A kind of camphor leaf volatile oil clathrate and preparation method thereof

A technology of clathrate of volatile oil and camphor leaves, applied in the biological field of Microsporum ointment), insecticidal, analgesic and anti-inflammatory effects, which can solve the problems of unfavorable feed storage, reduced bioavailability, easy mildew, etc. To achieve the effect of improving bioavailability, improving stability and protecting drug efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

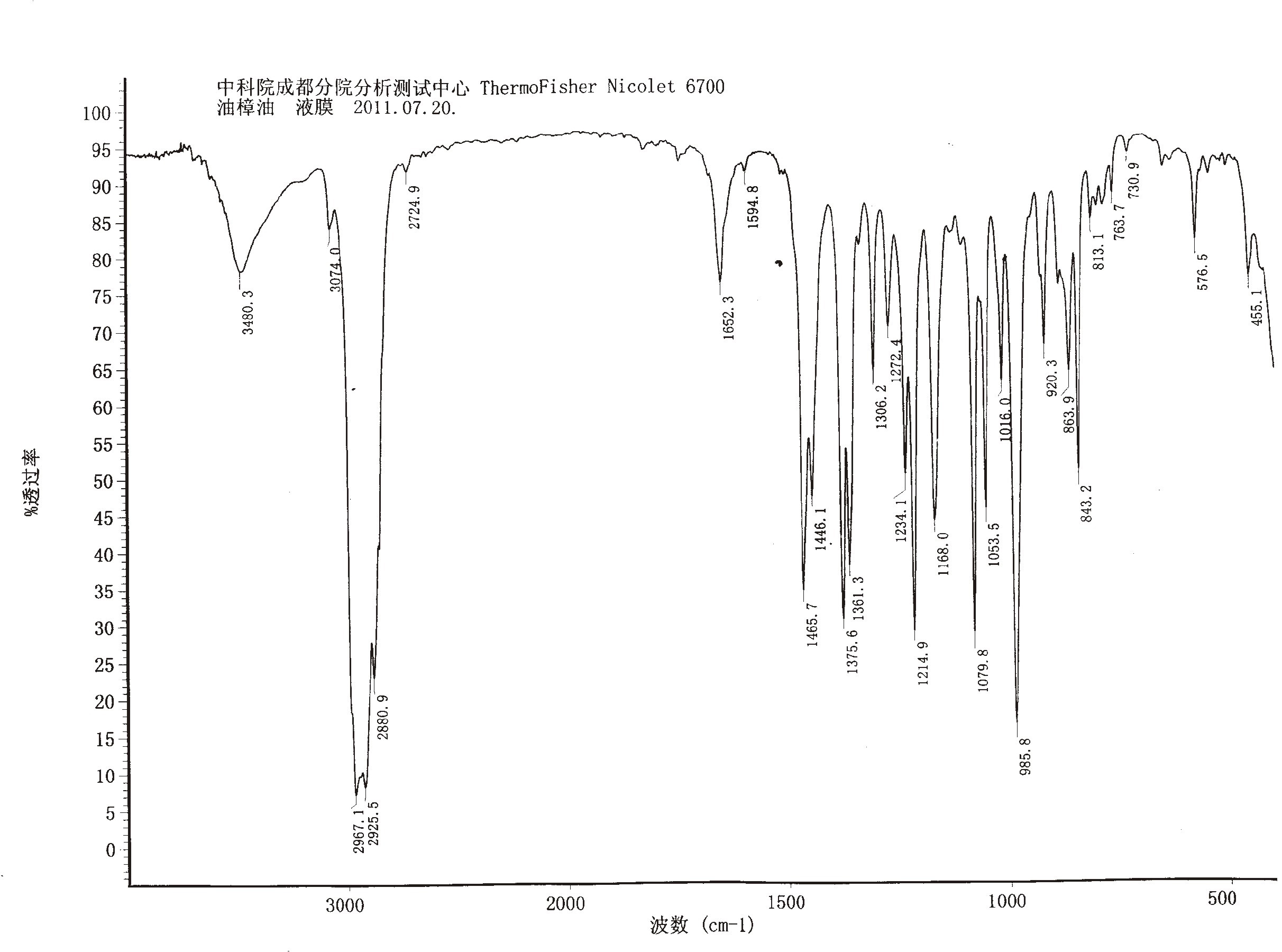

[0035] Preparation of volatile oil from camphor leaves: wash fresh camphor leaves, cut them into pieces, put them in a flask, and extract them with steam distillation in a volatile oil extraction device. Sodium sulfate drying, to obtain camphor leaf volatile oil.

[0036] Accurately weigh 4g of β-cyclodextrin, prepare a solution according to the ratio of β-cyclodextrin:water 1:20, and heat it in a water bath at 60°C until dissolved. Take another 1ml of camphor volatile oil and dissolve it with 1ml of polyethylene glycol 400, slowly drop the polyethylene glycol solution of camphor volatile oil into the aqueous solution of β-cyclodextrin at constant temperature (60°C) under stirring, and wait until all the drops are finished , and continue to stir for 3h under the condition of heat preservation. Refrigerate the formed clathrate suspension (0°C) for 24 hours, filter with suction, discard the filtrate, wash the clathrate with distilled water, drain it and dry it at low temperatur...

Embodiment 2

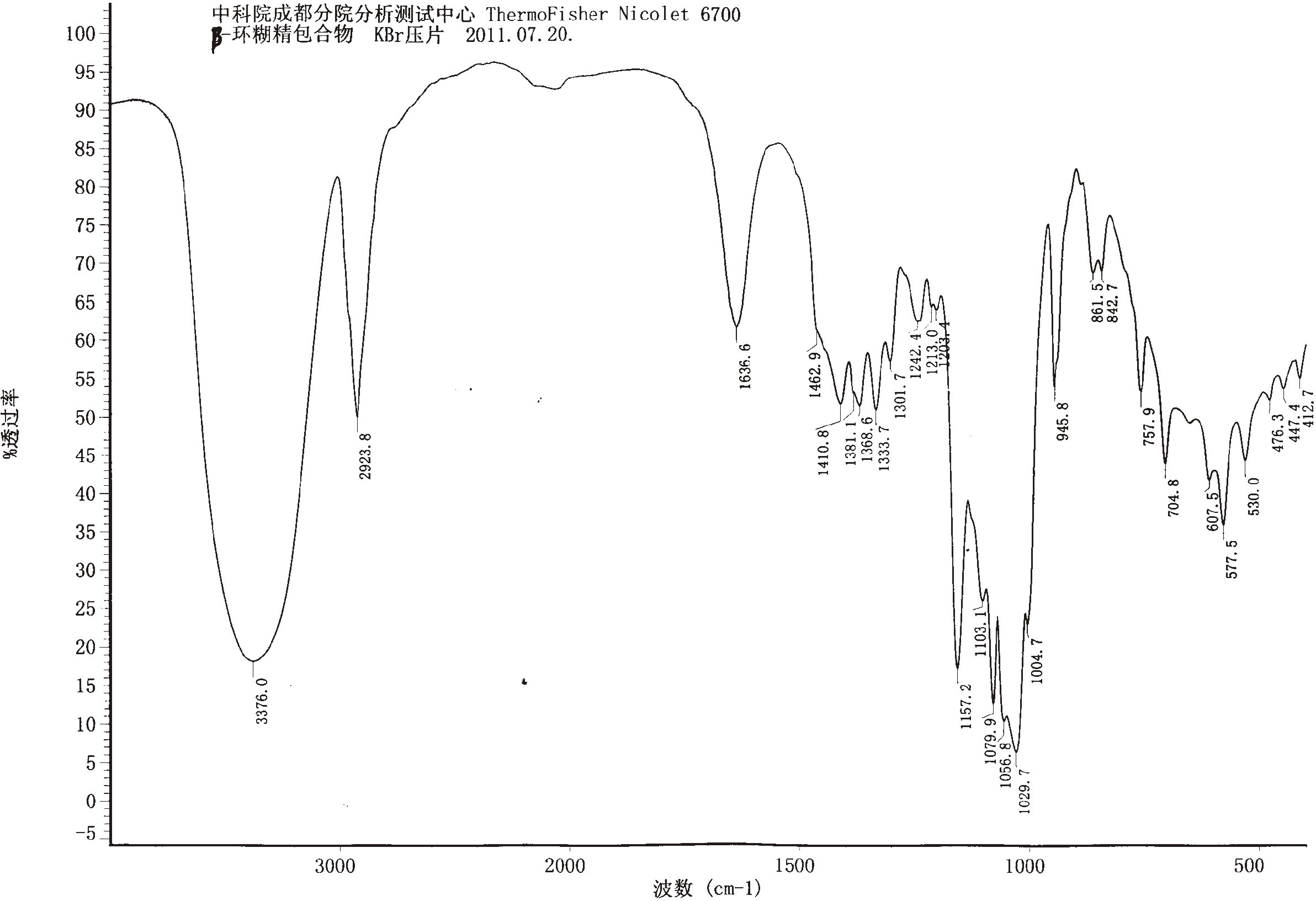

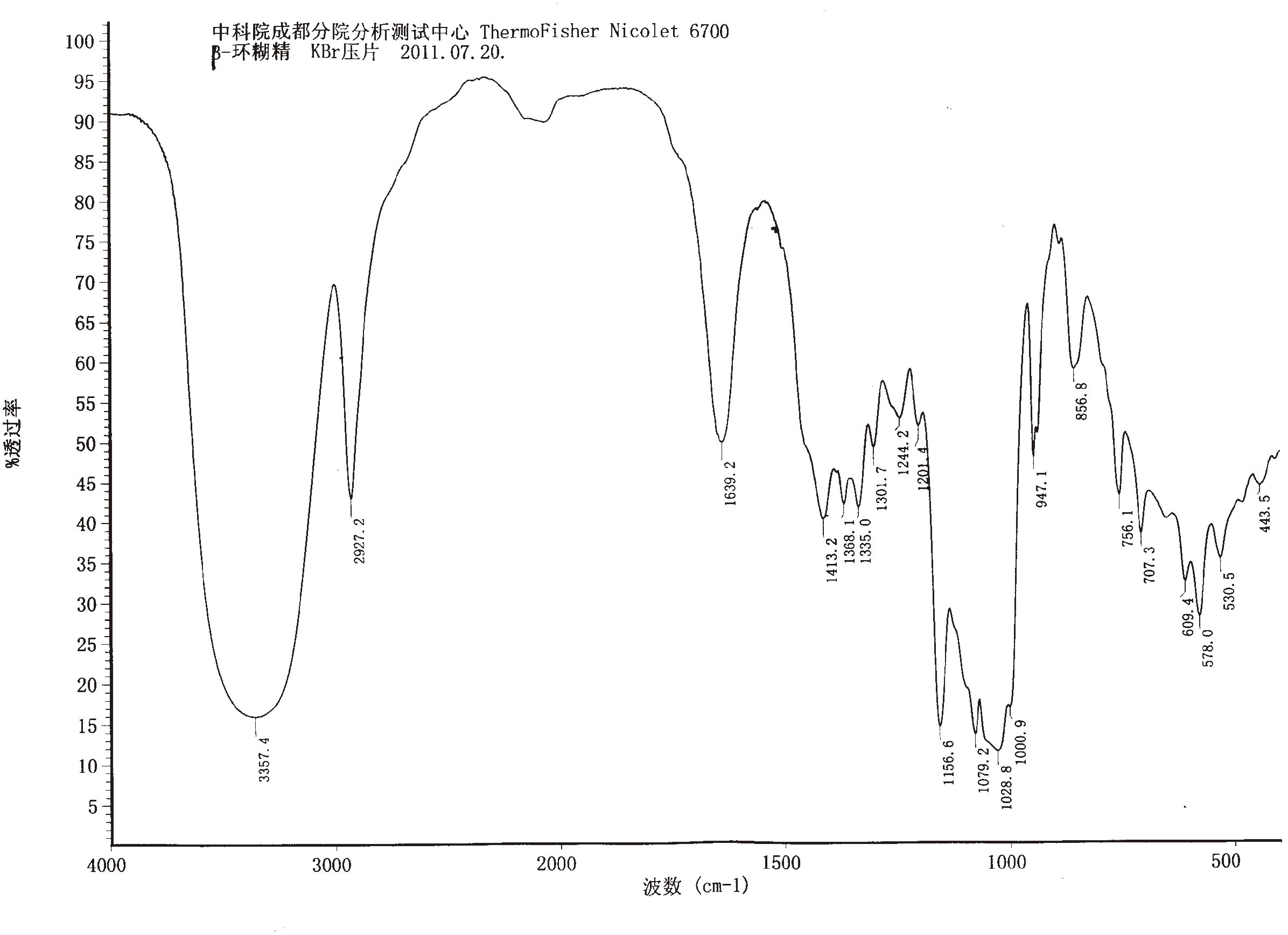

[0038] Accurately weigh 6g of β-cyclodextrin, prepare a solution according to the ratio of β-cyclodextrin:water 1:10, and heat it in a water bath at 50°C until dissolved. Take another 1ml of camphor volatile oil and dissolve it with 1ml of polyethylene glycol 400, and slowly drop the polyethylene glycol solution of camphor volatile oil into the β-cyclodextrin solution at a constant temperature (50°C) under stirring. After all the drops are finished, Continue to stir at constant temperature for 3h. Refrigerate the formed clathrate suspension (0°C) for 24 hours, filter with suction, discard the filtrate, wash the clathrate with distilled water, drain it and dry it at low temperature to finally obtain the clathrate. The yield of inclusion compound prepared under this condition was 90.82%, and the inclusion rate was 72.22%. Fourier transform infrared spectroscopy (FI-IR) confirmed the formation of clathrates.

Embodiment 3

[0040] Accurately weigh 8g of β-cyclodextrin, prepare a solution according to the ratio of β-cyclodextrin:water 1:15, and heat in a water bath at 40°C until dissolved. Take another 1ml of camphor volatile oil and dissolve it with 1ml of polyethylene glycol 400, and slowly drop the polyethylene glycol solution of camphor volatile oil into the β-cyclodextrin solution at constant temperature (40°C) under stirring. After all the drops are finished, Continue to stir for 3h under the condition of heat preservation. Refrigerate the formed clathrate suspension (0°C) for 24 hours, filter with suction, discard the filtrate, wash the clathrate with distilled water, drain it and dry it at low temperature to finally obtain the clathrate. The yield of clathrate prepared under this condition was 78.59%, and the inclusion rate was 80.00%. Fourier transform infrared spectroscopy (FI-IR) confirmed the formation of clathrates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com