Method for producing acetone and butanol by co-fermenting cellobiose, pentaglucose and hexose

A technology of cellobiose and acetone butanol, which is applied in the field of co-fermentation of cellobiose, pentose and hexose to produce acetone butanol, to achieve the effect of reducing costs, promoting the diversification of energy structure, and ensuring the safety of liquid fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

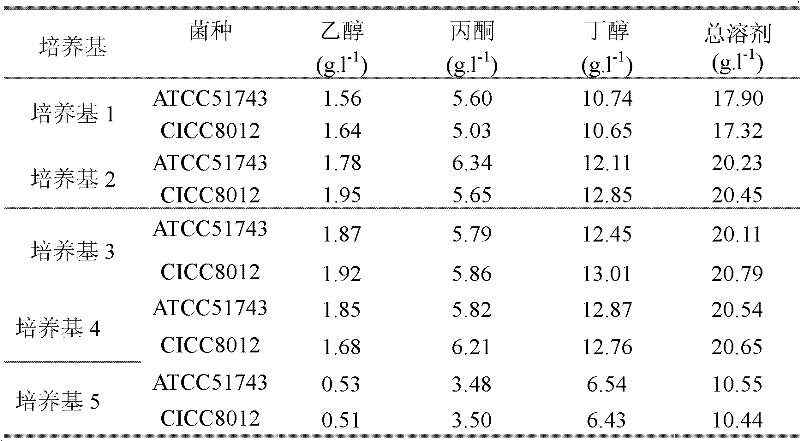

[0026] Example 1: Co-fermentation of cellobiose, xylose and glucose mixed sugar adding organic and inorganic nitrogen and phosphorus substances

[0027] The sugar content after hydrolysis of corn stalks is: xylose 10g / L, glucose 25g / L, cellobiose 16g / L, other sugar 5g / L, total sugar 56g / L.

[0028] Medium 1: Add calcium superphosphate at 1.5% of the total sugar content, add ammonium sulfate at 1.5% of the total sugar content, add 10M / L Ca(OH) 2 Emulsion, adjusted to pH 6.0, divided into 250ml Erlenmeyer flasks, 150ml each, and sterilized in a sterilizer at 121°C for 120 minutes;

[0029] Medium 2: add calcium superphosphate according to 5% of the total sugar content, add ammonium sulfate according to 5% of the total sugar content, add 1M / L acetic acid aqueous solution, adjust the pH to 4.5, divide into 250ml Erlenmeyer flasks, each Erlenmeyer flask 150ml, sterilized in a sterilizing pot at 121°C for 120 minutes;

[0030] Medium 3: Add yeast powder according to 10% of the tot...

Embodiment 2

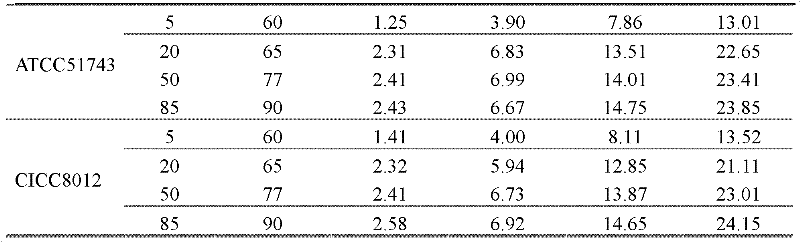

[0038] Embodiment 2: add corn meal fermentation in the corncob hydrolyzate

[0039] The sugar content was measured after the corncob was hydrolyzed, xylose 12g / L, glucose 27g / L, cellobiose 11g / L, other sugar 8g / L, total sugar 58g / L, add 4M / L NaOH solution to adjust the pH to 6.5 , according to the proportion of the original total sugar in the hydrolyzate of 5w%, 20w%, 50w% and 85w%, corn flour is added, so that the total sugar containing corn flour in the hydrolyzate is about 60g / L, 65g / L, 77g / L, 90g / L L, gelatinized at 100°C for 1 hour, then packed into 250ml Erlenmeyer flasks, each Erlenmeyer flask was filled with 150ml. Sterilize at 121°C for 120 minutes in a sterilizer.

[0040] After sterilization, the culture medium was taken out and cooled to room temperature, and ATCC 51743 and CICC8012 strains were inserted into the culture medium with an inoculum size of 5%, and fermented in an anaerobic incubator at 41° C. for 112 hours.

[0041] After the fermentation is complete...

Embodiment 3

[0046] Example 3: Adding organic additives to co-fermentation in cellobiose, xylose and glucose mixed sugar

[0047] In example 2 hydrolyzate, dropwise add 4M / l KOH aqueous solution and adjust pH to be 6.5, add organic agricultural sideline product mixture by 15w%, 20w%, 25w%, 30w% and 50w% of total sugar content in hydrolyzate, comprise bran , rice bran, bean cake powder and bean cake, etc., mix well, and pack into 250ml triangular bottles, each with 150ml. Sterilize at 121°C for 120 minutes in a sterilizer.

[0048] After sterilization, the culture medium was taken out and cooled to room temperature, and ATCC 51743 and CICC8012 strains were inoculated into the culture medium with an inoculum size of 5%, and fermented in an anaerobic incubator at 42°C for 108 hours.

[0049] After the fermentation is complete, get 1ml of fermented liquid and place it in a centrifuge tube, centrifuge at a speed of 11000 rpm for 7 minutes, and use gas chromatography to measure the contents of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com