Method for preparing nano-branched titanium dioxide photoanode of dye sensitized solar cell

A technology of solar cells and titanium dioxide is applied in the field of photoanode of solar cells, which can solve the problems of reducing the surface area of dye adsorption, difficulty in improving the efficiency, and large diameter of nano-arrays, so as to improve the light absorption efficiency, increase the surface area, and increase the adsorption. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Put the FTO conductive glass (1cmx2cm) into acetone, deionized water, and absolute ethanol for ultrasonic cleaning for 30 minutes, and then dry it for use.

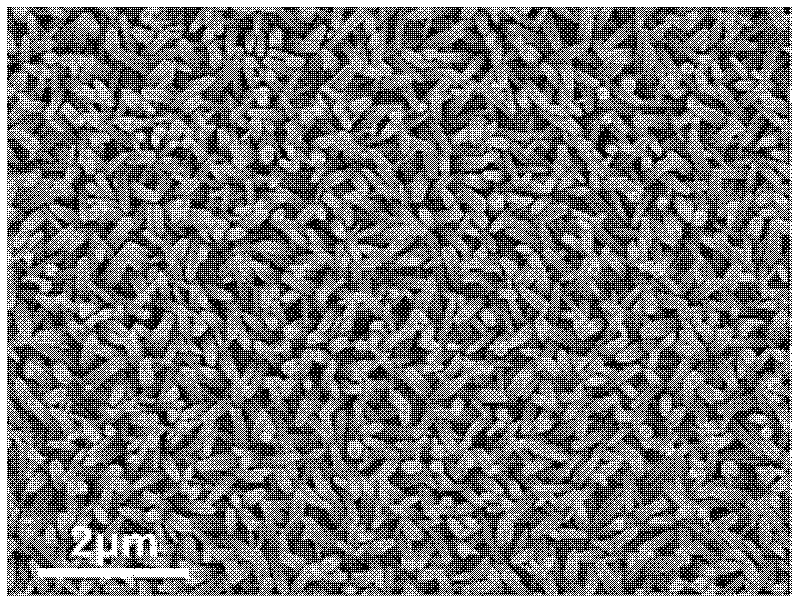

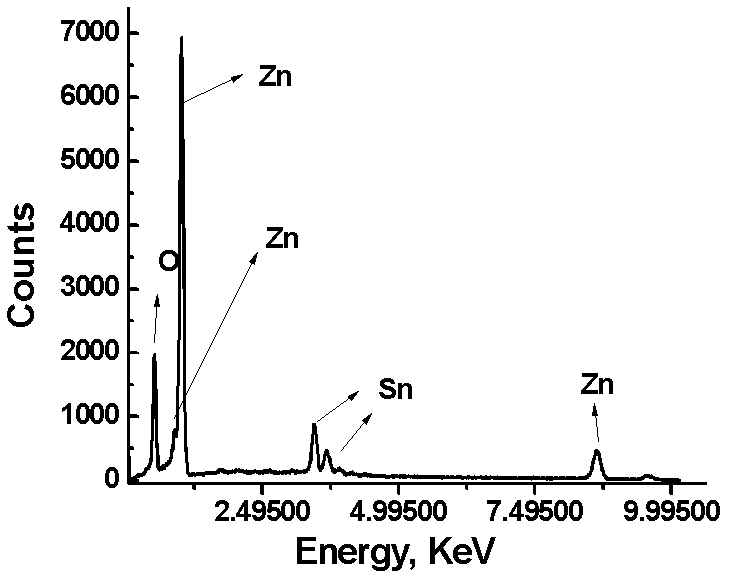

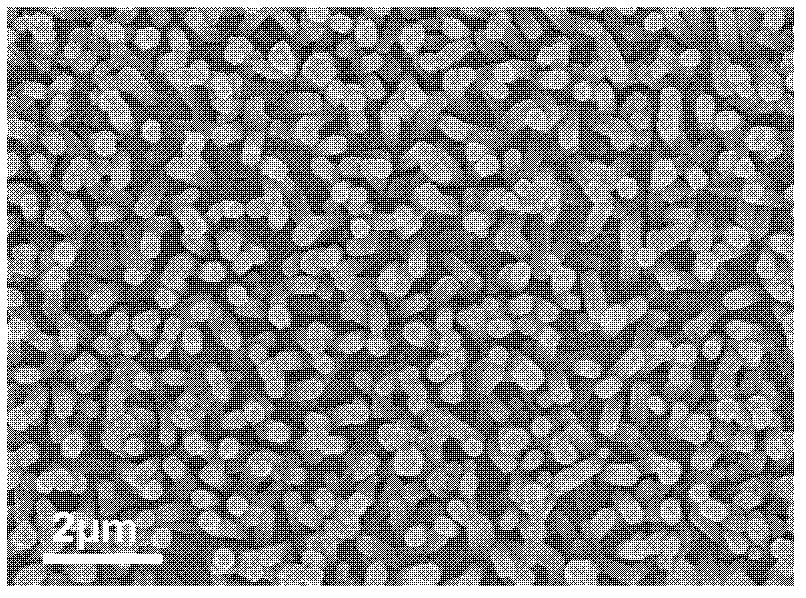

[0038] 2) Deposit a layer of ZnO nanorod array template on the FTO by using constant current method. Electrodeposition uses a two-electrode system: FTO is the working electrode, and the Pt electrode is the counter electrode. Electrolyte consists of 5mM Zn(NO 3 ) 2 and 5mM C 6 h 12 N 4 composition. Deposit for 60 minutes under the condition of constant temperature and constant flow, wash with deionized water and set aside for use. Such as figure 1 with 2 As shown, after 60min of electrodeposition, ZnO nanorod arrays with a length of about 1.5μm±25nm and a diameter of about 150±20nm were grown on FTO, from figure 1 with 2 It can be seen that the ZnO nanorods are regular hexagons, and the prepared nanorods are not very vertically ordered due to the unevenness of the FTO surface.

[0039] 3) Place the ZnO...

Embodiment 2

[0047] Front three steps (step 1), 2), 3)) are identical with embodiment 1.

[0048] 4) Soak the calcined titanium dioxide nanorods in 0.1-0.5M TiCl 4 In the solution for 30-60min, then placed in a 100ml reactor, the FTO conductive glass leans against the inner wall of the reactor. Next, add 50 ml of HCl (10%-27% by mass fraction) solution into the reaction kettle, add tetrabutyl titanate with a volume fraction of 1%-6% into the solution, and stir evenly. Finally, the reactor was subjected to a hydrothermal reaction at 150-180° C. for 2 hours. After 2 hours of hydrothermal treatment, the surface morphology of the photoanode is as follows Image 6 Shown in b: TiO 2 Branched nanowires grow on the surface of the nanorods, by XRD (see Figure 7 The characterization of c) can prove that these branch-like nanowires are TiO in the rutile phase 2 .

[0049] 5) A certain amount of tetrabutyl titanate and HF are mixed, placed in a reaction kettle, and sealed. Put the reaction ket...

Embodiment 3

[0051] Front three steps (step 1), 2), 3)) are identical with embodiment 1.

[0052] 4) Soak the calcined titanium dioxide nanorods in 0.1-0.7M TiCl 4 In the solution for 30-60min, then placed in a 100ml reactor, the FTO conductive glass leans against the inner wall of the reactor. Next, add 50 ml of HCl (10%-27% by mass fraction) solution into the reaction kettle, add tetrabutyl titanate with a volume fraction of 1%-6% into the solution, and stir evenly. Finally, the reactor was subjected to a hydrothermal reaction at 150-180° C. for 2.5 hours. After 2.5 hours of hydrothermal treatment, the surface morphology of the photoanode is as follows Image 6 As shown in c: most of TiO 2 The nanorods have been covered by branched nanowires, and the overall morphology presents a one-dimensional array structure with clusters at the top.

[0053] 5) A certain amount of tetrabutyl titanate and HF are mixed, placed in a reaction kettle, and sealed. Put the reaction kettle into an oven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com