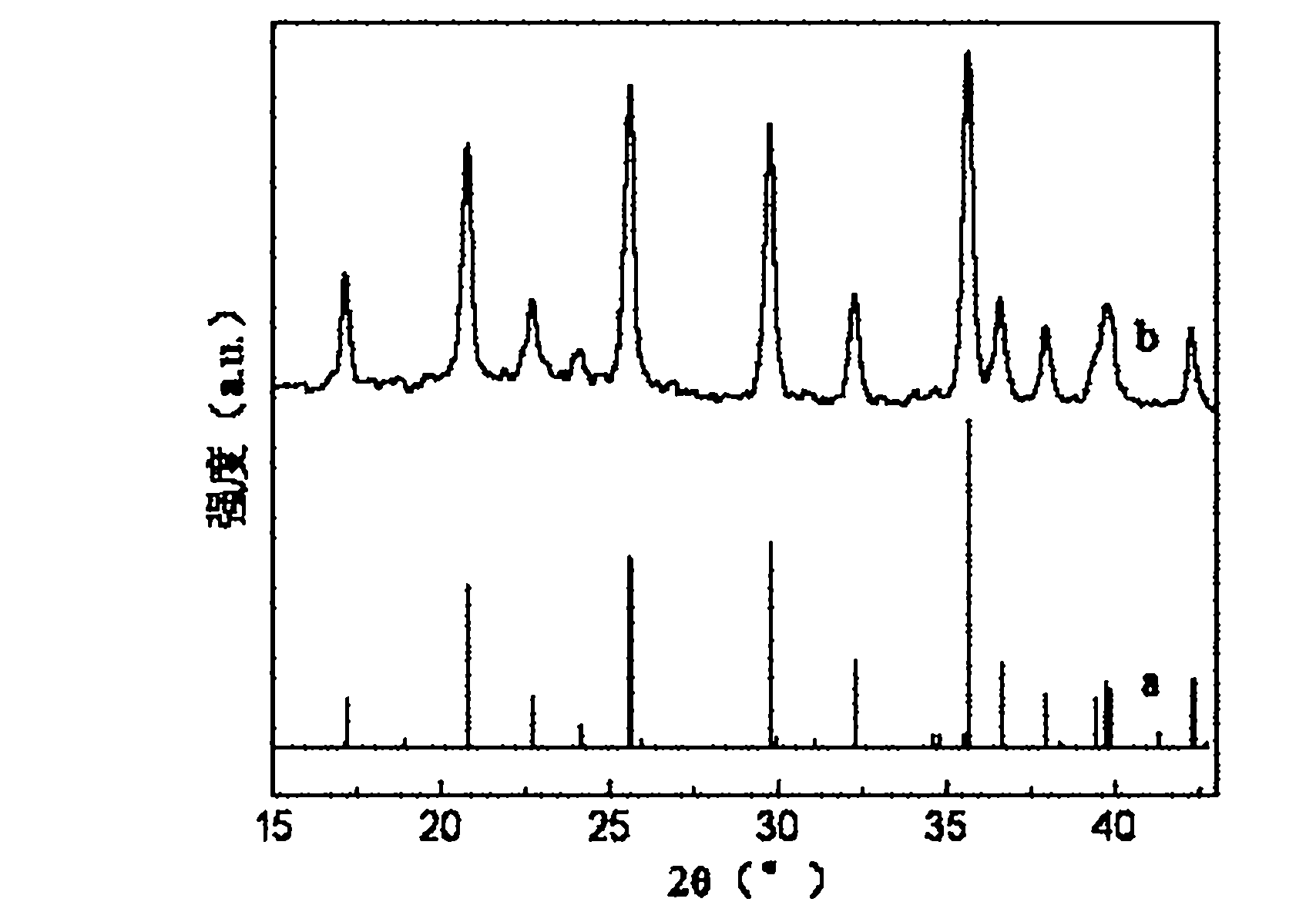

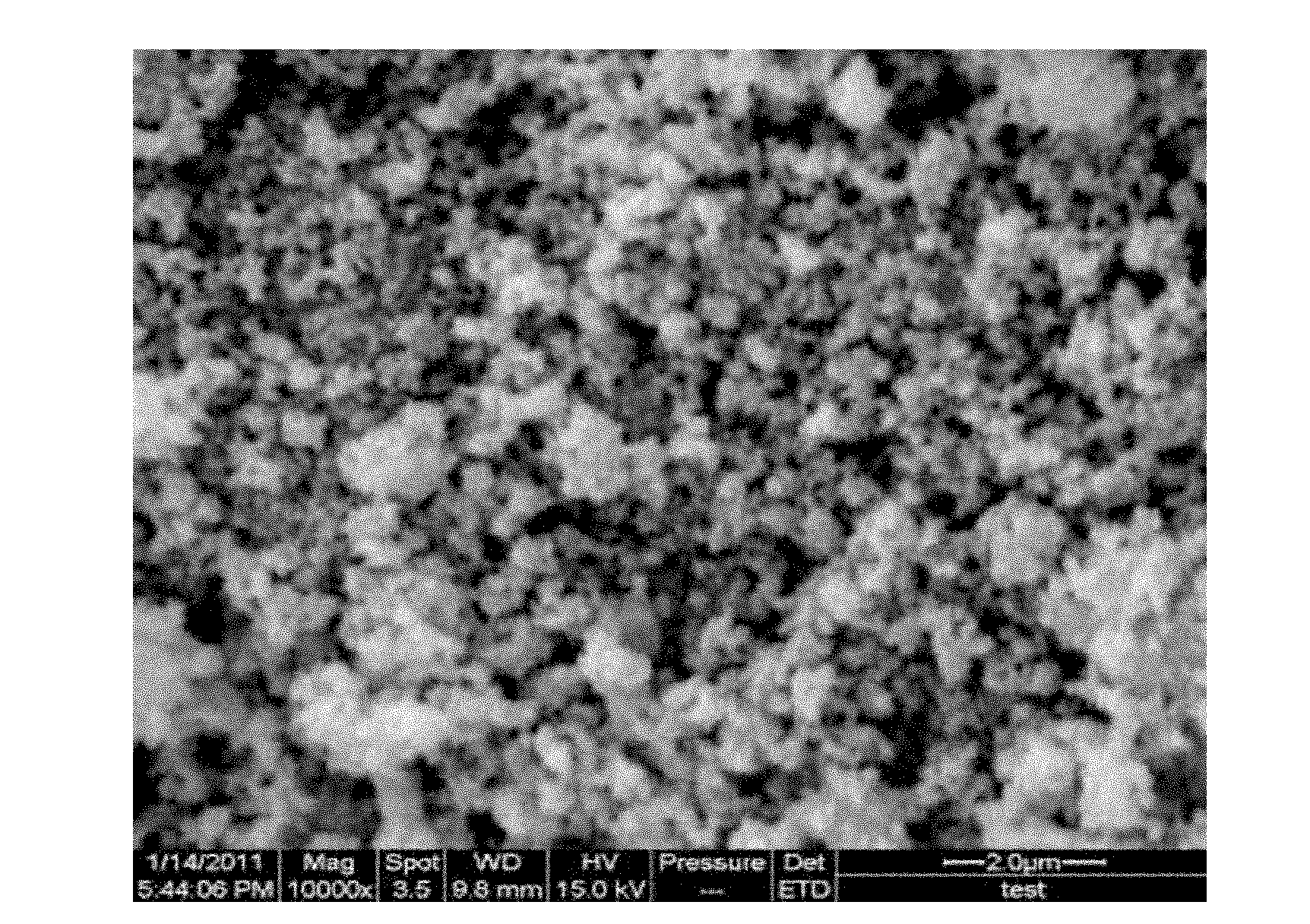

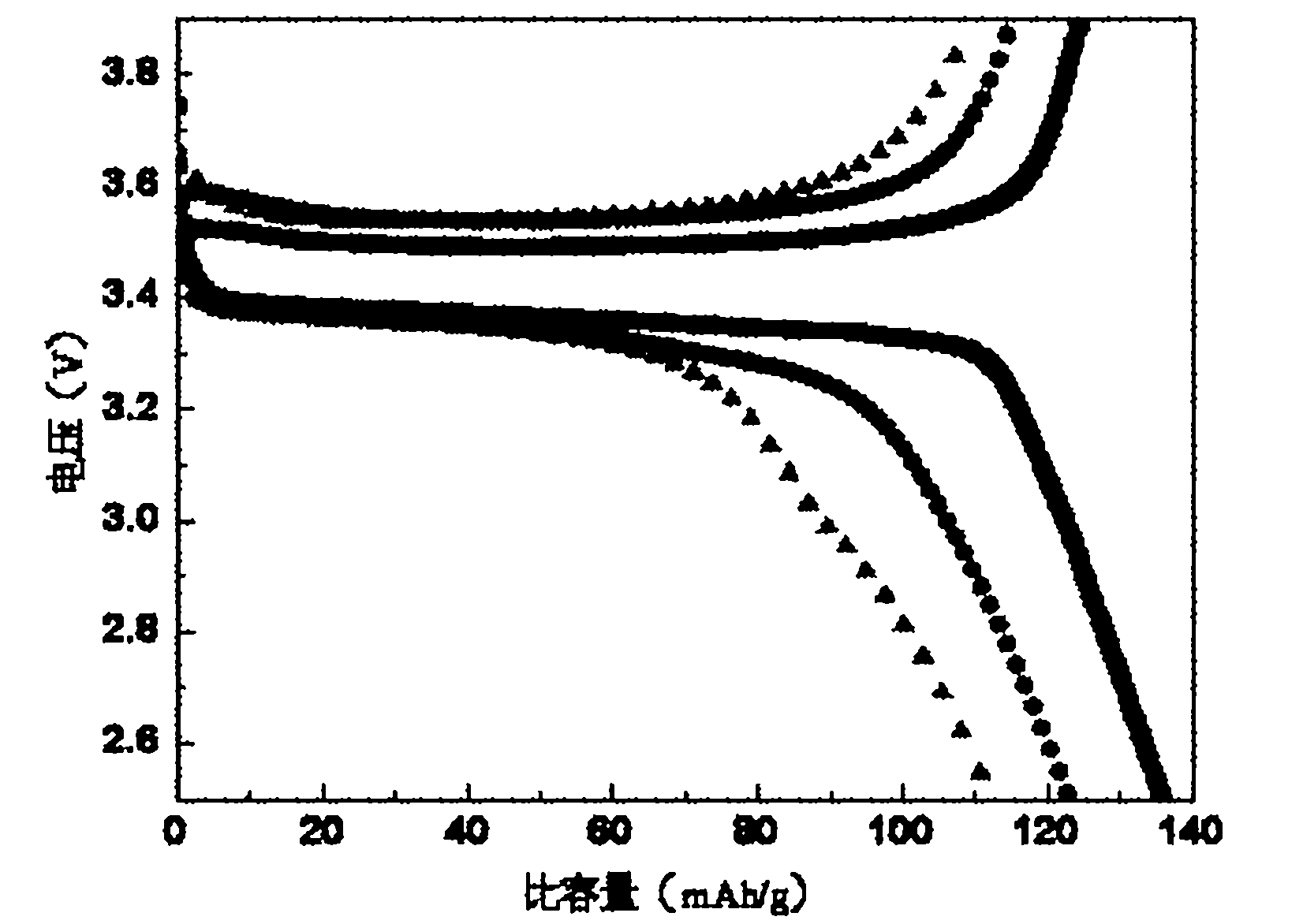

Method for synthesizing liquid phase of anode material LiFePO4/C powder of lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of easy oxidation of ferrous iron, achieve the effects of uniform particles, reduce energy consumption and oxidation, and simplify the experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific embodiment one: the liquid phase synthesis method of lithium iron phosphate lithium ion battery cathode material in the present embodiment is carried out according to the following steps:

[0014] 1. Weigh 0.2 mol of ferric nitrate and dissolve it in 200 mL of deionized water, add 0.1 mol of iron powder, and react in a closed container for 1-2 hours to obtain solution A;

[0015] 2. At room temperature, add the solution A obtained in step 1 into 0.3 mol of triphenyl phosphate, and add 0.3 mol to 0.36 mol of Li while stirring vigorously + and carbon source, the amount of carbon source added makes LiFePO 4 The carbon content in the / C powder is 5% to 15% (weight), and the mixture B is obtained;

[0016] 3. At room temperature and in an air atmosphere, use ammonia water to adjust the pH value of the mixture B obtained in step 2 to 2-3, and intermittently stir the reaction for 1-4 hours, and stir for 1 minute every 10 minutes; obtain the mixture C;

[0017] 4. Sp...

specific Embodiment approach 2

[0020] Specific embodiment two: the difference between this embodiment and specific embodiment one is that Li described in step two + Provided by lithium hydroxide solution, lithium acetate solution, lithium nitrate solution or lithium oxalate solution with a concentration of 1mol / L. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the carbon source described in step two is one of glucose, sucrose, polyethylene glycol, β-cyclodextrin, lauric acid and epoxy resin species or a mixture of them. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0022] In this embodiment, when the carbon source is a mixture, each carbon source is mixed in any ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com