Sulfur-carbon composite material for cathode of lithium ion battery, preparation method and lithium ion battery

A sulfur-carbon composite material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low cost, poor cycle stability, and difficulty in mass production of lithium-sulfur batteries. Achieve the effect of excellent electrochemical performance, fine particle size and small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of porous catechol formaldehyde resin

[0032] Add 2.20g of catechol, 2ml of formaldehyde and 5ml of concentrated hydrochloric acid into 10ml of ethanol, stir to dissolve completely, put the above solution into a 50ml autoclave, keep it at 100°C for 5 hours, and synthesize the porous polymer ophthalmic acid. Hydroquinone formaldehyde resin gel; the obtained gel is crushed, dried in vacuum at 80° C. for 12 hours, and the vacuum degree is -0.1 MPa, and the obtained material is ground into powder with a mortar for use.

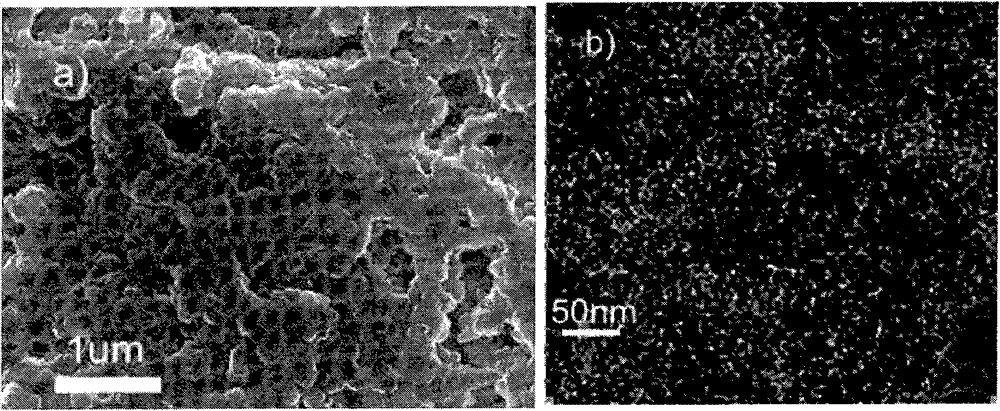

[0033] The obtained phenolic resin scanning electron micrograph is as follows figure 1 As shown in a and b, it can be seen that the sample has a honeycomb structure with small and dense pores. In the low-magnification pictures, it can be seen that there are some independent circular cavities in the sample, and it can be seen that the inner surface is relatively smooth. Synthetic The porous phenolic resin polymer contains micropores of 0.4-...

Embodiment 2

[0038] (1) Preparation of porous hydroquinone formaldehyde resin

[0039] Add 3.30g of hydroquinone, 12ml of formaldehyde and 6ml of concentrated hydrochloric acid into 20ml of ethanol, stir to dissolve it completely, put the above solution into a 50ml autoclave, keep it warm at 120°C for 10 hours, mash the resulting gel, Vacuum drying at 100°C for 12 hours, vacuum degree -0.1MPa, porous hydroquinone formaldehyde resin, and grinding the obtained material into powder with a mortar for use.

[0040] (2) Preparation of sulfur-carbon composite materials

[0041] Mix the polymer phenolic resin and sulfur powder obtained in step (1) uniformly in a mass ratio of 1:2, heat at a heating rate of 5°C / min under the protection of argon, and roast at a constant temperature of 300°C for 2 hours to obtain elemental sulfur / Sulphur-containing polymer composite material, the sulfur content of which is 47.08wt%.

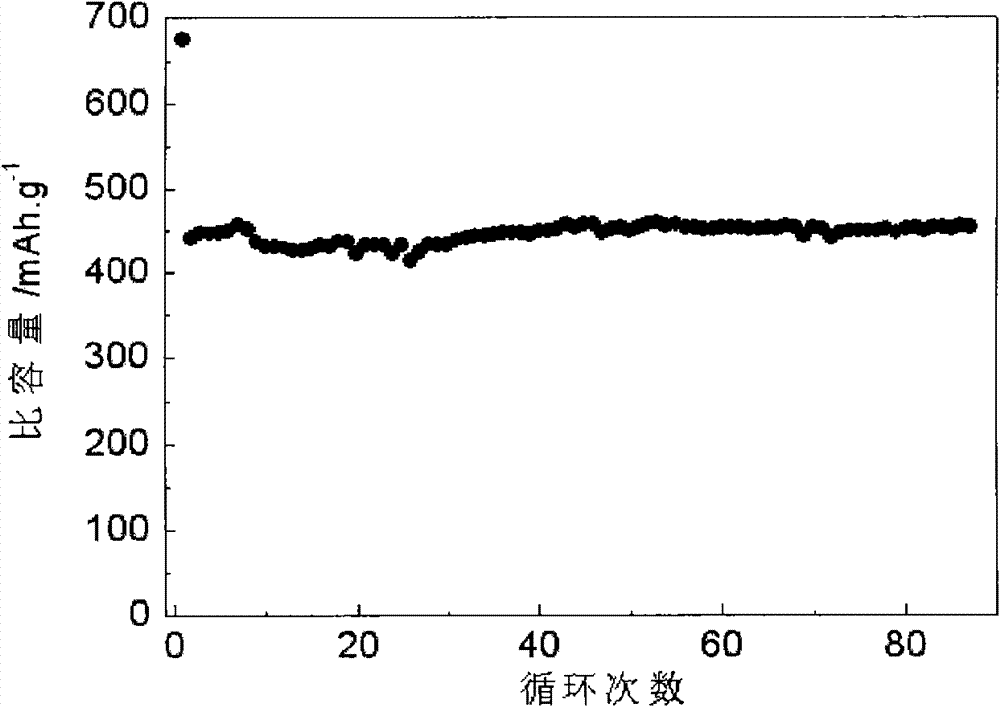

[0042] The obtained positive electrode material is mixed with conductive agent a...

Embodiment 3

[0044] (1) Preparation of porous phenol-formaldehyde resin

[0045] Add 2.82g of phenol, 6ml of formaldehyde and 0.5g of sodium hydroxide into 20ml of deionized water, stir to dissolve it completely, put the above solution into a 50ml autoclave, keep it warm at 150°C for 5 hours, mash the resulting gel, 120 ℃ temperature vacuum drying for 6 hours, vacuum degree -0.1MPa, porous phenol-formaldehyde resin, the obtained material is ground into powder with a mortar for use.

[0046] (2) Preparation of sulfur-carbon composite materials

[0047] The polymer phenolic resin and sulfur powder obtained in step (1) are uniformly mixed in a mass ratio of 1:3, under the protection of a mixed gas of 95% argon and 5% hydrogen, heated at a heating rate of 5°C / min, at 400°C Calcined at constant temperature for 1 hour to obtain elemental sulfur / sulfur-containing polymer composite material with a sulfur content of 41 wt%.

[0048] The obtained positive electrode material is mixed with conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com