Method for preparing ferulic acid and oligosaccharide by producing enzymes from Salicornia bigelovii straws fermented by Aureobasidium pullulans

A technology of Aureobasidium pullulans and ferulic acid, which is applied in biochemical equipment and methods, microorganism-based methods, fermentation, etc., can solve problems such as not much research, and achieve the effect of low land cost and low management cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

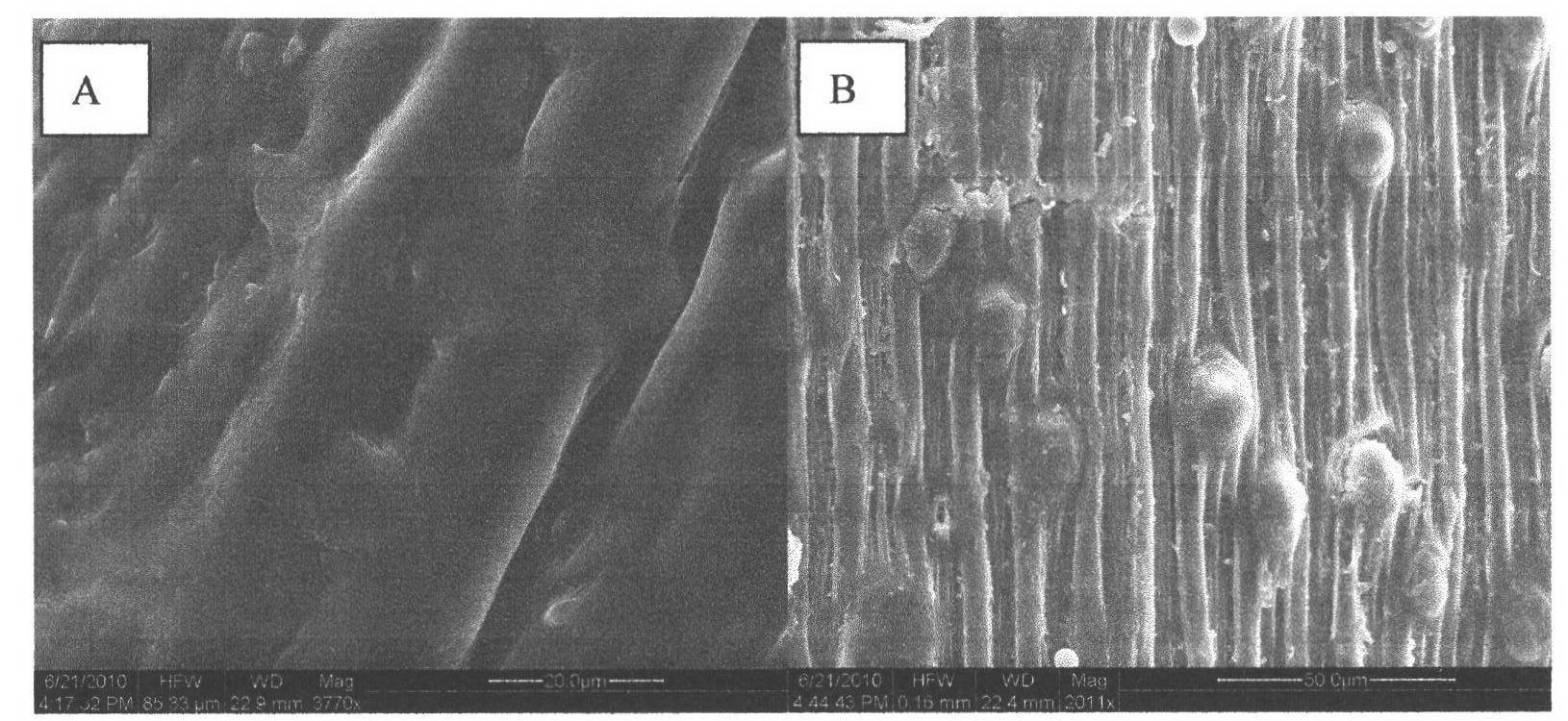

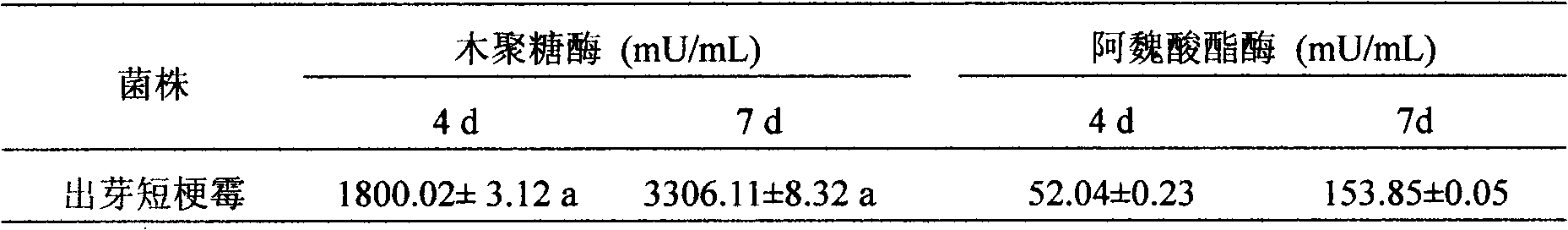

[0020] Example 1 Analysis of enzyme production effect of Aureobasidium pullulans metabolizing Salicornia stalks

[0021] Fermentation medium: 20-80g / L Salicornia stalk treatment liquid, add 0.05-0.3% KH 2 PO 4 and 0.05-0.4% MgSO 4 ·7H 2 O and 0.005~0.04% of V B1 ;

[0022] Preparation process of Salicornia straw treatment solution: After drying and crushing, the Salicornia straw is sieved through a 20-60 mesh sieve (20-80g / L) → adjust the pH to 4.5-6.0 with 1-5% sulfuric acid solution → 30-90 ℃ heat preservation for 2h → colloid mill treatment for 5-25min;

[0023] Sterilize with high pressure steam at 121°C for 15-20 minutes.

[0024] Cultivation of mother species: at a temperature of 25-30°C, a shaker speed of 80-160r / min, and a liquid volume of 20-100mL / 250mL triangular flask, inoculate 4 pieces of Aureobasidium pullulans with a diameter of about 6mm of the mother species block, cultivated for 5d;

[0025] Fermentation conditions: at a temperature of 25-30°C, a shak...

Embodiment 2

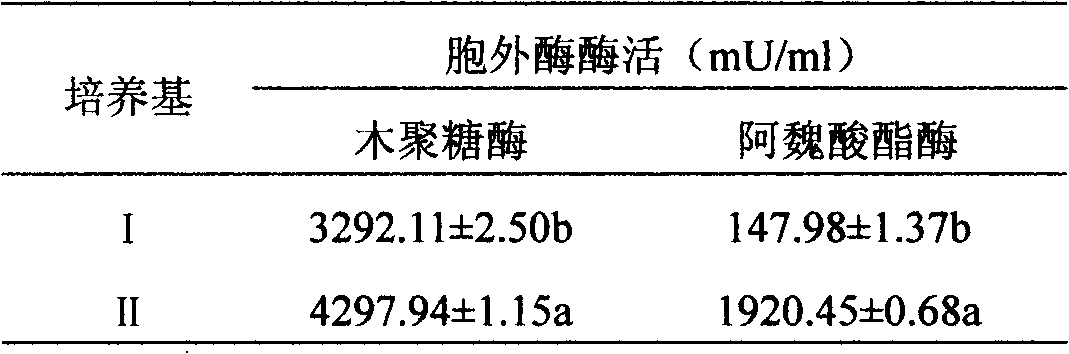

[0032] Example 2 Optimization of Aureobasidium pullulans Metabolism Salicornia stalk Enzyme Production Medium

[0033] Medium I Add V to the treatment solution of Salicornia stalks B1 0.05~0.4g / L, 0.50~4.0g / L MgSO 4 ·7H 2 O and potassium dihydrogen phosphate.

[0034] Medium II Add V to the treatment solution of Salicornia stalks B1 0.05~0.5g / L, MgSO 4 ·7H 2 O 0.50~5.0g / L and yeast extract 0.50~5.0g / L.

[0035] Fermentation conditions: at a temperature of 25-30°C, a shaker speed of 80-160r / min, a liquid volume of 20-100mL / 250mL Erlenmeyer flask, an Aureobasidium pullulans inoculum of 2-10%, and culture for 4-10 days.

[0036] Effect of culture medium on enzyme production of Aureobasidium pullulans

[0037] It can be seen from Table 2 that the enzyme production by the fungus was significantly different when the tea salamander was fermented in different media. In the optimized medium composition, the activities of extracellular xylanase and ferulic esterase produced by A...

Embodiment 3

[0041] Example 3 Optimization of Fermentation Conditions for Aureobasidium pullulans Metabolism Salicornia stalk Enzyme Production

[0042] Fermentation condition I pH5.0, liquid volume 50mL and inoculum volume 6%.

[0043] Fermentation condition II pH5.5, liquid loading volume 60mL and inoculum volume 12%, fermentation temperature is 25 ℃.

[0044] Fermentation medium wheat bran treatment liquid added V B1 0.14g / L, MgSO 4 ·7H 2 O 1.10g / L and yeast extract 2.50g / L. Effects of Fermentation Conditions on the Enzyme Production of Aureobasidium pullulans

[0045] Table 3 Fermentation of Aureobasidium pullulans to produce enzymes under different conditions

[0046] Table 3 Enzymes and activities pullulan during fermentation in different conditions

[0047]

[0048] From the enzyme production of Aureobasidium pullulans under different fermentation conditions (Table 3), it can be seen that culturing under optimized fermentation conditions can change the extracellular enzyme ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com