Catalytic cracking catalyst and preparation method thereof

A catalytic thermal cracking and catalyst technology, which is applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as unsatisfactory effects, and achieve good anti-calcium pollution performance, good sphericity, and high ethylene yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] (1) 17.0Kg halloysite (industrial product of Suzhou China Clay Company, solid content 72.3% by weight) was roasted at 800° C. for 1.5 hours, then mixed with 48.0 Kg decationized water, beating to obtain kaolin slurry;

[0032] (2) 20Kg decationized water is mixed with 11.9Kg pseudo-boehmite (industrial product of Shandong Aluminum Plant, solid content 63m%), beating, and its pH value is adjusted to 3 with hydrochloric acid;

[0033] (3) 5.19Kg of ZrOCl 2 (where ZrO 2 Content is 36% by weight, technical grade, product of Zibo Huantuo Chemical Co., Ltd.) and deionized water are mixed to prepare ZrOCl 2 Concentration is the solution of 1.0mol / L, add ammoniacal liquor (Beijing Chemical Plant, concentration 25% by weight) under stirring to pH value 9, then aged 26 hours at 25 ℃, under stirring, filter to get ZrO(OH) 2 Gel, washed with deionized water until no Cl was detected in the washing solution after washing - , dried at 120°C for 24 hours, and calcined at 550°C for 2...

example 2

[0040] (1) Get 11.4Kg hallowed kaolin (industrial product of Suzhou China Clay Company, solid content 72.3% by weight) and roast at 700°C for 2 hours, mix with 48.0Kg decationized water, beating, and make kaolin slurry.

[0041] (2) 20Kg decationized water is mixed with 11.9Kg pseudo-boehmite (industrial product of Shandong Aluminum Plant, solid content 63m%), beating, and its pH value is adjusted to 2.5 with hydrochloric acid;

[0042] (3) 6.87Kg zirconium oxychloride (zirconia content is 36% by weight, industrial grade, Zibo Huantuo Chemical Co., Ltd.) is mixed with deionized water to make ZrOCl 2 A solution with a concentration of 1.5 mol / L, under stirring, was added ammonia water (Beijing Chemical Plant, 25% by weight) to a pH value of 10, then aged at 30°C for 16 hours with stirring, and filtered to obtain ZrO(OH) 2 Gel, washed with deionized water until Cl-free in the washed water - Detected, dried at 115°C for 26 hours, and calcined at 600°C for 5 hours to obtain 2.47 ...

Embodiment 3~4

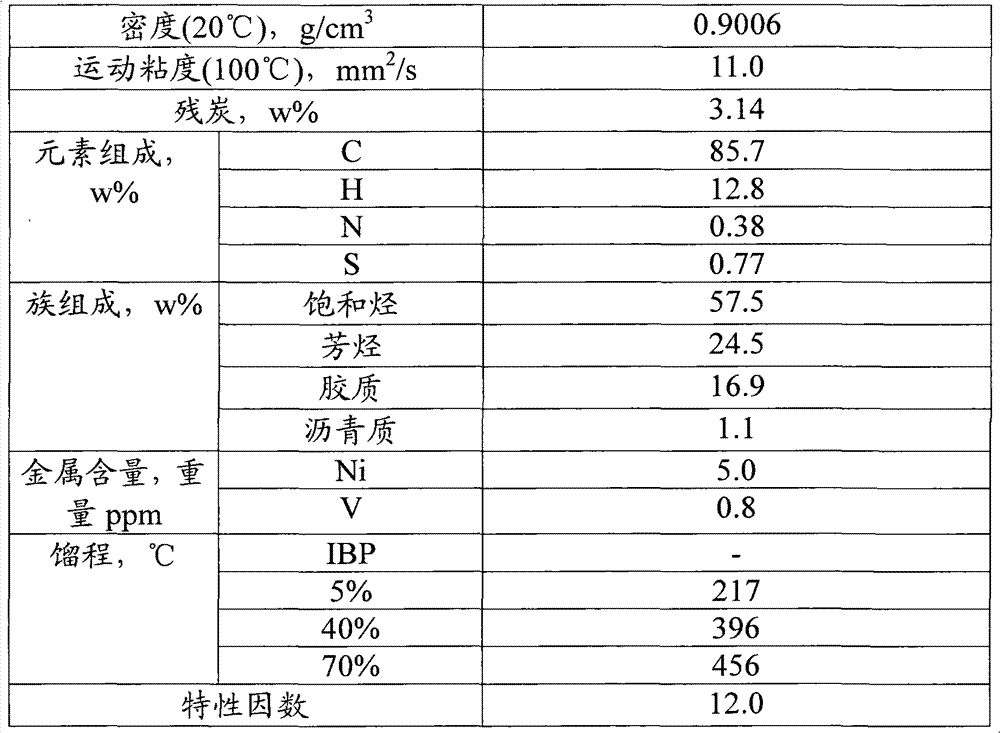

[0054] On a small-scale fixed fluidized bed device, take 30m% residual oil + 70m% wax oil (see Table 2 for properties) as raw material, and add iron naphthenate to it, so that 0.5% by mass of iron is contained in the raw material oil, and the catalyst sample A~B were evaluated, the reaction temperature was 640°C, the weight ratio of agent to oil was 15, the mass ratio of water to oil was 35:1, and the weight hourly space velocity was 10h -1 . The catalyst sample was treated with 100% steam at 800°C for 17 hours in advance, and the loading amount was 240 grams. The evaluation results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com