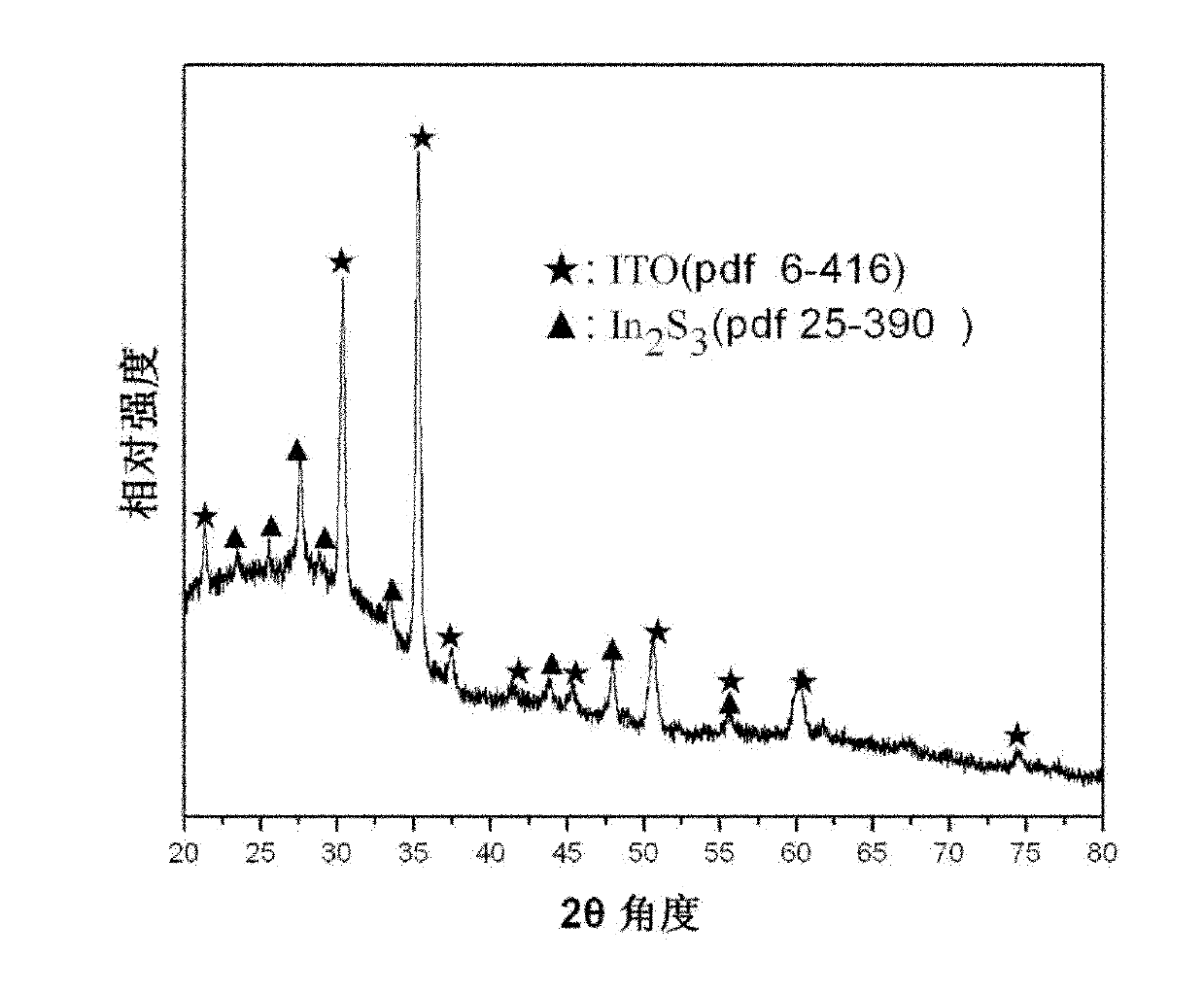

Solar cell device based on In2S3 netted nanocrystal array and P3HT hybrid film

A technology of solar cells and nanocrystals, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of harsh reaction conditions, unsatisfactory morphology, high substrate temperature, easy operation, avoid product impurity, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

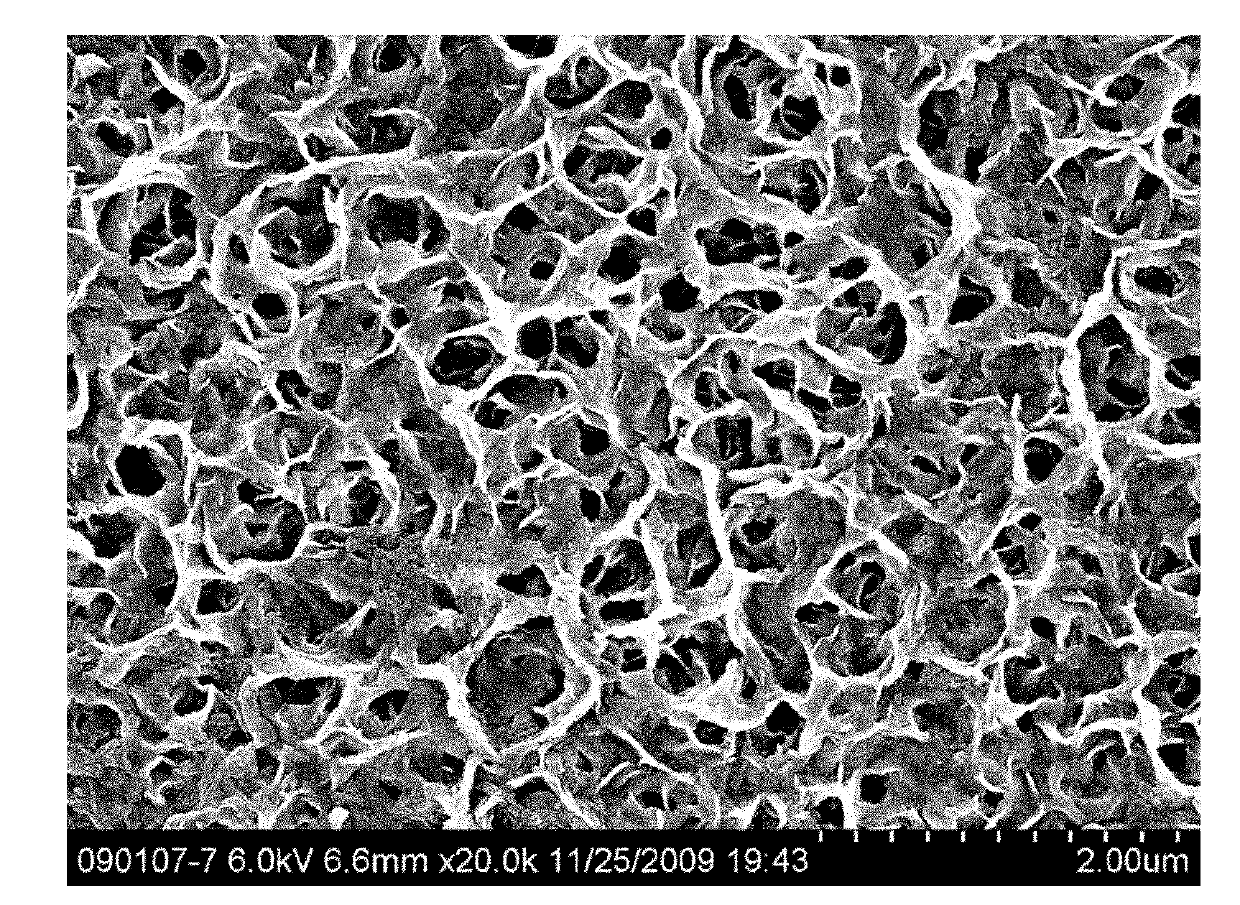

[0044] (1) Preparation: Clean the ITO glass twice with acetone ultrasonically (10 minutes / time), and then put it into NH 3 .H 2 O (25wt%), H 2 o 2 (30wt%) and H 2 The mixed solution of O was ultrasonically cleaned for 10 minutes, and its NH 3 .H 2 O:H 2 o 2 :H 2 The O volume ratio is 1:2:5, and then ultrasonically clean with isopropanol and deionized water for 5 minutes respectively. Finally, put the cleaned ITO glass into a vacuum drying oven to dry. Put the dried ITO glass into the ultraviolet ozone cleaner for 2 hours, then drop the filtered PEDOT:PSS (Baytron P 4083) on the ITO glass, and first rotate it at 500 rpm for 5 seconds. Then spin the film at 2500 rpm for 40 seconds. Put the spun PEDOT:PSS film into a vacuum drying oven, and dry it at 110°C for 40 minutes. Finally, put the ITO glass substrate spin-coated with a PEDOT:PSS film with a thickness of about 80 nm into a high-vacuum ion sputtering apparatus to sputter a layer of metal indium film with a thickn...

Embodiment 2

[0048] (1) preparatory work: with embodiment 1

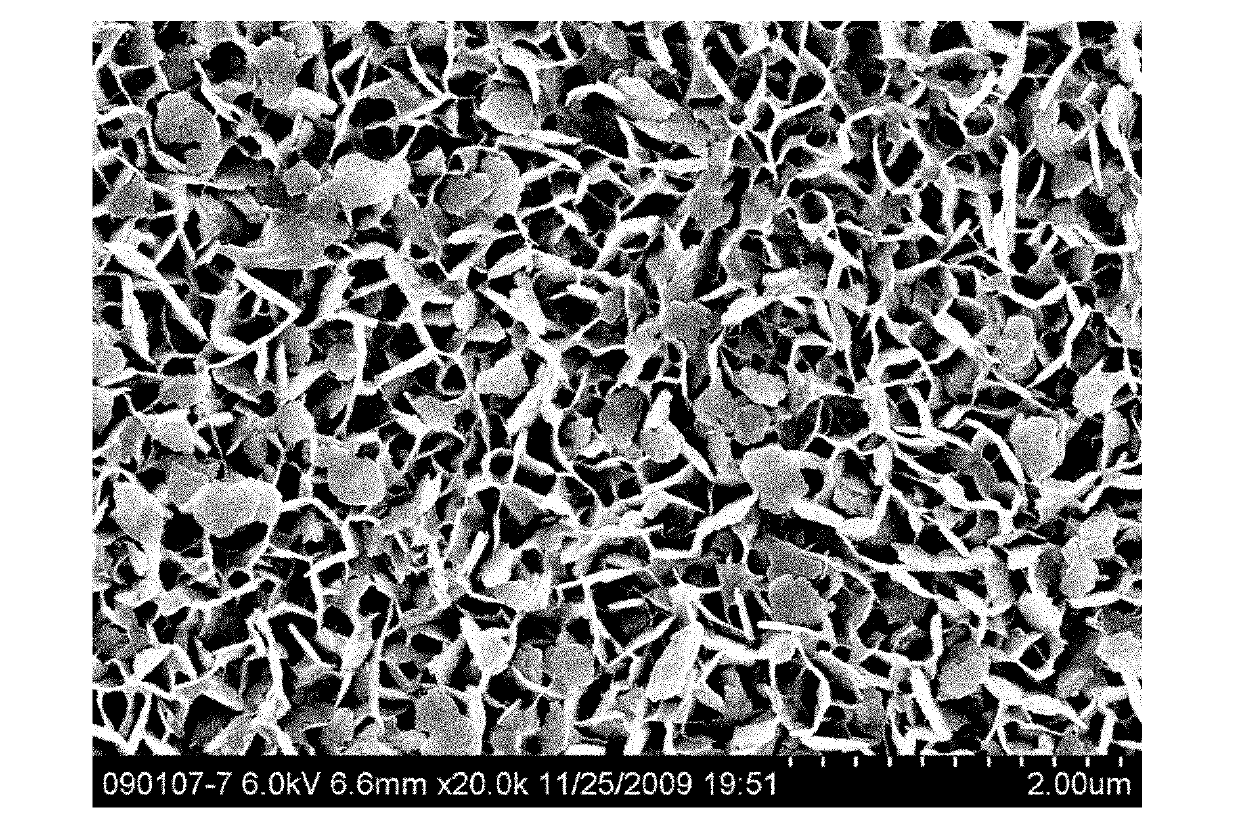

[0049] (2) Reaction step: put the ITO glass substrate that step (1) system has metal indium film (thickness is 30 nanometers) in the polytetrafluoroethylene liner of reactor, add sulfur powder, sulfur powder concentration is 0.0015 g / ml, then add anhydrous ethanol solvent to the height of 75% of the container, and at the same time put the polytetrafluoroethylene liner into the stainless steel jacket and place it in a constant temperature blast drying oven with a temperature-programming function, and raise the temperature to 180°C for reaction 24 hours.

[0050] (3) Post-processing: after the reaction, close the constant temperature blast drying oven and cool down to room temperature naturally. After washing the product with deionized water and absolute ethanol in sequence, the sample was dried in a vacuum drying oven at a constant temperature of 50° C. for 1 hour. Finally, the obtained indium sulfide film sample was carefully ...

Embodiment 3

[0052] (1) preparatory work: with embodiment 1

[0053](2) Reaction step: the ITO glass substrate that step (1) system has metal indium thin film (thickness is 40 nanometers) is put into the polytetrafluoroethylene liner of reactor, adds sulfur powder, and sulfur powder concentration is 0.001 g / ml, then add anhydrous ethanol solvent to the height of 75% of the container, and at the same time put the polytetrafluoroethylene liner into the stainless steel jacket and place it in a constant temperature blast drying oven with a temperature-programming function, and raise the temperature to 180°C for reaction 12 hours.

[0054] (3) Post-processing: after the reaction, close the constant temperature blast drying oven and cool down to room temperature naturally. After washing the product with deionized water and absolute ethanol in sequence, the sample was dried in a vacuum drying oven at a constant temperature of 50° C. for 1 hour. Finally, the obtained indium sulfide film sample w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com