1mol / LNaCl) was used to separate and purify it, and the molecular weight distribution of the isolated product was determined by gel chromatography....

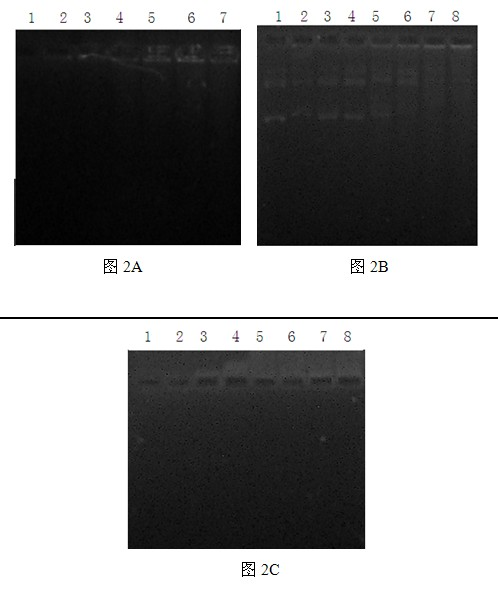

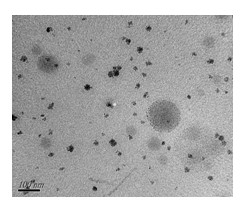

Embodiment 1

[0046] Take 0.2g refined angelica polysaccharide, dissolve it in 10ml phosphate buffer (pH=7); dissolve 0.2g carbonylimidazole, the linker for activating hydroxyl groups, in 5ml dichloromethane, and under the protection of nitrogen, first dissolve it in the polysaccharide solution Add 0.05ml of catalyst triethylamine, then slowly add the dichloromethane solution of the hydroxyl linker into the polysaccharide solution, stir at a constant speed, and complete the addition within 60 minutes. After the addition, react at room temperature for 120 minutes to obtain an activated polysaccharide solution; Molecular weight PEI was dissolved in 10ml of phosphate buffer, added catalyst triethylamine, slowly added to the activated polysaccharide solution in the dark, under the protection of nitrogen, at room temperature, the addition was completed within 120min, and reacted for 10h in the dark, at room temperature, The whole reaction was carried out under uniform stirring; after the reaction...

Embodiment 2

[0049] Take 0.8g of refined Angelica polysaccharide, dissolve it in 20ml of phosphate buffer (pH=7); Under the protection of nitrogen, first add 0.8ml of catalyst triethylamine to the polysaccharide solution, then slowly add the dichloromethane solution of the hydroxyl linker into the polysaccharide solution, stir at a constant speed, and complete the addition within 45 minutes. After the addition, react at room temperature for 90 minutes , to obtain an activated polysaccharide solution; dissolve 30 g of small molecular weight PEI in 10 ml of phosphate buffer, add catalyst triethylamine, and slowly add it to the activated polysaccharide solution in the dark, under nitrogen protection, at room temperature, and add within 150 min. After the reaction was completed, the reaction was carried out at room temperature for 10 h in the dark, and the whole reaction was carried out under constant stirring; after the reaction was completed, the solution was dialyzed (cutoff molecular weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com