Preparation method of core-shell magnetic conductive polymer microspheres and application thereof

A conductive polymer and polymer technology, applied in the direction of DNA preparation, recombinant DNA technology, etc., can solve the problems of increasing production costs and unfriendly environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

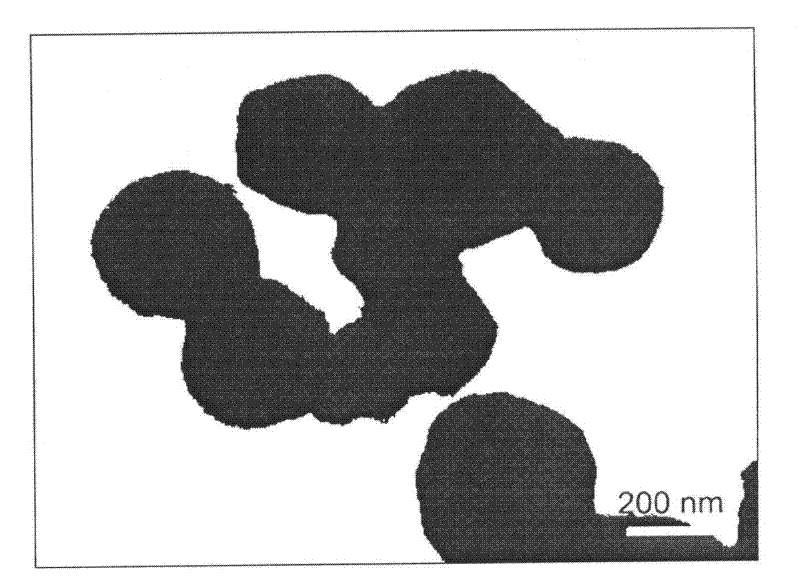

[0055] Example 1: Core-shell Fe 3 o 4 Preparation of / PANI composite microspheres

[0056] To a 100mL three-neck flask, add 0.1g Fe 3 o 4 , 40mL 0.1mol / L hydrochloric acid, ultrasonically dispersed at room temperature for 5min, sealed and placed in a 5°C thermostat for 12h, magnetic separation to remove the hydrochloric acid aqueous solution and retain the magnetic core; then add 15mL absolute ethanol, 0.1 g re-distilled aniline, ultrasonically dispersed for 5 minutes, and placed in a 5°C thermostat for 12 hours.

[0057] Place the flask in an ultrasonic cleaner, and control the water temperature of the ultrasonic cleaner to 5-10°C. Dissolve 0.25mL of 12mol / L hydrochloric acid in 45mL of distilled water, then add 0.28g of ammonium persulfate to dissolve, slowly add the oxidant solution dropwise, and control the dropping time to 0.5h; keep stirring for 3h under the assistance of ultrasound.

[0058] Magnetic separation of solid and liquid, washing with water for several ti...

Embodiment 2

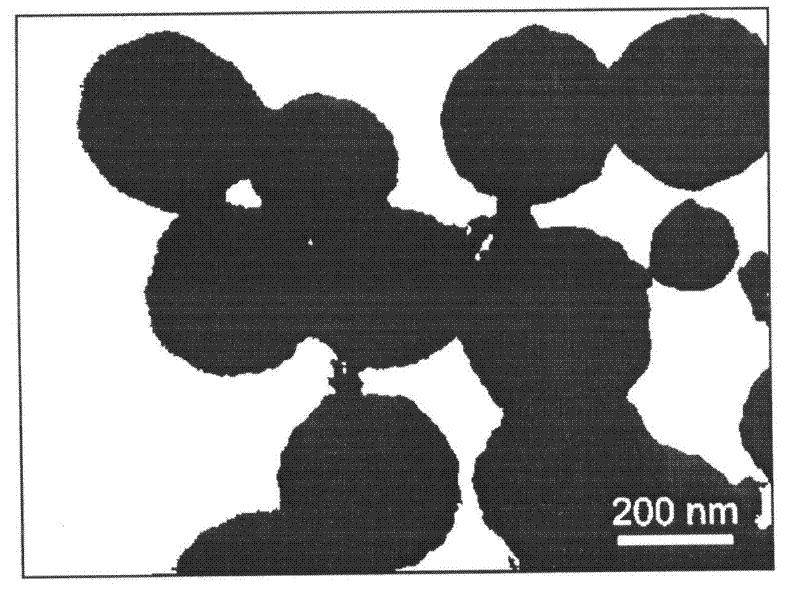

[0059] Example 2: Core-shell Fe 3 o 4 Preparation of / PPy composite microspheres

[0060] The aniline in embodiment 1 is replaced with pyrrole, and 0.28g ammonium persulfate is used 0.40g FeCl 3 ·6H 2 O is replaced, and other operations remain unchanged, and Fe can be obtained 3 o 4 / PPy samples.

Embodiment 3

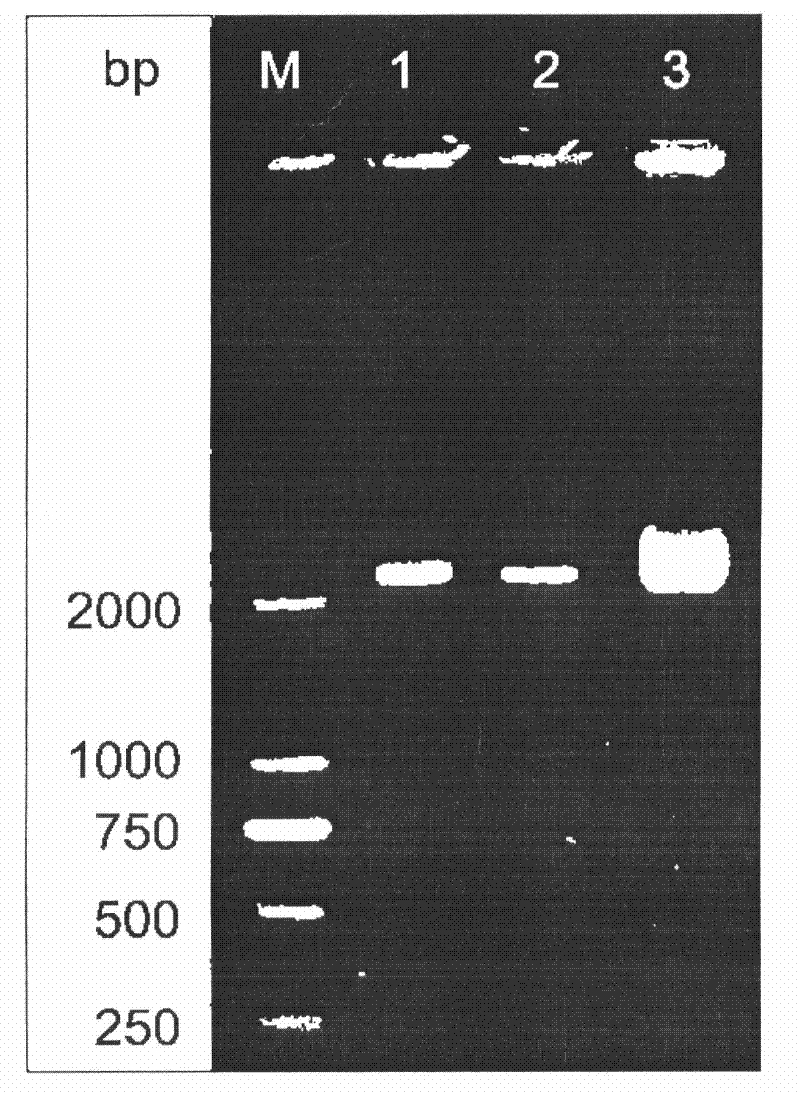

[0061] Embodiment 3: utilize Fe 3 o 4 / PANI Composite Microspheres Separation and Purification of Escherichia coli (E.coli DH5α) Plasmid DNA

[0062] Take 10mg of dedoped Fe 3 o 4 / PANI magnetic balls were placed in a 1.5mL sterile centrifuge tube, ultrasonicated and sterilized twice with 1mL 70% (v / v) ethanol solution, then transferred to another sterile centrifuge tube, and 40μL E.coli DH5α was added in sequence Plasmid DNA crude extract and 1mL Tris-HCl (10mmol / L, pH 7.8) buffer, shake well, place at room temperature for 20min until the DNA is adsorbed on the surface of the magnetic ball, collect the magnetic ball under a magnetic field, and discard the supernatant. The magnetic balls were washed twice with 1 mL of 70% ethanol solution, magnetically separated, the supernatant was discarded, and the magnetic balls that adsorbed DNA were placed at room temperature to volatilize the ethanol.

[0063] Add 0.4mL of 2mol / L NaCl solution to the centrifuge tube containing the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com