Dust prevention and sand fixation method

A sand-fixing method and a sand-fixing agent technology are applied in the fields of botanical equipment and methods, horticulture, soil protection, etc., and can solve the problems of consolidation strength, environmental stability, moisture absorption and water retention, wind erosion resistance, low cost, and ecological environmental protection. Achieve good economic performance, strong practicability, and the effect of being conducive to vegetation growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 30g number-average molecular weight in reaction vessel and be the polyoxypropylene diol of 2000, 60g number-average molecular weight be the polyoxyethylene diol of 1000 and 27g number-average molecular weight be the polyε-caprolactone diol of 2000, remove water Treatment: under the condition of nitrogen protection, add 23.4 g of toluene diisocyanate into the reaction vessel, control the temperature at 85° C., and react for 2 hours.

[0020] After cooling, add 200ml of ethyl acetate to the reaction system, and stir at room temperature for 1.5h. After discharging, add sodium dodecylbenzene sulfonate accounting for 5% of the mass of the polyurethane prepolymer, and stir thoroughly to prepare a polyurethane type ecological sand-fixing agent, which is sealed and stored.

[0021] Unconfined compressive strength and shear tests were carried out on the sand-fixing agent prepared in this example.

[0022] (1) Unconfined compressive strength test

[0023] The unconfined com...

Embodiment 2

[0035] Put 340g (recorded as m0) of sand taken from the site into a tray with a size of 16cm×16cm×3cm, and compact it for sample preparation. Prepare sand-fixing agent dilutions with different concentrations and proportions according to Table 3, and spray evenly on the surface of sandy soil sample 1, and the spraying amount is 3L / m 2 , placed at room temperature for 24h.

[0036] Table 3 Proportion of dilution solution of polyurethane type ecological sand-fixing agent

[0037] Concentration (weight)%

0

0.5

1

1.5

2

3

5

Polyurethane prepolymer (g)

0

5

10

15

20

30

50

Solvent (g)

0

6.19

12.38

18.57

24.76

30.95

37.14

water (g)

1000

988.81

977.62

966.43

955.24

939.05

912.86

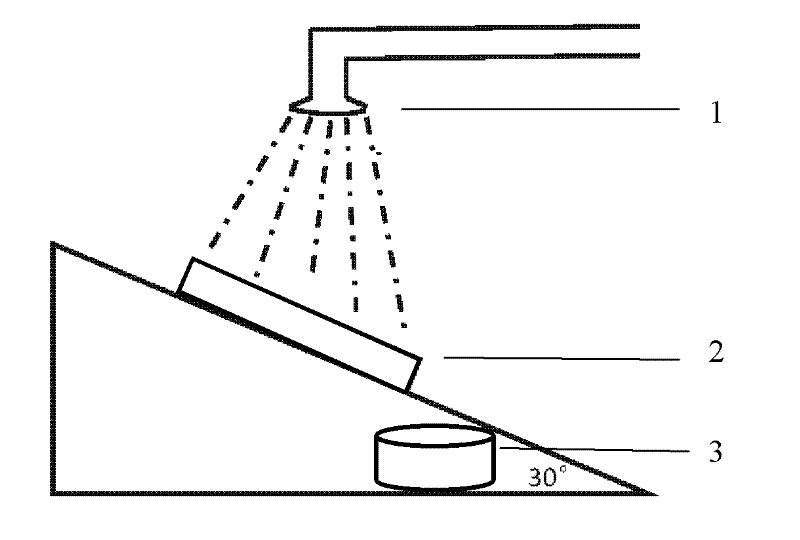

[0038] Such as figure 1 As shown, the sand sample 1 was placed on a slope frame with a slope of 30° to ca...

Embodiment 3

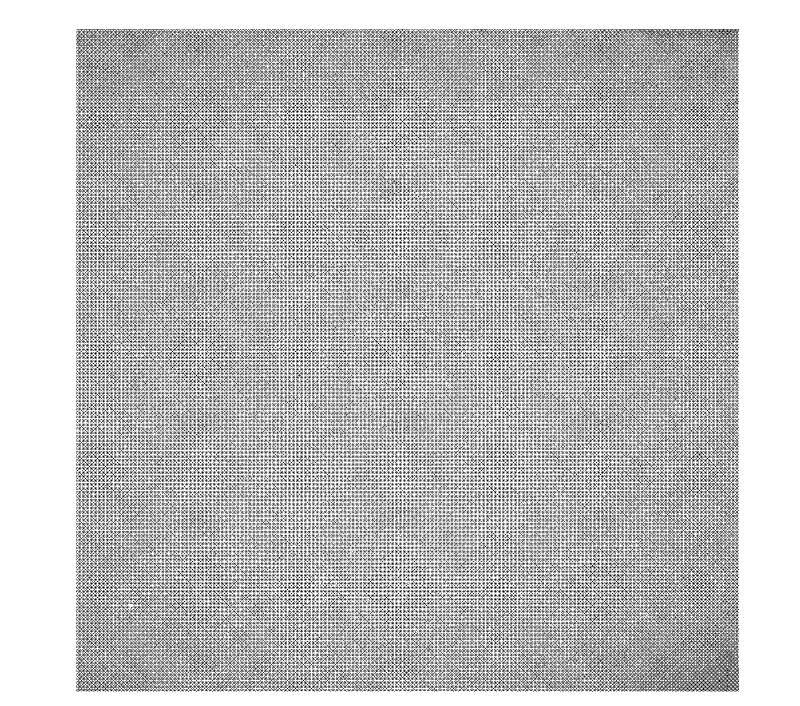

[0043] Spread fine sand evenly in a tray of 30cm×30cm×2cm, prepare sand-fixing agent dilutions with different concentrations and ratios according to Table 5, and spray evenly on the surface of the sand sample, and the spraying amount is 3L / m 2 , placed at room temperature for 24h.

[0044] Table 5 Proportion of dilution solution of polyurethane type ecological sand-fixing agent

[0045] Concentration (weight)%

0

0.5

1

1.5

2

3

Polyurethane prepolymer (g)

0

15

30

45

60

90

Solvent (g)

0

18.57

37.14

55.71

74.28

111.42

water (g)

3000

2966.43

2932.86

2899.29

2865.72

2798.58

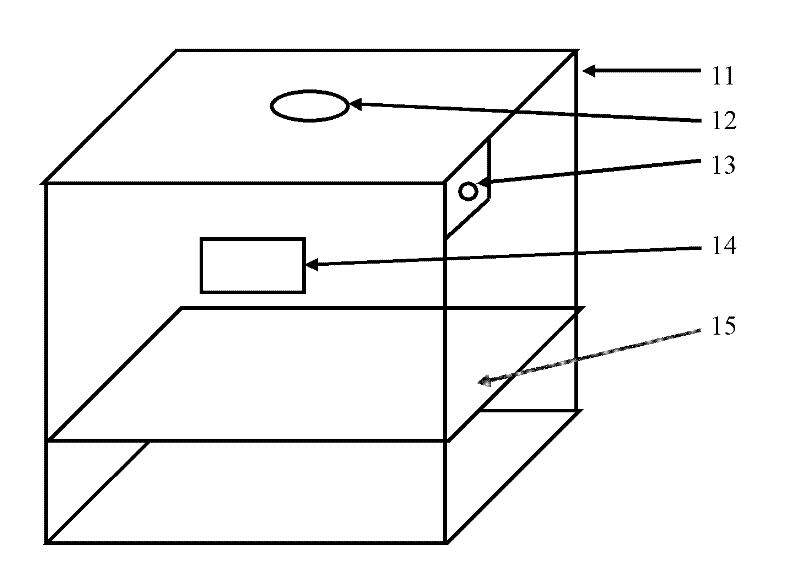

[0046] Such as figure 2 As shown, the simulation box 11 is used to carry out the simulation test of wind erosion resistance. The tray 15 is put into the simulation box 11, the switch 13 is turned on, and the blower 12 with adjustab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com