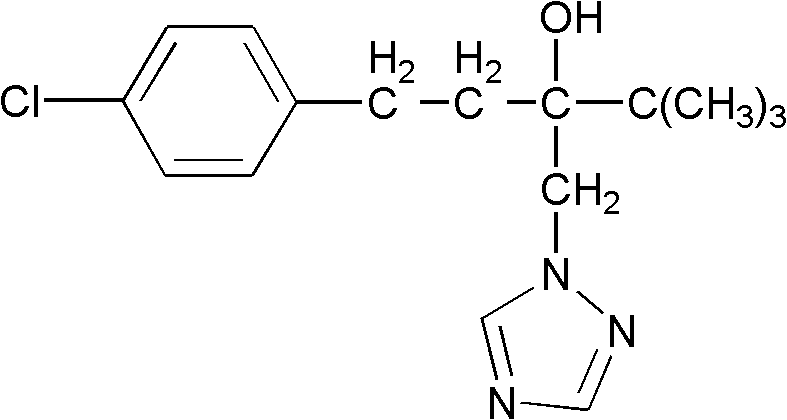

Tebuconazole-algae slow-release microcapsule fungicide and preparation method thereof

A tebuconazole, sustained-release technology, applied in the field of tebuconazole-algae sustained-release microcapsule fungicide and its preparation, can solve the adverse effects of the surrounding environment, the difficulty of exerting super-efficient effects, and the increase in dosage and frequency and other problems, to achieve the effect of reducing the dosage, low cost and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] a. Take the pretreated Microcystis powder and dry it at 50°C for 7 hours;

[0038] b. Dissolve 1 part of tebuconazole, 0.25 part of naphthalene acetic acid and 0.75 part of indolebutyric acid in a reactor filled with 6.25 parts of ethanol, and add 5 parts of dried algal powder, and place in a constant temperature air bath shaker for 25 Shaking and soaking at ℃ for 24 hours;

[0039] c, adding 0.5 part of carboxymethyl cellulose to the material obtained in step b;

[0040] d, 0.75 parts of sodium lignosulfonate and 1 part of sodium dodecyl sulfonate are dissolved in 25 parts of twice distilled water;

[0041] e. After mixing the substance of step c with the substance of step d, first use a high-shear emulsifier to stir at a speed of 12000rpm for 15 minutes, evaporate ethanol at 40°C, solidify into capsules, filter to remove water, and mix with 1 part of zinc sulfate Mix evenly to obtain the tebuconazole-algae sustained-release microcapsule fungicide.

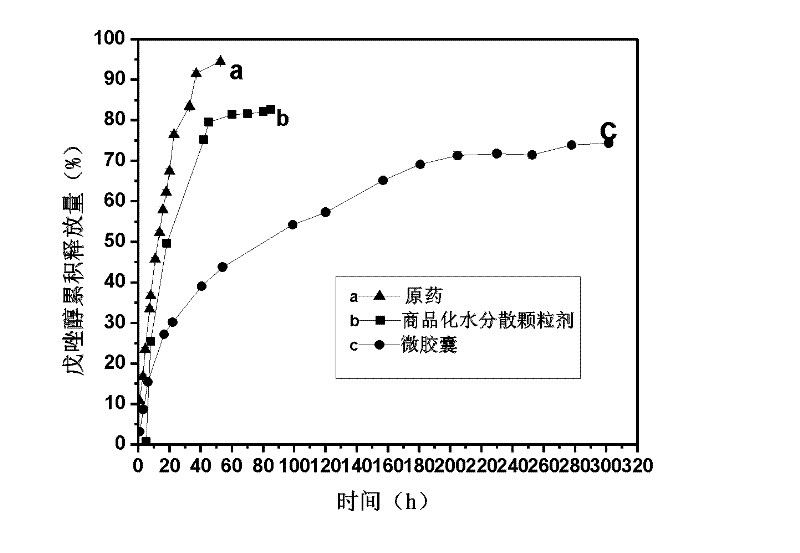

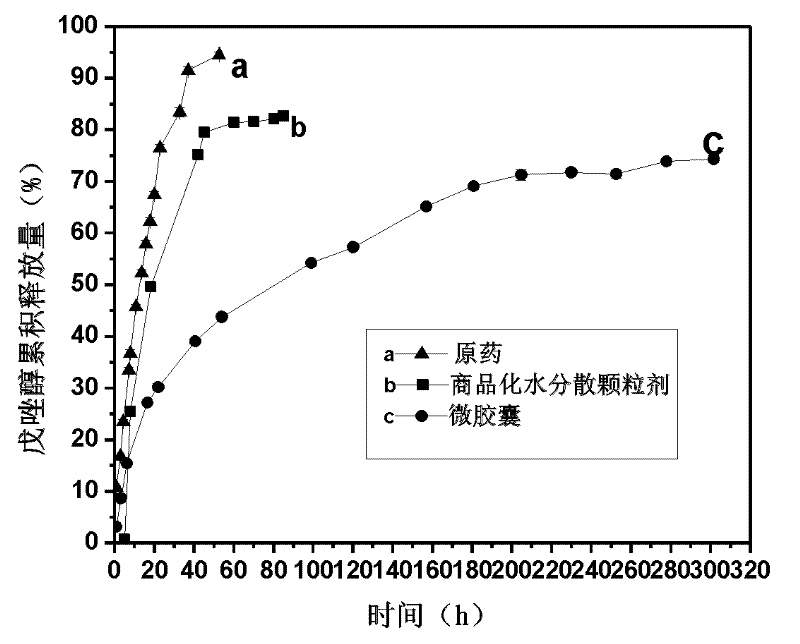

[0042] The prep...

Embodiment 2

[0044] a. Take the pretreated Microcystis powder and dry it at 70°C for 4 hours;

[0045] b. Dissolve 1 part of tebuconazole, 0.4 part of naphthalene acetic acid and 0.1 part of indolebutyric acid in a reactor containing 6 parts of methanol, and add 5 parts of dried algae powder, and place in a constant temperature air bath shaker Shaking and soaking at 25°C for 24 hours;

[0046] c, adding 0.6 part of hydroxyethyl cellulose to the material obtained in step b;

[0047] d, 0.6 parts of polyvinyl alcohol and 1 part of sorbitan monolaurate are dissolved in 30 parts of twice distilled water;

[0048] e. After mixing the substance of step c with the substance of step d, first stir it with a high-shear emulsifier at a speed of 10000rpm for 15 minutes, steam methanol at 50°C, solidify into a capsule, filter to remove water, and mix with 1.4 parts of rare earth nitrate Mix evenly to obtain the tebuconazole-algae sustained-release microcapsule fungicide.

Embodiment 3

[0050] a. Take the pretreated Microcystis powder and dry it at 50°C for 6 hours;

[0051] b. Dissolve 1 part of tebuconazole, 0.6 part of naphthalene acetic acid, and 0.16 part of indole butyric acid in a reactor containing 14 parts of propanol, and add 6 parts of dried algae powder, and place in a constant temperature air bath shaker for 25 Shaking and soaking at ℃ for 24 hours;

[0052] c, 0.6 part of polyvinyl alcohol is added in the material gained in step b;

[0053] d, 0.8 parts of hydroxymethylcellulose and 1.6 parts of polypropylene glycol ethylene oxide ether are dissolved in 40 parts of double distilled water;

[0054] e. After mixing the substance of step c with the substance of step d, first stir it with a high-shear emulsifier at a speed of 10000rpm for 15 minutes, evaporate the propanol at 55°C, solidify into a capsule, filter to remove water, and mix with 1.2 parts of sulfuric acid Mix the ferrous iron evenly to obtain the tebuconazole-algae sustained-release ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com