Etching liquid composition for nickel or nickel/copper alloy

A technology of etching solution and composition, which is applied in the field of microstructure etching, can solve the problems of poor stability of working solution, large copper corrosion, and low nickel etching rate, etc., and achieve the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

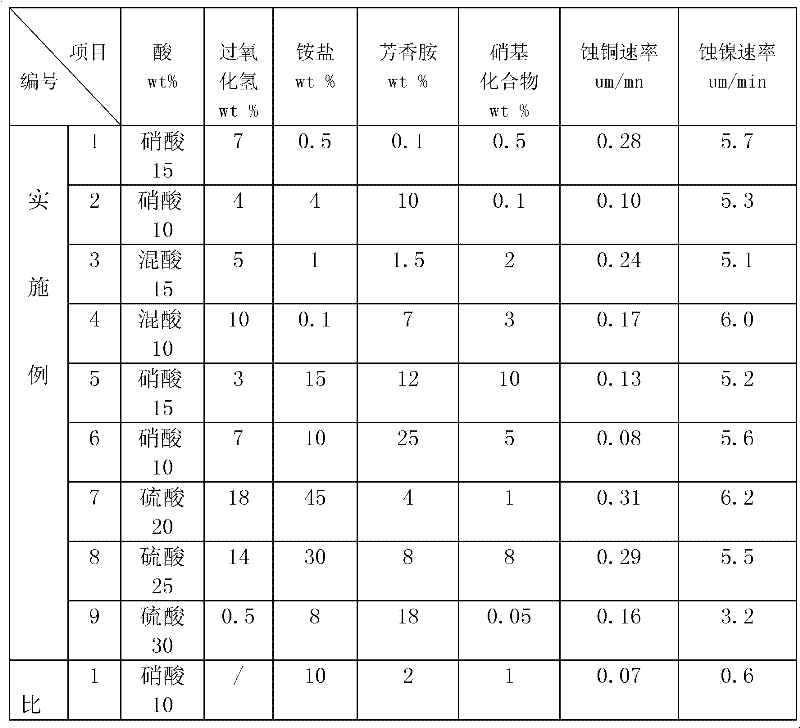

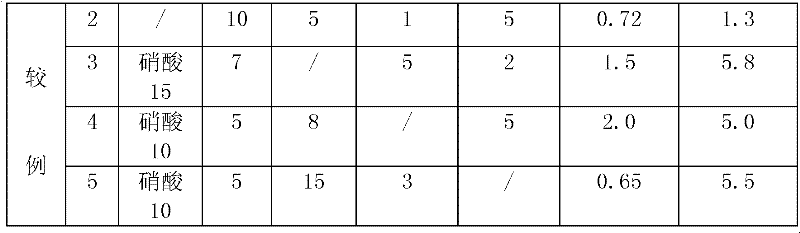

Examples

Embodiment Construction

[0033] The etching solution composition of the present invention is an etching solution containing inorganic acid, hydrogen peroxide and water, wherein the inorganic acid is nitric acid or sulfuric acid or a mixed solution of nitric acid and sulfuric acid; the etching solution composition also contains ammonium salt, aromatic Amines and nitro compounds.

[0034] Ammonium salt has the function of adjusting the concentration of H+. As a specific example of ammonium salt, it can be selected from ammonium sulfate, ammonium bisulfate, ammonium nitrate, ammonium carbonate, ammonium bicarbonate, ammonium formate, ammonium acetate, ammonium benzoate, ammonium chloride, ammonium bromide, ammonium fluoride, ammonia water 1 or 2 of them. The content of the ammonium salt is 0.01-50.0wt%, preferably 0.1-30.0wt%, more preferably 1-15.0wt%. When the concentration is less than 0.01wt%, the regulating effect cannot be achieved; when it is greater than 50.0wt%, no more Good conditioning effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com