Coloring composition, color filter and color liquid crystal display element

A technology of coloring composition and colorant, which is applied in the direction of optical components, instruments, optical filters, etc., and can solve problems such as difficulty in forming a flat coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0181] Examples are given below to describe the embodiment of the present invention more specifically. However, the present invention is not limited to the following examples.

[0182] Analysis of Dispersants

[0183] Dispersant (B1)

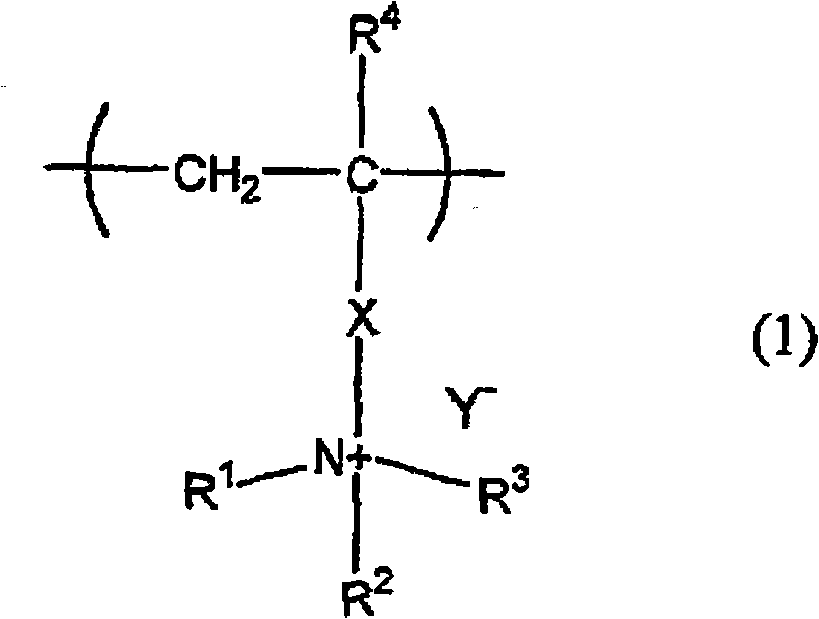

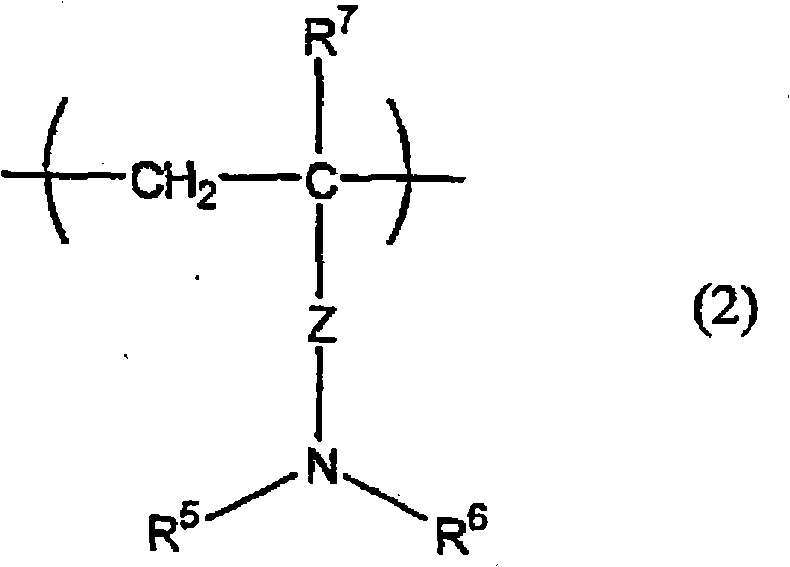

[0184] The dispersant (B1) is a commercially available product of a pigment wetting and dispersing agent, and is a solution of propylene glycol methyl ether acetate / butyl cellosolve=1 / 1 (mass ratio) of a modified acrylic block copolymer (solid content concentration 40 mass %, acid value=0). Through thermal decomposition GC-MS, FT-IR measurement, and proton NMR, it was confirmed that the dispersing agent (B1) contained The A block of the repeating unit of the ester, and the repeating A block copolymer (A / B=38 / 62) composed of B blocks of units. The copolymerization ratio of each repeating unit is methacryloxyethylbenzyldimethylammonium chloride / dimethylaminoethyl methacrylate / methyl methacrylate / butyl methacrylate / methacrylic acid 2 -Ethyl...

Synthetic example 1

[0196] 2 mass parts of 2,2'-azobisisobutyronitrile and 200 mass parts of propylene glycol monomethyl ether acetate are charged into a flask equipped with a cooling tube and a stirrer, followed by 15 mass parts of methacrylic acid, N- 20 parts by mass of phenylmaleimide, 55 parts by mass of benzyl methacrylate, 10 parts by mass of styrene and 2,4-diphenyl-4-methyl-1-pentene (Japan Nitrogen substitution was carried out in 3 parts by mass of Oils and Fats Co., Ltd. (trade name: Novoma-MSD). Thereafter, the mixture was stirred slowly to raise the temperature of the reaction solution to 80° C., and the temperature was maintained for 5 hours to perform polymerization to obtain a resin solution (solid content concentration=33% by mass). The obtained resin had Mw=16000 and Mn=7000. This resin solution is referred to as "resin solution (P1)".

[0197] Preparation of colorant dispersion

[0198] Modulation Example 1

[0199] Use 15 parts by mass of a 70 / 30 (mass ratio) mixture of ...

Embodiment 1

[0222] By adding 100 parts by mass of colorant dispersion (A-1), 3 parts by mass of resin solution (P1) as (C) binder resin (solid content concentration: 33% by mass), as (D) polyfunctional monomer 12 parts by mass of dipentaerythritol hexaacrylate, 3 parts by mass of 2-benzyl-2-dimethylamino-1-(4-morpholinophenyl) butane-1-one as (E) photopolymerization initiator 1 part by mass and 1 part by mass of 4,4'-bis(diethylamino)benzophenone, 0.1 part by mass of Megafac R08-MH (manufactured by DIC Corporation) as a fluorine-based surfactant, and 0.1 part by mass as an adhesion aid 1 mass part of 3-methacryloxypropyltrimethoxysilane, diethylene glycol monoethyl ether acetate as solvent (F1) and propylene glycol monomethyl ether acetate and acetic acid 3 as solvent (F2) -Methoxybutyl ester was mixed to prepare a liquid coloring composition (CR1) with a solid content concentration of 15% by mass. In addition, in all solvents, the content ratio of diethylene glycol monoethyl ether aceta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com