Metal-powder type stainless steel flux-cored wire

A technology for flux-cored welding wire and stainless steel, which is applied in the field of flux-cored welding wire and metal powder type stainless steel flux-cored welding wire, can solve the problems of unreasonable flux-cored powder compatibility, brittle change of weld metal, poor weld toughness, etc., so as to improve the smoke and dust. The effect of large, stable arc combustion and fast deposition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

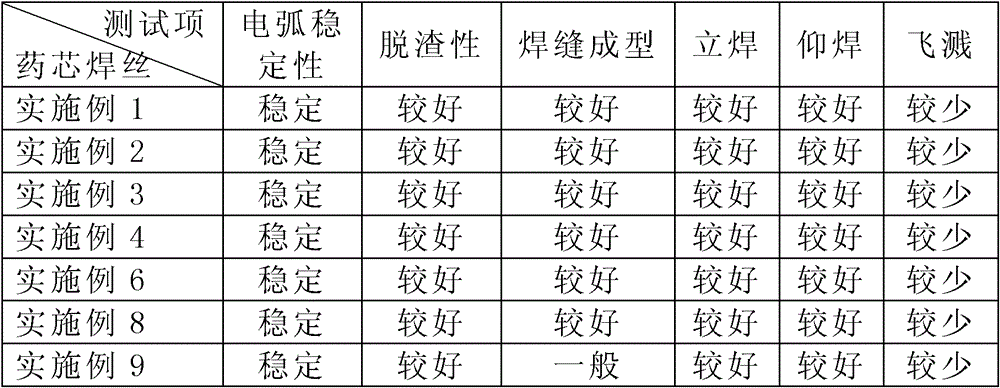

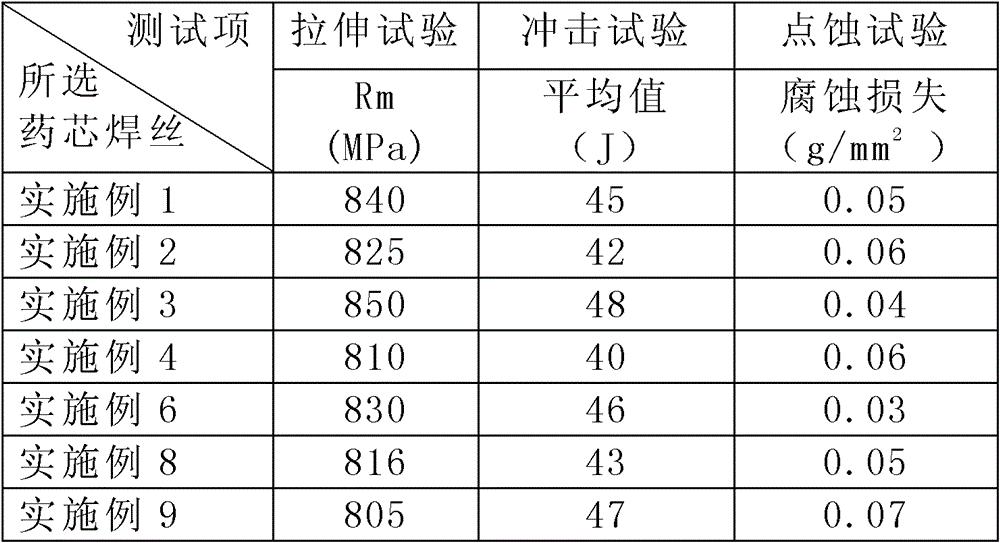

Examples

Embodiment 1

[0031] The selected drug core is composed of the following components by weight:

[0032] Chromium powder: 15%; nickel powder: 10%; molybdenum powder: 0.5%; manganese powder: 0.2%; arc stabilizer: 1.0%; the balance is iron powder; the arc stabilizer is potassium fluoride. The selected powders and materials are put into the mixer and mixed evenly for later use;

[0033] A 308L stainless steel strip with a width of 12mm and a thickness of 0.4mm is selected as the sheath of the flux-cored welding wire of the present invention. After the selected stainless steel strip is derusted and degreasing, it is pressed into a U-shape by a forming machine; The drug core is filled into the U-shaped groove to make the filling rate 32.5%, and then the opening of the U-shaped groove is closed to form an O shape, so that the drug core is wrapped in it, and then it is drawn and reduced step by step through a wire drawing machine. Finally, the diameter is 1.0 mm to obtain the metal powder type stainles...

Embodiment 2

[0035] The selected drug core is composed of the following components by weight:

[0036] Chromium powder: 25%; nickel powder: 10%; molybdenum powder: 0.2%; manganese powder: 0.6%; arc stabilizer: 3.0%; slag remover: rare earth element (RE); the balance is iron powder; also includes 0.2 % Chromium nitride powder, the arc stabilizing agent is aluminum powder, the slag remover is rare earth element (RE), and the rare earth element (RE) is cerium, lanthanum, praseodymium, neodymium, scandium One; the addition of chromium nitride is beneficial to synergize with aluminum powder as a slag remover, so as to form a stable slag remover, and is also beneficial to improve the strength and toughness of the weld; the selected above The powder and materials are put into the mixer and mixed uniformly to obtain the drug core of the present invention, which is ready for use;

[0037] A 308L stainless steel strip with a width of 8mm and a thickness of 0.7mm is selected as the outer sheath of the fl...

Embodiment 3

[0039] The selected drug core is composed of the following components by weight:

[0040] Chromium powder: 22%; Nickel powder: 15%; Molybdenum powder: 0.1%; Manganese powder: 0.4%; Arc stabilizer: 2.0%; Deslagging agent: 0.5%; the balance is iron powder; the arc stabilizer It is a manganese-silicon alloy, the slag remover is rare earth element (RE), and the rare earth element (RE) is one of cerium, lanthanum, praseodymium, neodymium, and scandium; the selected powder materials Put them into the mixer and mix uniformly to obtain the drug core of the present invention, which is ready for use;

[0041] A 308L stainless steel strip with a width of 8mm and a thickness of 0.7mm is selected as the outer sheath of the flux-cored welding wire of the present invention. After the selected stainless steel strip is derusted and degreasing, it is pressed into a U-shape by a forming machine; The uniformly mixed drug core is filled into the U-shaped groove to make the filling rate 40%, and the op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com