Composite catalyst of self-humidifying fuel cell and manufacturing method and application thereof

A composite catalyst and fuel cell technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve the problems of increasing membrane internal resistance, reducing battery performance, and unsuitability, so as to improve activity and prepare The method is simple and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of composite carrier: Add 2ml of tetraethyl orthosilicate to ethanol to make 100ml of tetraethyl orthosilicate / ethanol solution to obtain a mixed solution;

[0049] (2) Add 1 gram of RuCl 3 ·3H 2 O was added to ethanol to make 20mg / ml RuCl 3 ·3H 2 O / ethanol solution, obtains mixed solution;

[0050] (3) Take 5.9ml of the mixed solution obtained in step (1) and 0.3ml of the mixed solution obtained in step (2) (volume ratio is 19.7:1), then add 500mg of oxidized XC-72R carbon black, at room temperature Stir under low pressure and ultrasonic for half an hour each to mix tetraethyl orthosilicate and metal precursors with carbon black evenly. Evaporate in a water bath at 70°C for 4 hours. After evaporating ethanol, put it in a vacuum oven at 80°C and vacuumize for 6 hours to further remove the residue. ethanol, and then sintered at 300°C for 8 hours under an inert atmosphere, and cooled to obtain a composite carrier. The content of silicon dioxide in the ...

Embodiment 2

[0058] The preparation of the composite carrier is similar to the preparation of 6.5wt%RuSiOx / C in Example 1, the difference is: take 6ml of the mixed solution obtained in step (1) in Example 1, and take 1.2 ml of the mixed solution obtained in step (2) in Example 1 ml, take 500mg of oxidized carbon nanotubes, the calcination temperature is 400°C, the calcination time is 5h, the silicon oxide content in the carrier is 6wt%, the ruthenium oxide content is 2wt%, which can be expressed as 8wt%RuSiOx / C, ruthenium oxide The mass ratio to silicon oxide is 1:3; the catalyst preparation steps, membrane electrode preparation steps, methanol electrocatalytic performance evaluation steps, oxygen reduction performance evaluation steps and membrane electrode testing steps are all the same as in Example 1.

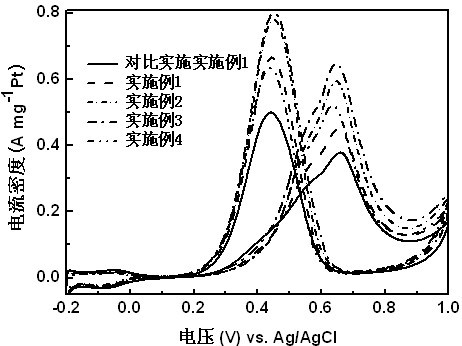

[0059]After testing: the methanol anodic oxidation current (forward scanning peak current) density of the catalyst prepared in this embodiment is 0.59A / mgPt, and the oxygen reduction cur...

Embodiment 3

[0061] The preparation of the composite carrier is similar to the preparation of 6.5wt%RuSiOx / C in Example 1, the difference is: take 6.1ml of the mixed solution obtained in step (1) in Example 1, and take the mixed solution obtained in step (2) in Example 1 1.7ml, the calcination temperature is 500°C, the silicon oxide content in the carrier is 6wt%, the ruthenium oxide content is 3wt%, which can be expressed as 9wt%RuSiOx / C, the mass ratio of ruthenium oxide and silicon oxide is 1:2; The preparation steps, membrane electrode preparation steps, methanol electrocatalytic performance evaluation steps, oxygen reduction performance evaluation steps and membrane electrode testing steps are all the same as in Example 1.

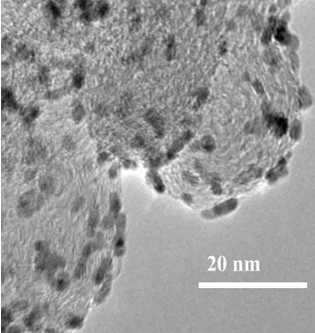

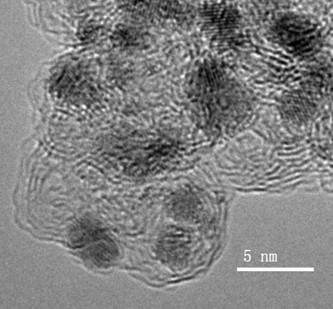

[0062] Figure 1(a) And Fig. 1(b) is the structure characterization diagram of the composite catalyst using JEOL JEM2100 electron microscope. It can be seen from the figure that the composite catalyst is evenly distributed and the particle size is about 2.5nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com