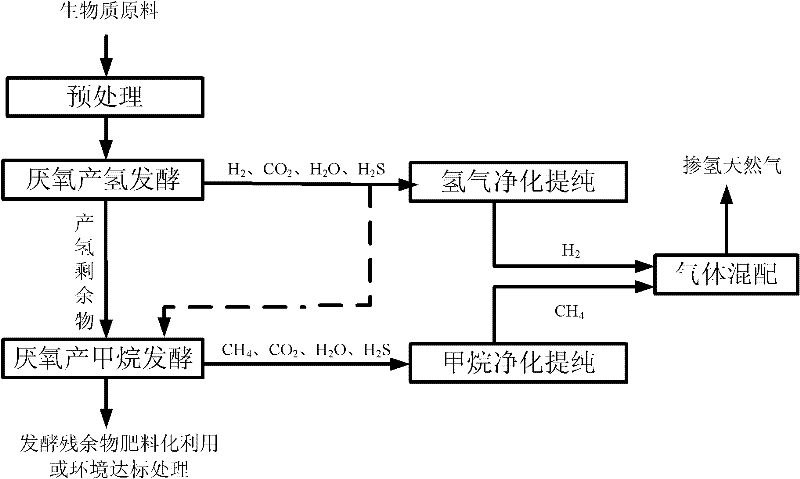

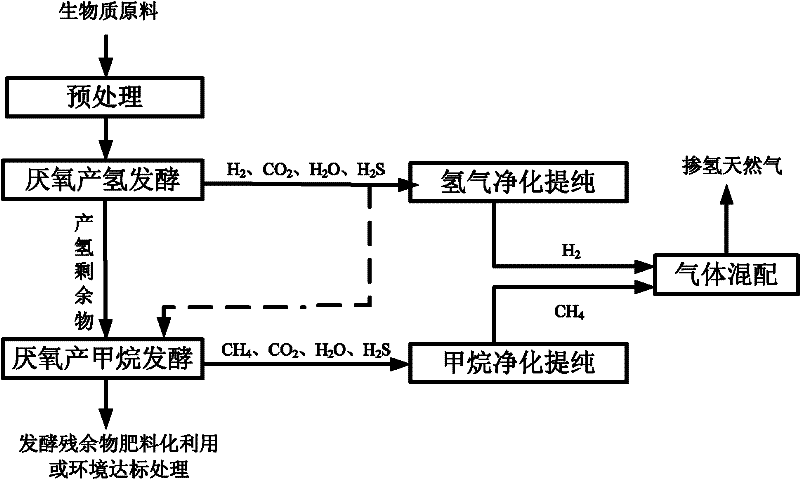

Method for preparing hydrogen-blended natural gas by using biomass raw materials

A biomass raw material and natural gas technology, applied in the direction of waste fuel, fermentation, etc., can solve the problems of low and limited energy recovery efficiency, achieve the effects of easy control of hydrogen doping ratio, simple production process, and promotion of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Using slaughterhouse waste as biomass raw material, the anaerobic activated sludge from the biogas tank was treated at 80°C for 60 minutes to obtain the hydrogen-producing inoculum. After the slaughterhouse waste was crushed, it entered the anaerobic hydrogen-producing reaction together with the hydrogen-producing inoculum. control the pH in the anaerobic hydrogen production reactor to be 4.5-6.5 for anaerobic hydrogen production fermentation; the hydrogen production residue discharged from the anaerobic hydrogen production reactor is mixed with anaerobic activated sludge Methane reactor, control the pH in the anaerobic methanogenesis reactor to 6.5-7.8 for anaerobic methanogenesis fermentation; complete the residue of methanogenesis fermentation for environmental standard treatment; H from the anaerobic hydrogen production fermentation reactor 2 , CO 2 、H 2 S, H 2 O(g) mixed gas, remove H through the desulfurization and decarburization process of alcohol amine chemic...

Embodiment 2

[0031] Using food waste as biomass raw material, take the anaerobic activated sludge from the sewage treatment plant and treat it at 100°C for 30 minutes to obtain the hydrogen-producing inoculum. Hydrogen production reactor, control the pH in the anaerobic hydrogen production reactor to 4.5-6.5 for anaerobic hydrogen production fermentation; the hydrogen production residue discharged from the anaerobic hydrogen production reactor is mixed with the anaerobic activated sludge of the sewage treatment plant Enter the anaerobic methanogenesis reactor, control the pH in the anaerobic methanogenesis reactor to 6.5-7.8 to carry out anaerobic methanogenesis fermentation; complete the residue of methanogenesis fermentation and apply it to the farmland after simple processing; from the anaerobic hydrogen production fermentation reaction H 2 , CO 2 、H 2 S, H 2 O(g) mixed gas, through the desulfurization and decarburization process of polyethylene glycol dimethyl ether physical absorpt...

Embodiment 3

[0034] Using sugar wastewater as biomass raw material, the anaerobic activated sludge from the biogas tank was treated at 115°C for 15 minutes to obtain hydrogen-producing inoculum. Sugar wastewater and hydrogen-producing inoculum entered the anaerobic hydrogen-producing reactor to control the The pH in the hydrogen production reactor is 4.5 to 6.5 for anaerobic hydrogen production fermentation; the hydrogen production residue discharged from the anaerobic hydrogen production reactor is mixed with the anaerobic activated sludge of the biogas tank and then enters the anaerobic methane production reactor. The pH in the anaerobic methanogenic reactor is 6.5-7.8 for anaerobic methanogenic fermentation; 2 , CO 2 、H 2 S, H 2 O(g) mixed gas, through molecular sieve pressure swing adsorption desulfurization and decarburization process to remove H 2 S and CO 2 , and then get pure hydrogen through molecular sieve adsorption and deep dehydration; CH from the anaerobic methanogenic fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com