Polyether sulfone containing side group as well as preparation method and application thereof in gas separation membrane

A gas separation membrane, polyethersulfone technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation and other directions, can solve the problems of low permeability and unsatisfactory separation membrane performance, achieve high thermal stability, high The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

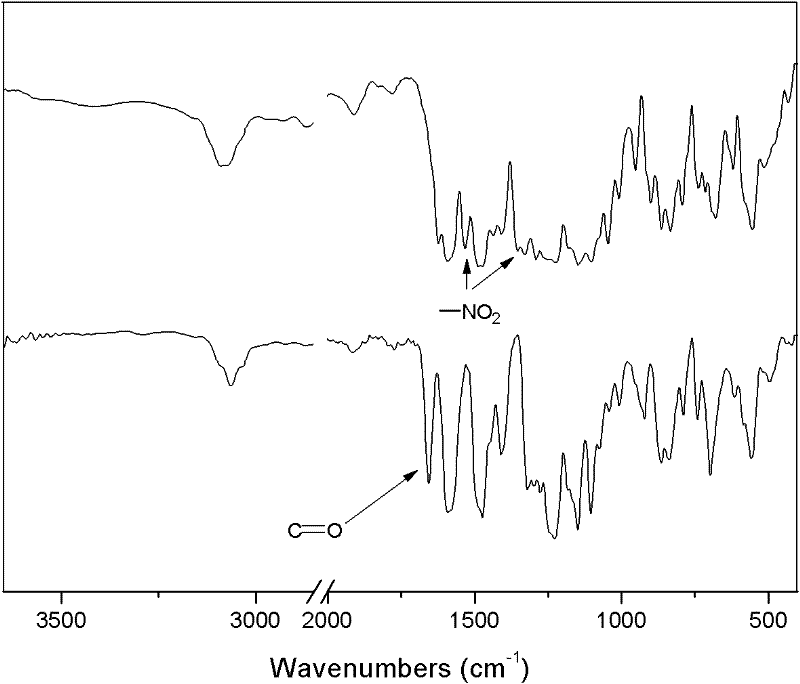

Method used

Image

Examples

Embodiment 1

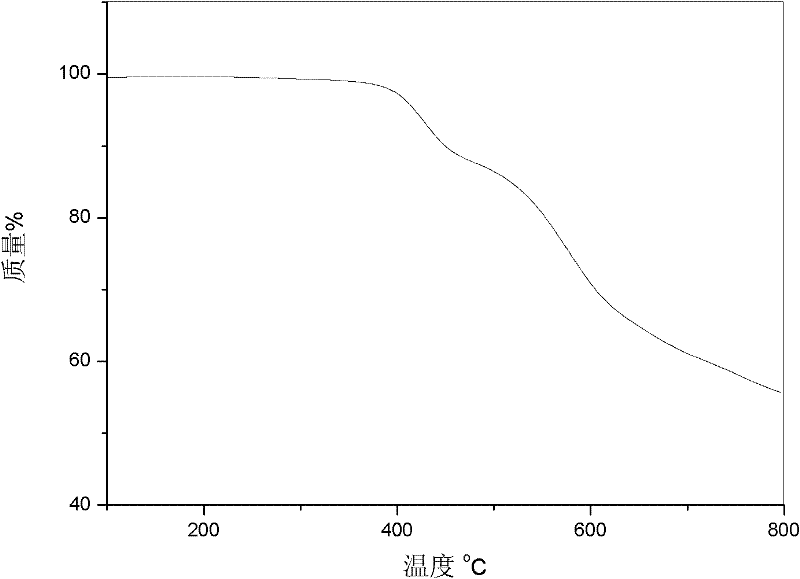

[0031] 10.8065g (0.05mol) of 3-methoxyphenylhydroquinone, 14.3580g (0.05mol) of 4,4'-dichlorodiphenylmethyl sulfone and 7.59g of anhydrous potassium carbonate, 100ml sulfolane, 40ml toluene Put it into a three-neck flask equipped with mechanical stirring and a water dispenser, raise the temperature to the reflux of the azeotropic dehydrating agent under the protection of nitrogen, react for 2.5 hours, remove toluene, and raise the temperature to 210-220°C to continue the reaction for 4 hours. The obtained polymer was precipitated in deionized water, pulverized, washed, and dried to obtain a white powder of polyethersulfone containing methoxy side groups. The glass transition temperature measured by DSC is 168°C, and the initial decomposition temperature measured by TGA is 452°C. The polymer structure is shown in the figure below:

[0032]

[0033] n=10-200.

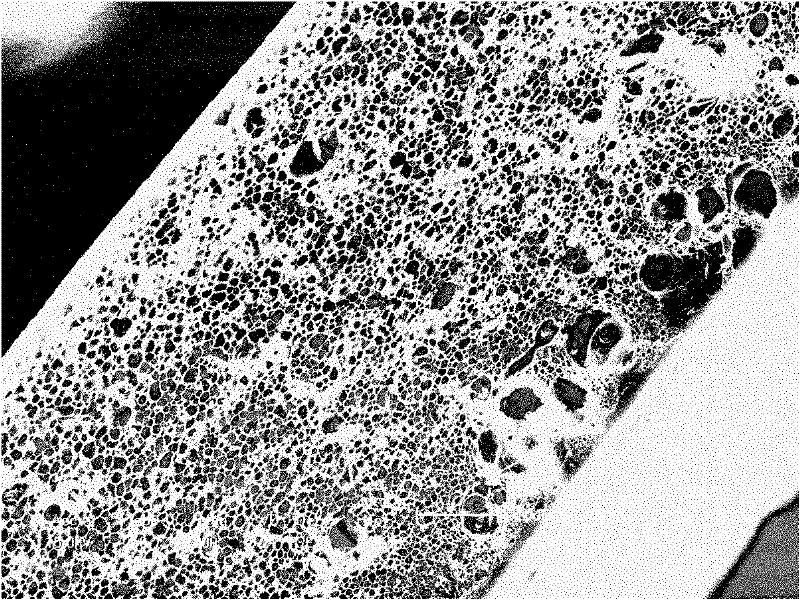

[0034] The polyethersulfone polymer containing methoxyl side groups is paved into a dense membrane, and the membra...

Embodiment 2

[0036] Add 15 g of polyethersulfone containing methoxy side groups prepared by the method in Example 1 into the pyridine hydrochloride solution prepared from 360 ml of pyridine and 400 ml of concentrated hydrochloric acid, and react at 170° C. for 12 hours under nitrogen protection. The obtained polymer was precipitated in a large amount of ice water, filtered, washed and dried. An off-white polyethersulfone powder containing hydroxyl side groups was obtained. The glass transition temperature is 209°C, and the initial decomposition temperature measured by TGA is 480°C. The structure is as follows:

[0037]

[0038] Wherein n=10~180.

[0039] The polyethersulfone polymer containing hydroxyl side groups is paved into a dense membrane, and the membrane permeability P(O 2 ) = 0barrer, P(N 2 )=0.015barrer, selectivity α(O 2 / N 2 )=0.

Embodiment 3

[0041] By the polyethersulfone 1g (2.4012mmol) that contains hydroxyl side group that makes in the embodiment 2, the anhydrous potassium carbonate of 0.1657g, 2.7079g (12.006mmol) 2-chloro-5-nitrobenzotrifluorotoluene, 25ml N , N-dimethylacetamide (DMAc), 15ml toluene is put into the 100ml there-necked bottle that is equipped with mechanical stirring and belt water device, is heated up to azeotropic dehydrating agent reflux under nitrogen protection, reacts for 2 hours, gets rid of azeotropic dehydrating agent , and the temperature was raised to 160° C. to continue the reaction for 4 hours. The obtained polymer was precipitated in de-ethanol, pulverized, washed, and dried to obtain a white polyethersulfone powder containing trifluoromethyl side groups. The glass transition temperature was 171°C as measured by DSC, and the initial decomposition temperature as measured by TGA was 420°C. The polymer structure is shown in the figure below:

[0042]

[0043] n=10-160.

[0044...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Initial decomposition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com