Equipment and method for synthetizing nano material based on supergravity-ion exchange

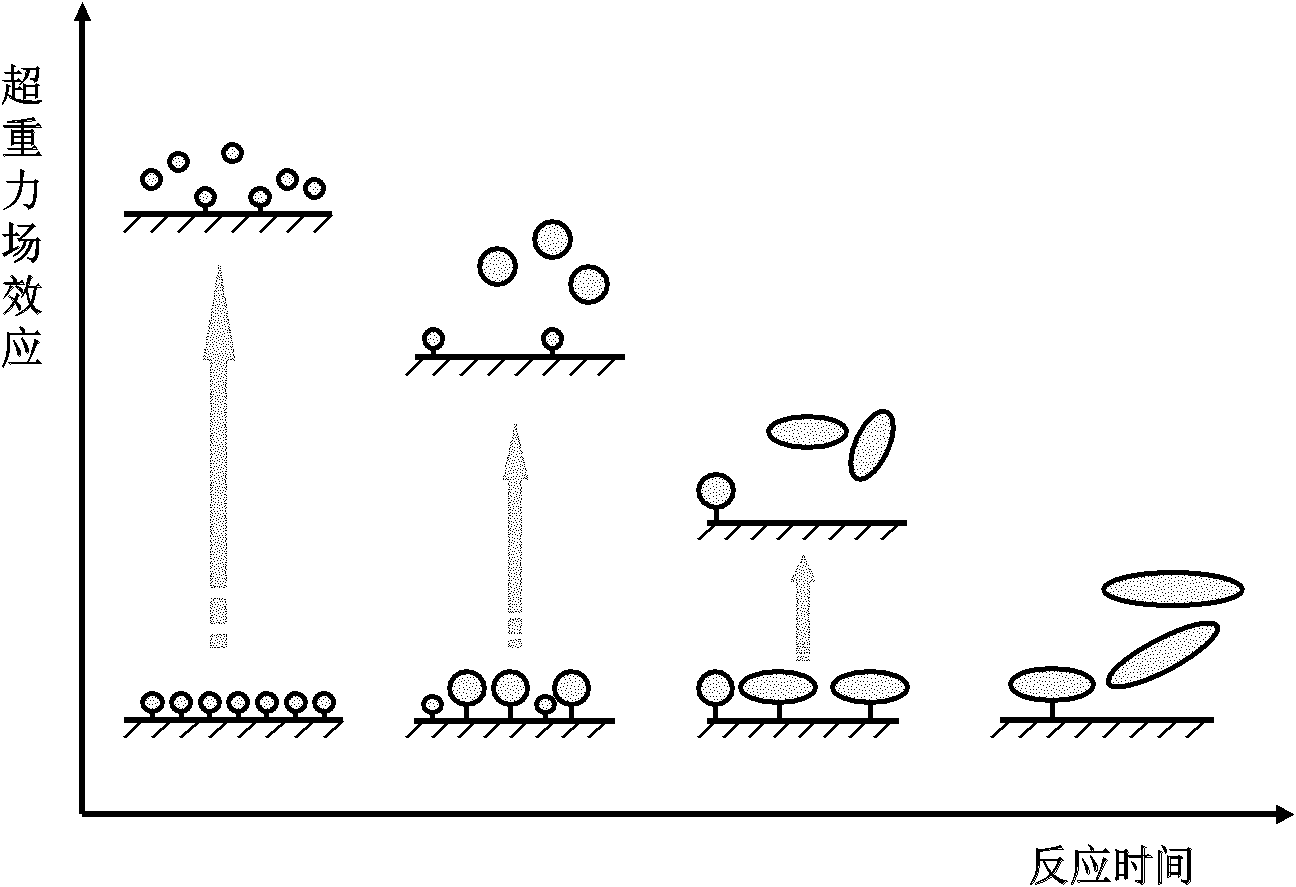

A technology of ion exchange and ion exchange fiber, which is applied in the field of high-purity nanomaterial synthesis equipment, can solve the problems of complex production equipment, waste of resources, high energy consumption, etc., and achieve the effect of simplifying the product washing process, easy industrialization, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

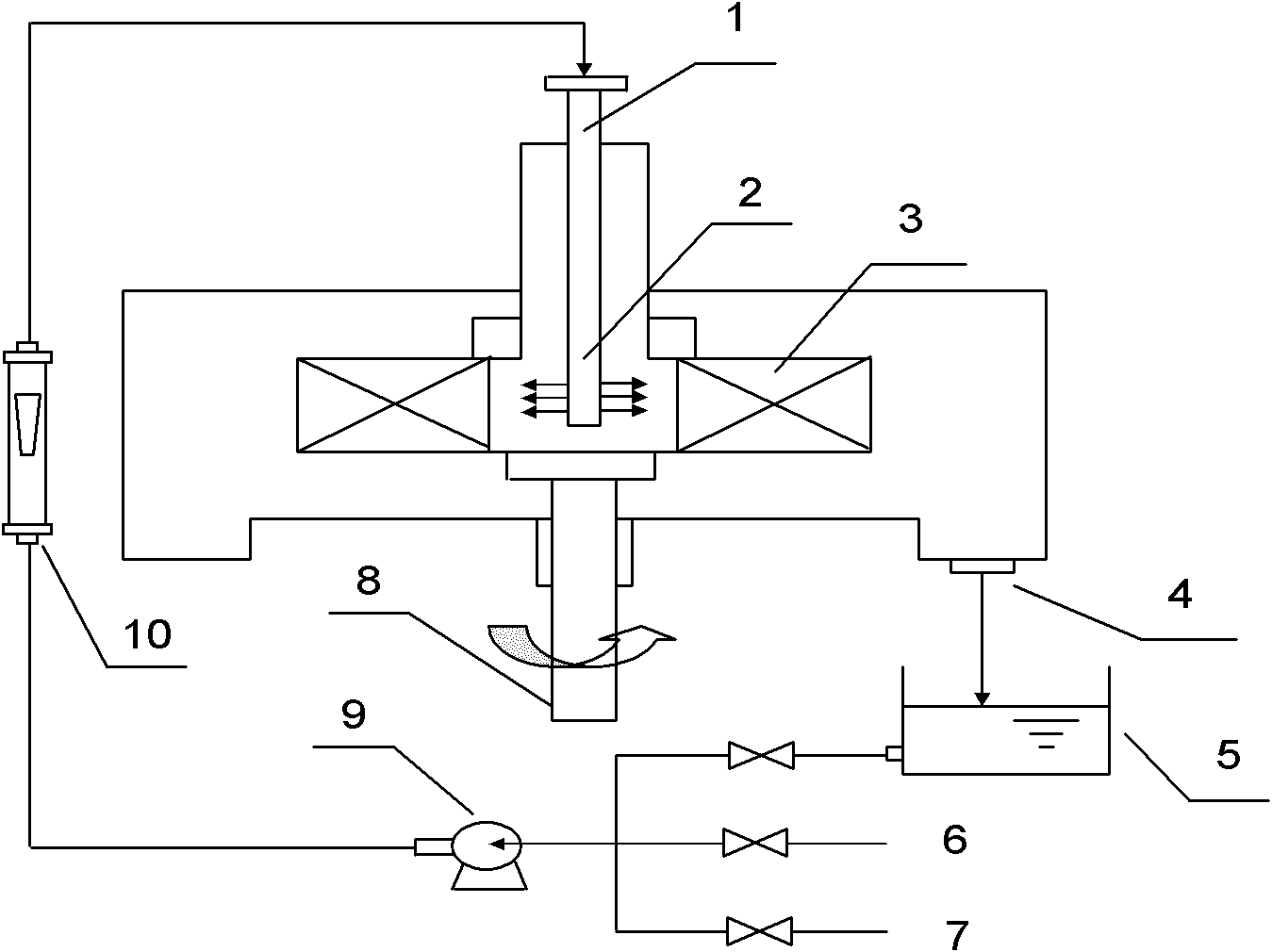

[0034] High-gravity-ion-exchange synthesis of nanocerium oxide, such as Figure 3-Figure 7 Shown:

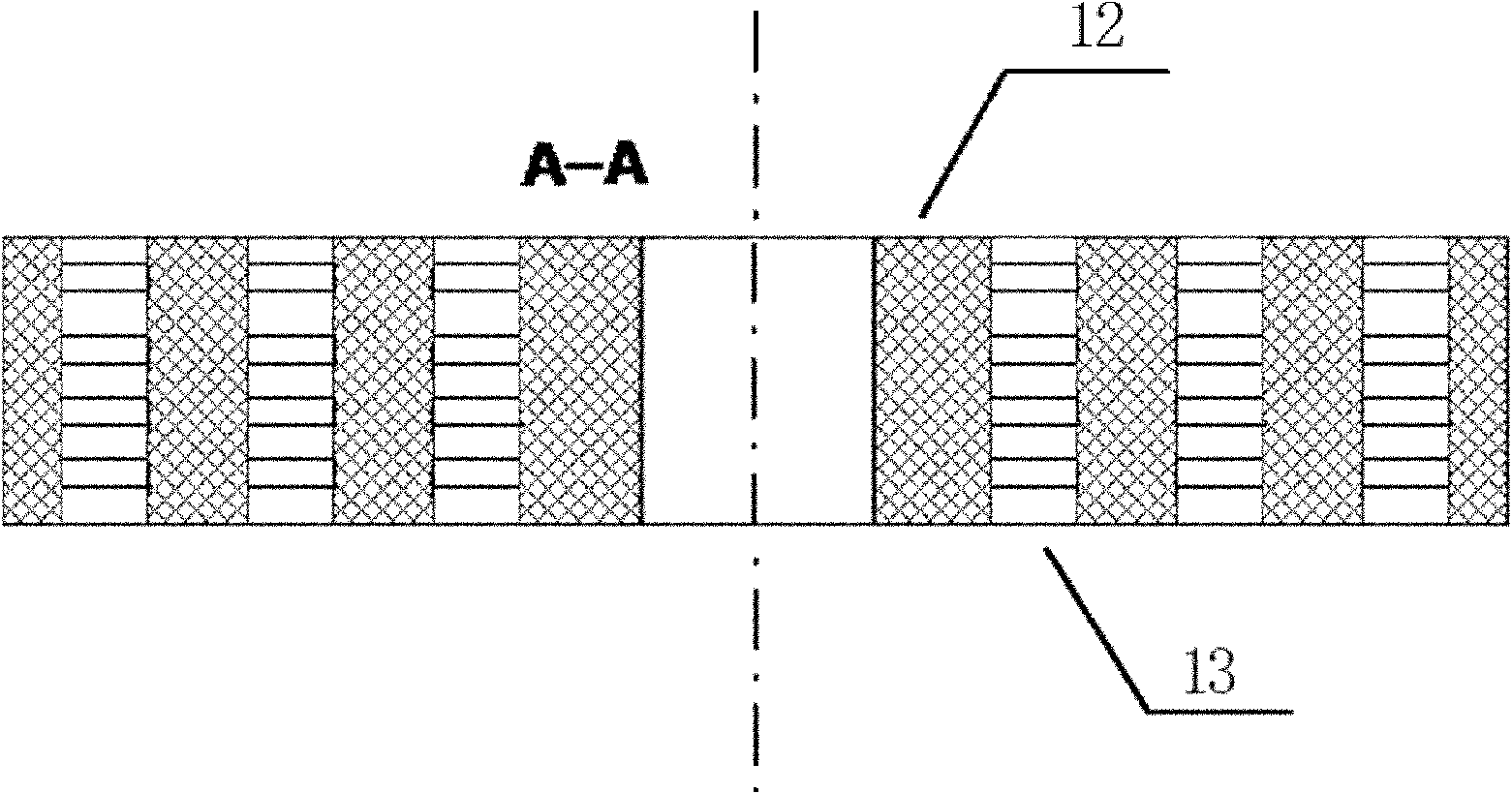

[0035] (1) The functional filler adopts polypropylene mesh-supported ion-exchange fiber composite filler.

[0036] (2) A certain amount of sodium hydroxide was dissolved in deionized water to prepare a 1.0mol / L solution, and the sample was injected from the spindle inlet of the supergravity-ion exchange reactor at a flow rate of 20ml / min, the reaction temperature was 20°C, and the spindle speed was 200r / min, the reaction solution was circulated for 30 minutes, switched to deionized water, washed with water at a flow rate of 20ml / min for 1 hour until the conductivity of the effluent was 100μs / cm, and the ion exchange fiber pre-exchange process was completed.

[0037] (3) Dissolve a certain amount of cerium nitrate in water to prepare a 0.1mol / L solution, switch the sample injection system that has completed the pre-exchange process to the cerium nitrate solution, the reaction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com