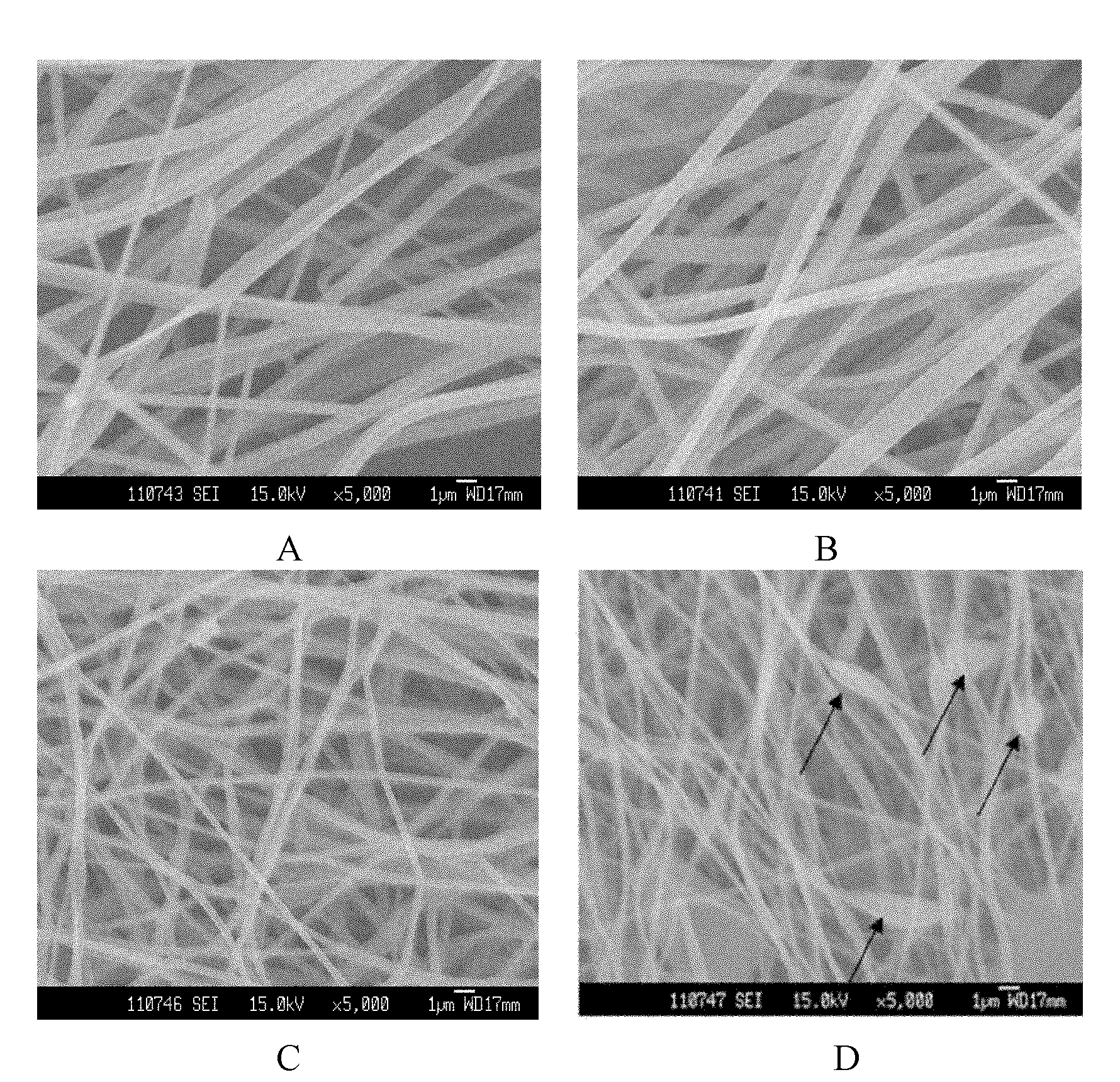

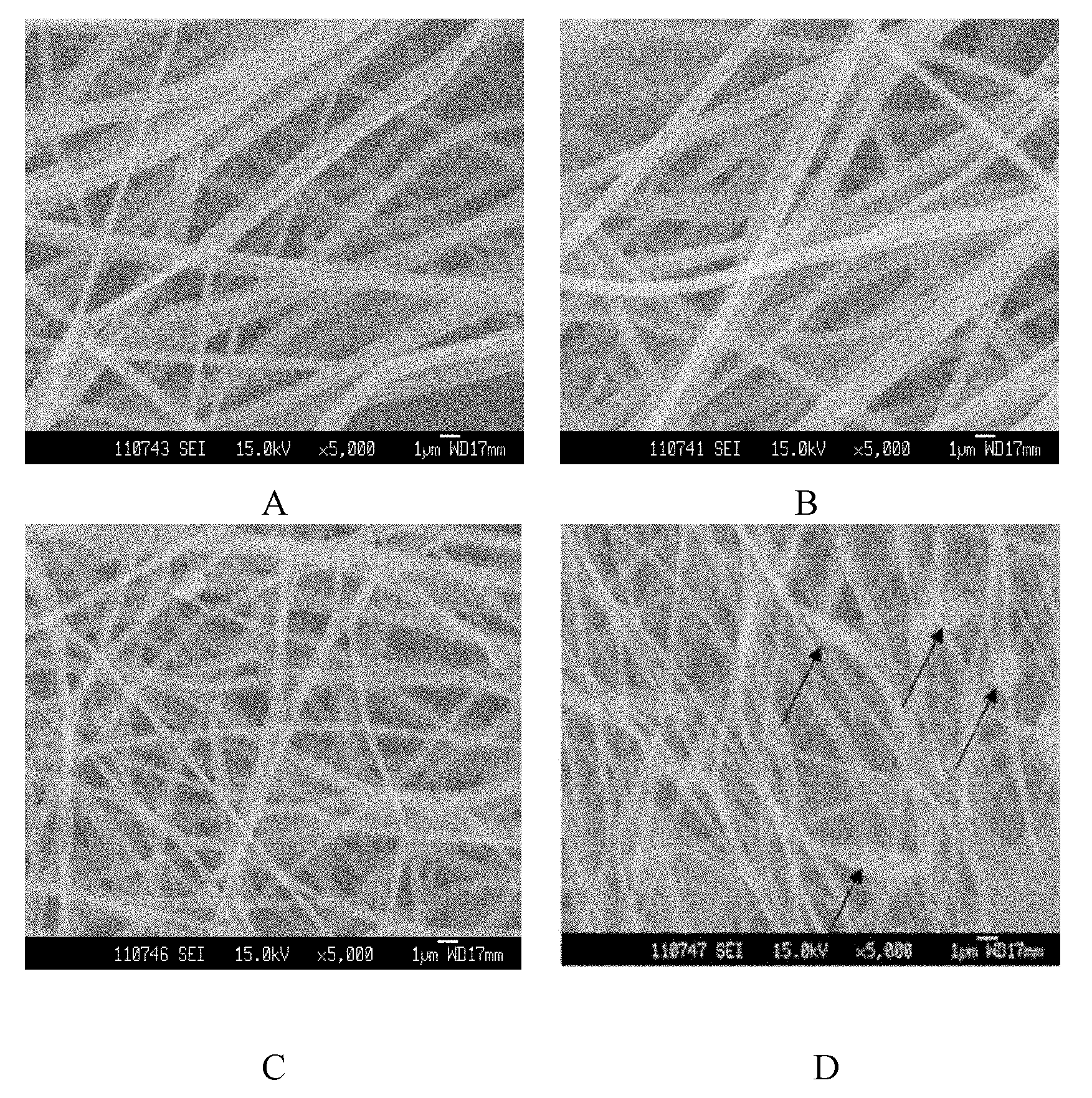

Method for loading hydrophobic medicament uniformly on hydrophilic polymer electrospinning nanofiber

A technology of electrospinning nanofibers and hydrophilic polymers, which is applied in the field of biomedical engineering and medicine, can solve problems such as uneven dispersion and easy aggregation into agglomerates, and achieve the effects of simple equipment, avoiding violent release, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

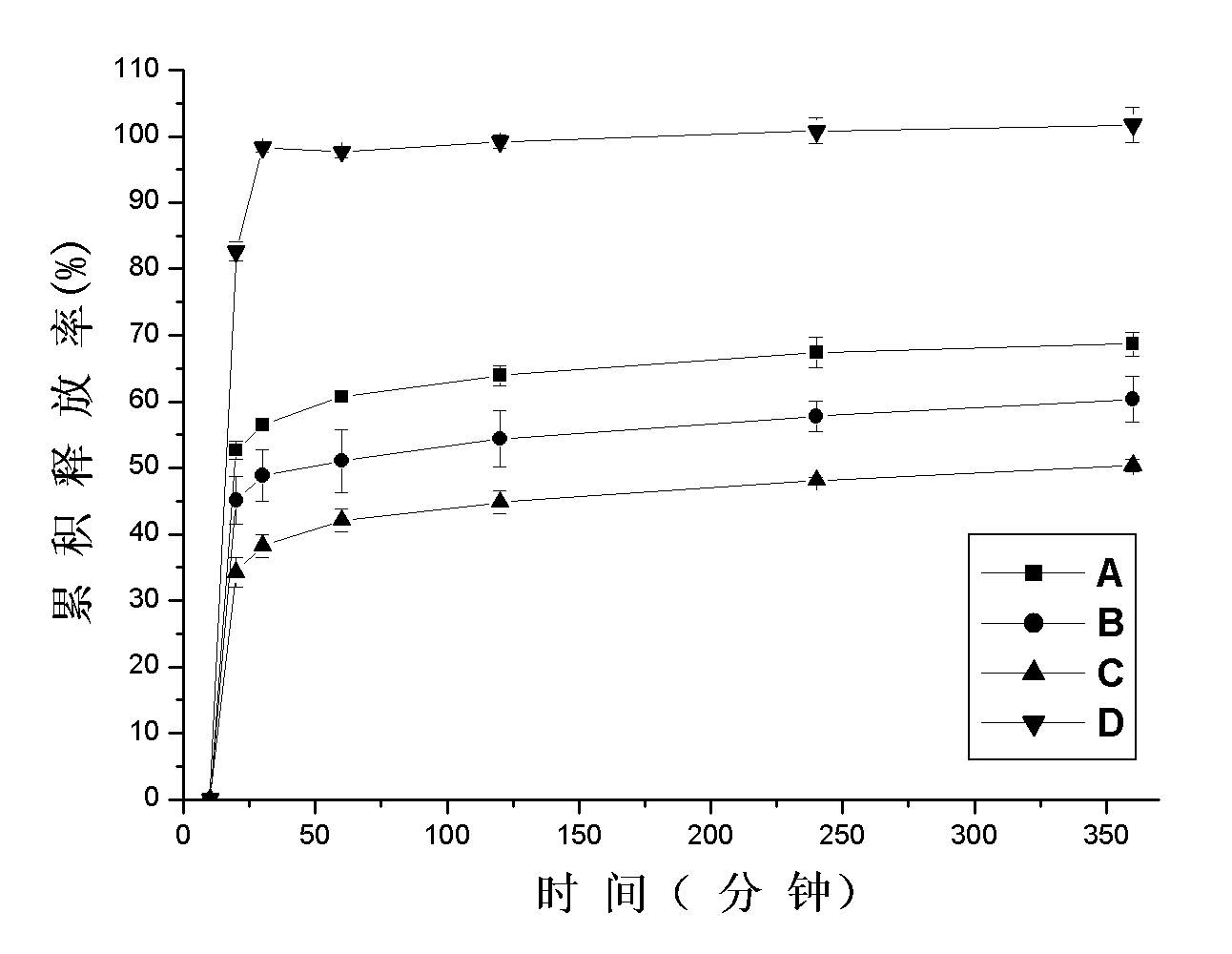

Embodiment 1

[0025] (1) Preparation of Hydrophobic Drug-β Cyclodextrin Inclusion Complex

[0026] The β-cyclodextrin is heated and dissolved in water at 60°C in a water bath to form a β-cyclodextrin aqueous solution with a mass concentration of 11.85%; the hydrophobic drug ibuprofen (Ibuprofen) is dissolved in ethanol to make a mass concentration It is 8.4% drug solution; slowly drop the drug solution into the β-cyclodextrin aqueous solution (the volume ratio of the β-cyclodextrin aqueous solution and the drug solution is 4:1), keep the water bath at 60°C after the dropwise addition, and use 400r Stir at a speed of 1 / min for 3 hours, pass the resulting solution through a 0.45 μm filter nanofiber, store the filtrate at 5°C overnight, filter it with suction, and dry it in vacuum at 40°C for 24 hours to obtain a hydrophobic drug-β-cyclodextrin inclusion compound thing;

[0027] (2) dissolving the hydrophobic drug-β-cyclodextrin inclusion complex obtained in step (1) in water to prepare a sol...

Embodiment 2

[0031] (1) Preparation of Hydrophobic Drug-β Cyclodextrin Inclusion Complex

[0032] Heat and dissolve β-cyclodextrin in water at 70°C in a water bath to form an aqueous solution of β-cyclodextrin with a mass concentration of 13%; dissolve the hydrophobic drug ibuprofen in ethanol to make a mass concentration of 9% drug solution; slowly drop the drug solution into the β-cyclodextrin aqueous solution (the volume ratio of the β-cyclodextrin aqueous solution and the drug solution is 4:1), keep the 60°C water bath after the dropping, and use 300r / min Stir at a high speed for 5 hours, pass the obtained solution through a 0.45 μm filter nanofiber, store the filtrate at 10°C overnight, filter it with suction, and dry it in vacuum at 60°C for 48 hours to obtain a hydrophobic drug-β-cyclodextrin inclusion compound;

[0033] (2) dissolving the hydrophobic drug-beta cyclodextrin inclusion complex obtained in step (1) in water to form a solution with a mass concentration of 2.0%;

[0034] ...

Embodiment 3

[0037] (1) Preparation of Hydrophobic Drug-β Cyclodextrin Inclusion Complex

[0038] Heat and dissolve β-cyclodextrin in water at 50°C in a water bath to form an aqueous solution of β-cyclodextrin with a mass concentration of 7%; take the hydrophobic drug ibuprofen and dissolve it in ethanol to make a mass concentration of 7% The drug solution; the drug solution is slowly dropped into the β-cyclodextrin aqueous solution (the volume ratio of the β-cyclodextrin aqueous solution and the drug solution is 4:1), and after the drop is completed, keep the water bath at 80 ° C, and use 300r / min Stir at a high speed for 6 hours, pass the obtained solution through a 0.45 μm filter nanofiber, store the filtrate at 4°C overnight, filter it with suction, and dry it in vacuum at 50°C for 32 hours to obtain a hydrophobic drug-β-cyclodextrin inclusion compound;

[0039] (2) dissolving the hydrophobic drug-β-cyclodextrin inclusion compound obtained in step (1) in water to prepare a solution wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com