Epitaxial structure of LED (light-emitting diode) with GaN (gallium nitride)-based vertical structure and manufacturing method thereof

An epitaxial structure and vertical structure technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as poor heat dissipation effect, stress damage, current congestion, etc., achieve low equipment requirements, achieve low cost, solve the problem of current congestion and Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

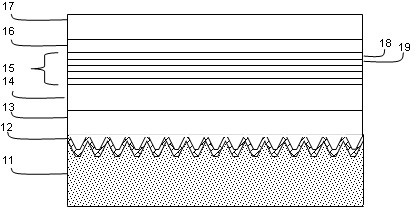

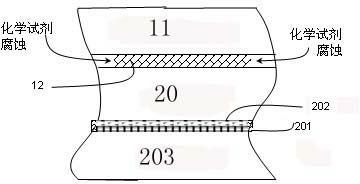

[0035] (1) Firstly, the ZnO buffer layer 12 is prepared on the epitaxial growth substrate 11, and the substrate: a patterned sapphire substrate is selected. see figure 2 , using a ZnO buffer growth structure on a patterned sapphire substrate see figure 2 . Define the pattern on the substrate by means of photolithography or mask, and form a submicron to several micron periodic surface convex-concave microstructure by wet etching or dry etching. The side of the microstructure is a quasi-nonpolar crystal plane or Non-polar crystal planes can also be curved. The molecular layer structure of ZnO is deposited on this substrate, and the deposition tool can be laser-assisted molecular beam epitaxy, laser sputtering, or oxide vapor phase epitaxy. The deposited ZnO film can be amorphous, polycrystalline, or single crystal. The thickness of ZnO is controlled at 0.1 micron to 100 micron.

[0036] (2) Continue to grow the extrinsically doped GaN buffer layer 13 on the grown ZnO thin f...

Embodiment 2

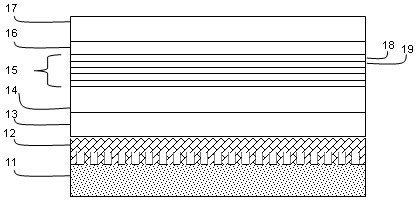

[0041] (1) Firstly, a ZnO buffer layer 12 is prepared on the epitaxial growth substrate 11, and the substrate: a planar sapphire substrate is selected. see figure 1 , first in the ZnO epitaxial technology using a three-dimensional preferential growth mode for self-organized growth, forming a high-density columnar ZnO nanowire structure with a diameter of several nanometers to submicrons on the substrate. The height of the nanowires is comparable to the pitch of the pillars. Then switch to the mode of lateral growth priority, grow a ZnO film with a thickness of 1 micron to 10 microns until the surface is flat, and all columnar ZnO structures are completely filled.

[0042] (2) Continue to grow the extrinsically doped GaN buffer layer 13 on the grown ZnO thin film substrate in metal organic vapor phase epitaxy (MOCVD) equipment. Firstly, the temperature of the reaction chamber is controlled below 500° C. to grow the low-temperature GaN buffer layer 13 , and at the same time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com