An electrochemical method for the controllable preparation of silicon nanostructure materials

A structural material, silicon nanotechnology, applied in the direction of anodic oxidation, etc., to achieve the effect of easy separation or transfer, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

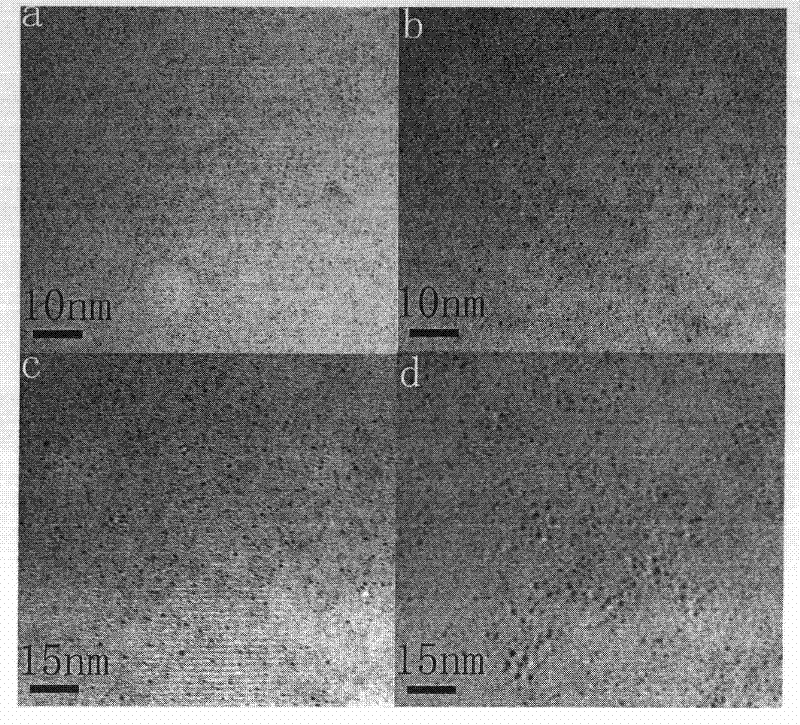

[0028] Embodiment 1, preparation particle diameter is the silicon quantum dot of 1-4nm

[0029] Mix ethanol solution with a mass concentration of 95%, hydrofluoric acid solution with a mass concentration of 20%, and hydrogen peroxide with a mass concentration of 30% in a volume ratio of 2:1:0.1, add phosphotungstic acid, and make the electrolyte The concentration of phosphotungstic acid in the mixture is 0.02 mg / mL, and after stirring evenly, an electrolyte solution for preparing silicon quantum dots is obtained.

[0030] P-type silicon wafer (conductivity 0.005-30Ω, reaction area 0.5-1cm 2) soaked in hydrofluoric acid with a mass concentration of 5% for 2-5 minutes, then rinsed with ethanol and distilled water in sequence, and then used as an anode, and a graphite rod as a cathode. Take 100ml of electrolytic solution and place it in a plastic electrolytic cell, and add 30 milliliters of cyclohexane into the electrolytic solution (reaction system) to form an organic solvent l...

Embodiment 2

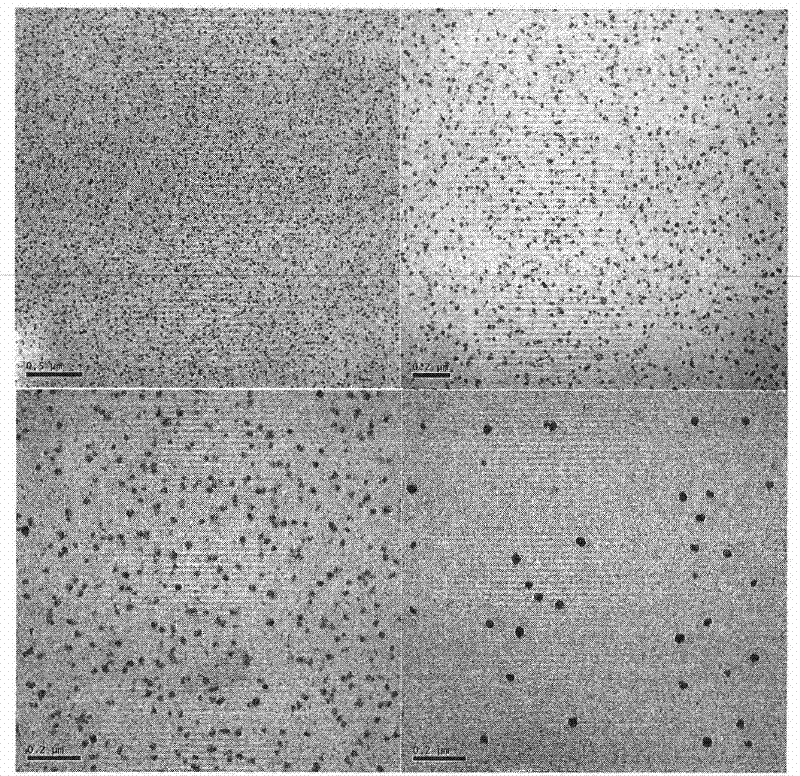

[0031] Embodiment 2, preparation silicon nanoparticle

[0032] Mix 95% ethanol solution and 20% hydrofluoric acid solution according to the volume ratio of 1.5:1, add phosphomolybdic acid, so that the concentration of phosphomolybdic acid in the electrolyte is 0.03 mg / mL, and stir evenly to obtain Electrolyte for silicon quantum dots. Silicon wafer (conductivity 0.005-30Ω, reaction area 0.5-1cm 2 ) soaked in 5% hydrofluoric acid for 2-5 minutes, then rinsed with ethanol and distilled water successively, and then used as an anode, and a graphite rod as a cathode. Take 100ml of electrolytic solution and place it in a plastic electrolytic cell, and add 30ml of cyclohexane into the electrolytic solution to form an organic solvent liquid film above the electrolytic solution. at 15-20mA / cm 2 Under the current density of , the electrochemical oxidation reaction was carried out for 30 minutes, and silicon nanoparticles with a diameter of about 30 nanometers were obtained on the ano...

Embodiment 3

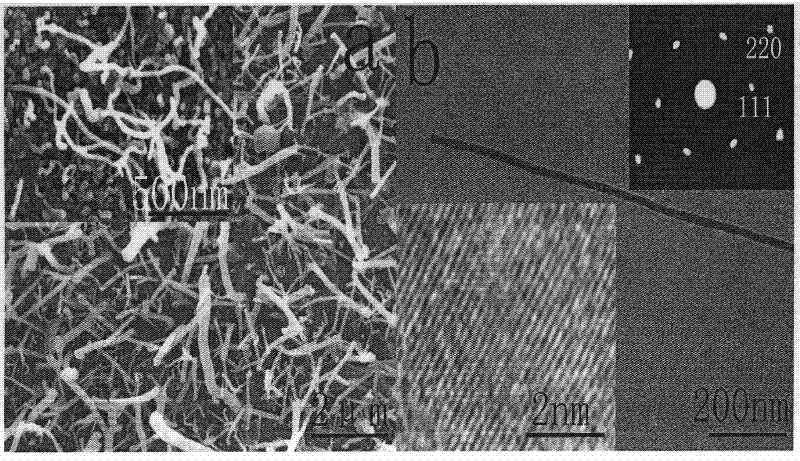

[0033] Embodiment 3, preparation silicon nanowire

[0034] Prepare according to the method of Example 2, but change the current density of the reaction to 20-50mA / cm 2 , carry out the electrochemical redox reaction for 30-60 minutes, and obtain silicon nanowires with a diameter of about 30-80 nanometers on the anode silicon wafer. After the reaction, monodisperse silicon nanowires can be obtained by ultrasonically treating the anode silicon wafer in methanol or ethanol. image 3 . image 3 The inset in a is a partial enlargement, image 3 The upper inset in b is an electron diffraction pattern, and the lower inset is a high-resolution electron micrograph.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com