Method for synthesizing metal molybdate micron/nano materials by adopting microwave radiation method

A microwave radiation method, metal molybdate technology, applied in chemical instruments and methods, chemical/physical/physical-chemical processes of applied energy, molybdenum compounds, etc. The effect of regular appearance and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

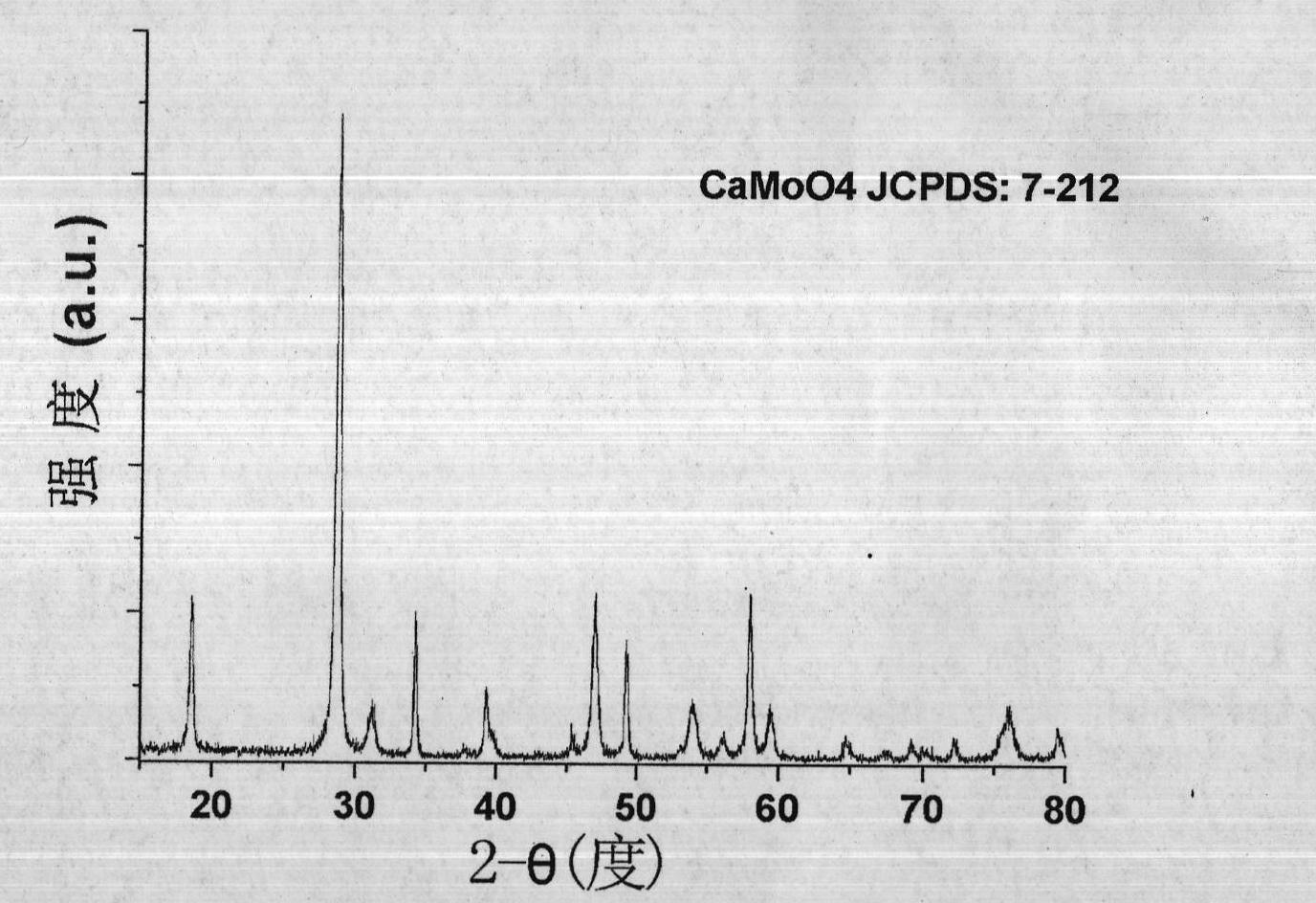

[0029] At room temperature of 25°C, prepare the molar concentration of calcium nitrate aqueous solution to be 0.100mol / L, and then add 0.050mol / L ethylenediaminetetraacetic acid to the solution to make the molar concentration of calcium nitrate and surfactant ethylenediaminetetraacetic acid The ratio is 10:5, stir vigorously for 5 minutes; weigh the ammonium molybdate solid with the molar number equal to the metal cation, add distilled water until it dissolves completely, and obtain a uniform transparent clear solution; then add it dropwise to the metal salt solution, and stir vigorously 5 minutes; the obtained solution is transferred to a glass round bottom flask, and reacted in a microwave irradiation reactor, and the reaction time is 30 minutes, and the ultrafine powder material can be prepared. The ultrafine powder was analyzed by XRD phase ( figure 1 ) indicates that it is CaMoO 4 Pure phase, the corresponding JCPDS card number is 7-212, the space group is I41 / a (No.88),...

Embodiment 2

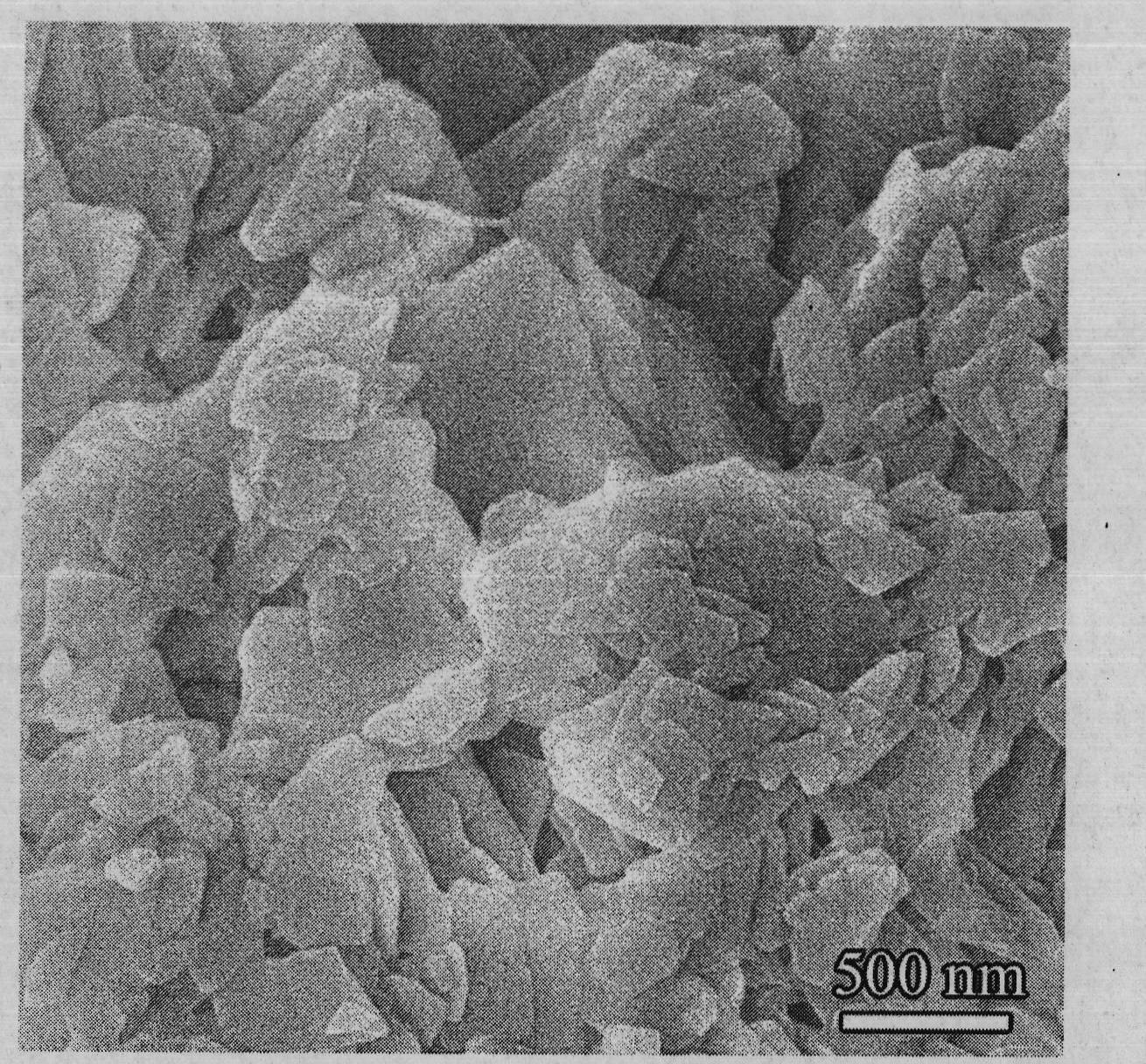

[0031] At room temperature of 25°C, prepare the molar concentration of calcium nitrate aqueous solution to be 1.000mol / L, and then add 0.100mol / L ethylenediaminetetraacetic acid to the solution to make the molar concentration of calcium nitrate and surfactant ethylenediaminetetraacetic acid The ratio is 10:1, stir vigorously for 5 minutes; weigh the ammonium molybdate solid with the molar number equal to the metal cation, add distilled water until it dissolves completely, and obtain a uniform transparent and clear solution; then add it dropwise to the metal salt solution, and stir vigorously 5 minutes; the obtained solution was transferred to a glass round-bottomed flask, and reacted in a microwave irradiation reactor for 30 minutes to prepare a pure-phase calcium molybdate material. The product was scanned by SEM ( image 3 ) shows that the main morphology of the product is nanorods, wherein a small amount of calcium molybdate nanosheets are 500-800 nanometers in diameter and...

Embodiment 3

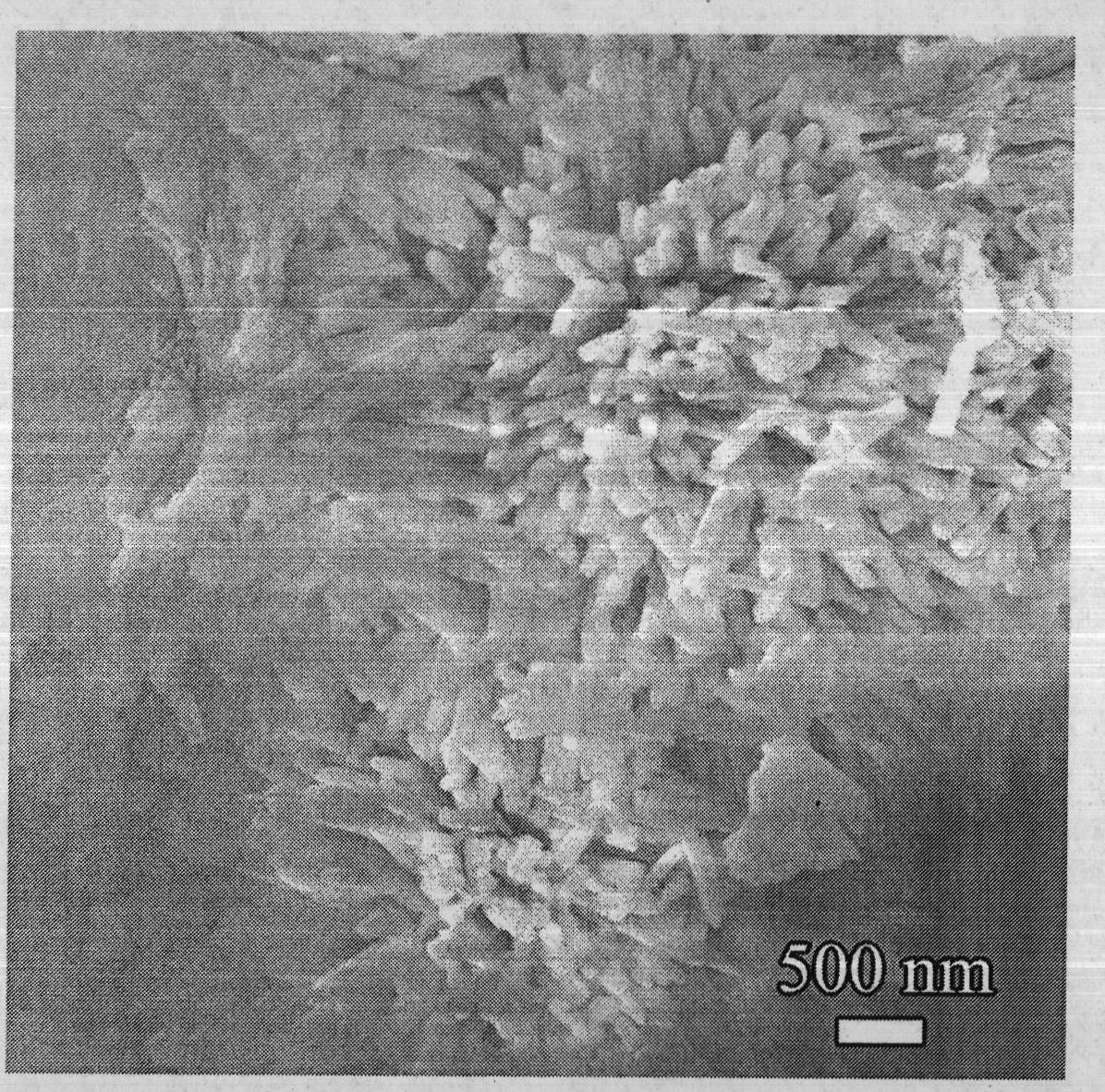

[0033] At room temperature of 25°C, configure the molar concentration of strontium nitrate aqueous solution to be 0.015mol / L, and then add 0.0015mol / L ethylenediaminetetraacetic acid to the solution to make the molar concentration of calcium nitrate and surfactant ethylenediaminetetraacetic acid The ratio is 10:1, stir vigorously for 5 minutes; weigh the ammonium molybdate solid with the molar number equal to the metal cation, add distilled water until it dissolves completely, and obtain a uniform transparent and clear solution; then add it dropwise to the metal salt solution, and stir vigorously 5 minutes; the obtained solution was transferred to a glass round-bottomed flask, and reacted in a microwave irradiation reactor for 30 minutes to prepare a pure-phase strontium molybdate material. The product was scanned by SEM ( Figure 4 ) shows that it is a nano-sheet structure, the diameter of the sheet-like material is several microns, the thickness of the sheet is 50-80 nm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com