Fluorescent material with molybdate and tungstate as matrixes as well as preparation method and application thereof

A fluorescent material, molybdenum tungstate technology, applied in the direction of luminescent materials, chemical instruments and methods, the use of gas discharge lamps, etc., can solve the problems of cumbersome production process, complex chemical composition, etc. High, simple method and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

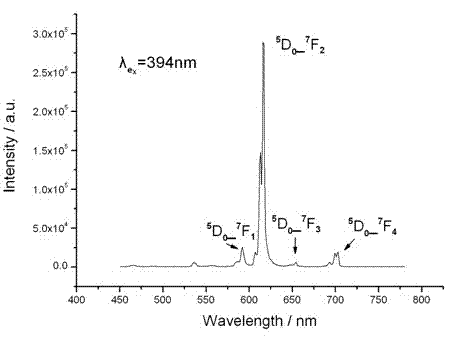

Embodiment 1

[0029] (1) In accordance with 0.1Eu 3+ :Na 5 Y 0.9 (WO 4 ) 2 (MoO 4 ) 2 The molar ratio represented by the chemical formula uses the electronic balance to weigh Na respectively 2 MoO 4 2H 2 O. WO 3 , Y 2 o 3 、MoO 3 、Na 2 CO 3 、Eu 2 o 3 Raw materials (the purity of each chemical component is above 99.99%), the following reaction formula is used for batching:

[0030] 2Na 2 CO 3 + 3Na 2 MoO 4 2H 2 O +4WO 3 +0.1Eu 2 o 3 +0.9Y 2 o 3 +MoO 3

[0031] →2Eu 3+ :Na 5 Y 0.9 (WO 4 ) 2 (MoO 4 ) 2 +2CO 2 ↑+6H 2 o

[0032] (2) Fully grind the above-mentioned weighed raw materials in a corundum mortar for more than half an hour until they are evenly mixed, then put them into a platinum crucible, and place them in a high-temperature heating furnace for heating, and use a temperature controller to set the heating program. The heating temperature program is to increase the temperature from room temperature to 600°C at a rate of about 70°C / hour, and sinter...

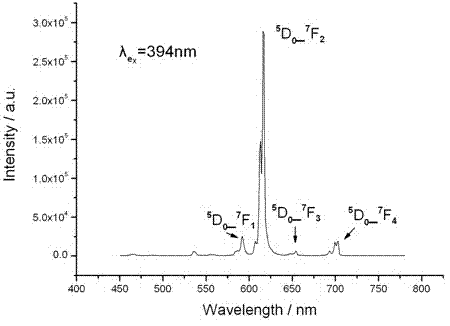

Embodiment 2

[0035] (1) In accordance with 0.5Eu 3+ :Na 5 Y 0.5 (WO 4 ) 2 (MoO 4 ) 2 The molar ratio represented by the chemical formula uses the electronic balance to weigh Na respectively 2 MoO 4 2H 2 O. WO 3 , Y 2 o 3 、MoO 3 、Na 2 CO 3 、Eu 2 o 3 The raw material adopts the reaction formula similar to Example 1 to carry out during batching

[0036] (2) Put the above-mentioned weighed raw materials in a corundum mortar, grind them, mix them uniformly, put them into a crucible, and heat them in a high-temperature heating furnace according to Example 1, and use a temperature controller to set the temperature rise program. The heating temperature program is to increase the temperature from room temperature to 630°C at a rate of 75°C / hour, and sinter at this temperature for 7 hours, then cool down to 190°C at a rate of about 65°C / hour and then stop the heating equipment , and finally let the material cool down to room temperature and take it out.

[0037] (3) Grind the take...

Embodiment 3

[0039] (1) In accordance with 0.8Eu 3+ :Na 5 Y 0.2 (WO 4 ) 2 (MoO 4 ) 2 The molar ratio represented by the chemical formula uses the electronic balance to weigh Na respectively 2 MoO 4 2H 2 O. WO 3 , Y 2 o 3 、MoO 3 、Na 2 CO 3 、Eu 2 o 3 The raw material, batching method is similar to embodiment 1 and embodiment 2.

[0040] (2) The processing steps and methods of the weighed raw materials are the same as in Example 1 and Example 2. The heating temperature program is to rise to 650 °C at a heating rate of about 80 °C / hour, and sinter at this temperature for 8 hours at a constant temperature, and then After cooling down to 200°C at a cooling rate of 70°C / hour, stop the heating equipment, and finally allow the material to cool naturally to room temperature before taking it out.

[0041] (3) Grind the taken out sample again in a corundum mortar, and then put the sample into a 250-mesh sieve for sieving treatment to obtain the europium-doped sodium yttrium tetramoly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com