Production method of liquid phagostimulant for fattening pigs

A production method and a technology for attracting food, which are applied in the field of feed additives, can solve the problems of adverse effects on the palatability of feeds, affecting the total amount of nutrients ingested, poor palatability of feeds, etc. The effect of high feed intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

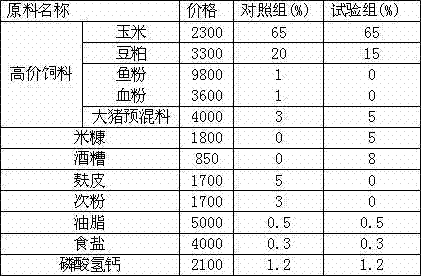

Image

Examples

Embodiment 1

[0022] Step 1.1: Prepare Saccharomyces boulardii test-tube slant medium and Streptococcus lactis test-tube slant medium respectively: 1wt% of yeast extract, 2wt% of tryptone, 2wt% of glucose, 2wt% of agar powder and the rest of distilled water in proportion Mix and prepare a 1000ml solution, sterilize at 121°C for 15 minutes, place on a slant, incubate at 37°C for 24 hours, and perform a sterility test to obtain a test tube slant medium for Saccharomyces boulardii; mix 1wt% peptone, 1wt% beef extract, and yeast extract 0.5wt%, diammonium hydrogen citrate 0.2wt%, glucose 2wt%, Tween 80 0.1wt%, sodium acetate 0.5wt%, dipotassium hydrogen phosphate 0.2wt%, magnesium sulfate 0.058wt%, manganese sulfate 0.025wt%, Mix 1.8wt% of agar powder and the rest of distilled water in proportion to prepare a 1000ml solution, adjust the pH to 6.2, sterilize at 110°C for 15 minutes, place it on an inclined plane, incubate at 37°C for 24 hours, and conduct a sterility test to obtain Streptococcus ...

Embodiment 2

[0029]Step 1.1: Prepare Saccharomyces boulardii test-tube slant medium and Streptococcus lactis test-tube slant medium respectively: 1wt% of yeast extract, 2wt% of tryptone, 2wt% of glucose, 2wt% of agar powder and the rest of distilled water in proportion Mix and prepare a 1000ml solution, sterilize at 121°C for 15 minutes, place on a slant, incubate at 37°C for 24 hours, and perform a sterility test to obtain a test tube slant medium for Saccharomyces boulardii; mix 1wt% peptone, 1wt% beef extract, and yeast extract 0.5wt%, diammonium hydrogen citrate 0.2wt%, glucose 2wt%, Tween 80 0.1wt%, sodium acetate 0.5wt%, dipotassium hydrogen phosphate 0.2wt%, magnesium sulfate 0.058wt%, manganese sulfate 0.025wt%, Mix 1.8wt% of agar powder and the rest of distilled water in proportion to prepare a 1000ml solution, adjust the pH to 6.6, sterilize at 110°C for 15 minutes, place it on an inclined plane, incubate at 37°C for 24 hours, and conduct a sterility test to obtain Streptococcus l...

Embodiment 3

[0036] Step 1.1: Prepare Saccharomyces boulardii test-tube slant medium and Streptococcus lactis test-tube slant medium respectively: 1wt% of yeast extract, 2wt% of tryptone, 2wt% of glucose, 2wt% of agar powder and the rest of distilled water in proportion Mix and prepare a 1000ml solution, sterilize at 121°C for 15 minutes, place on a slant, incubate at 37°C for 24 hours, and perform a sterility test to obtain a test tube slant medium for Saccharomyces boulardii; mix 1wt% peptone, 1wt% beef extract, and yeast extract 0.5wt%, diammonium hydrogen citrate 0.2wt%, glucose 2wt%, Tween 80 0.1wt%, sodium acetate 0.5wt%, dipotassium hydrogen phosphate 0.2wt%, magnesium sulfate 0.058wt%, manganese sulfate 0.025wt%, Mix 1.8wt% of agar powder and the rest of distilled water in proportion to form a 1000ml solution, adjust the pH to 6.4, sterilize at 110°C for 15 minutes, place it on an inclined plane, incubate at 37°C for 24 hours, and perform a sterility test to obtain Streptococcus lac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com