Comprehensive treatment method for wastewater of coal coking device

A coal coking and wastewater technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of non-recycling, complicated treatment process, investment, operating costs, high land occupation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

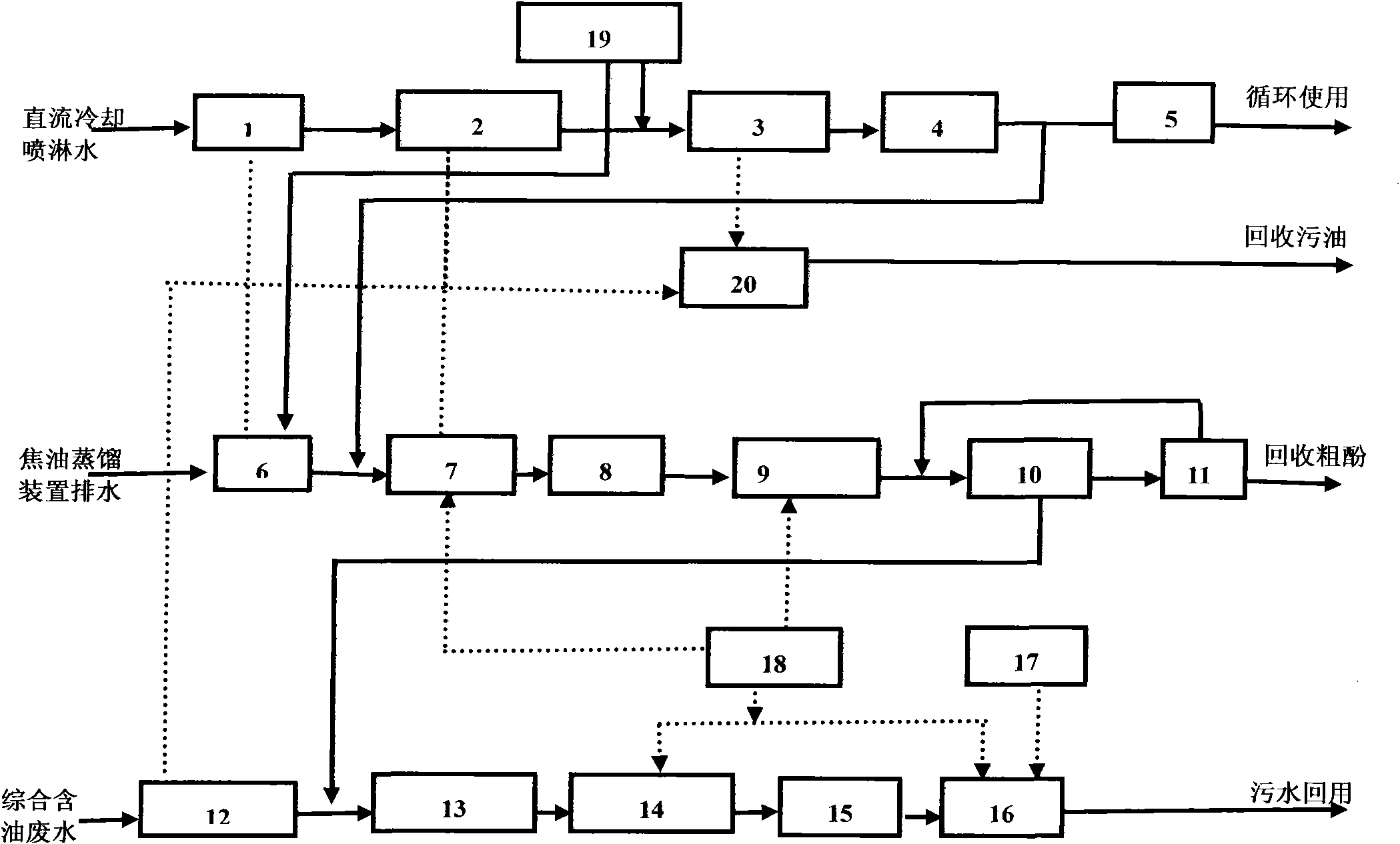

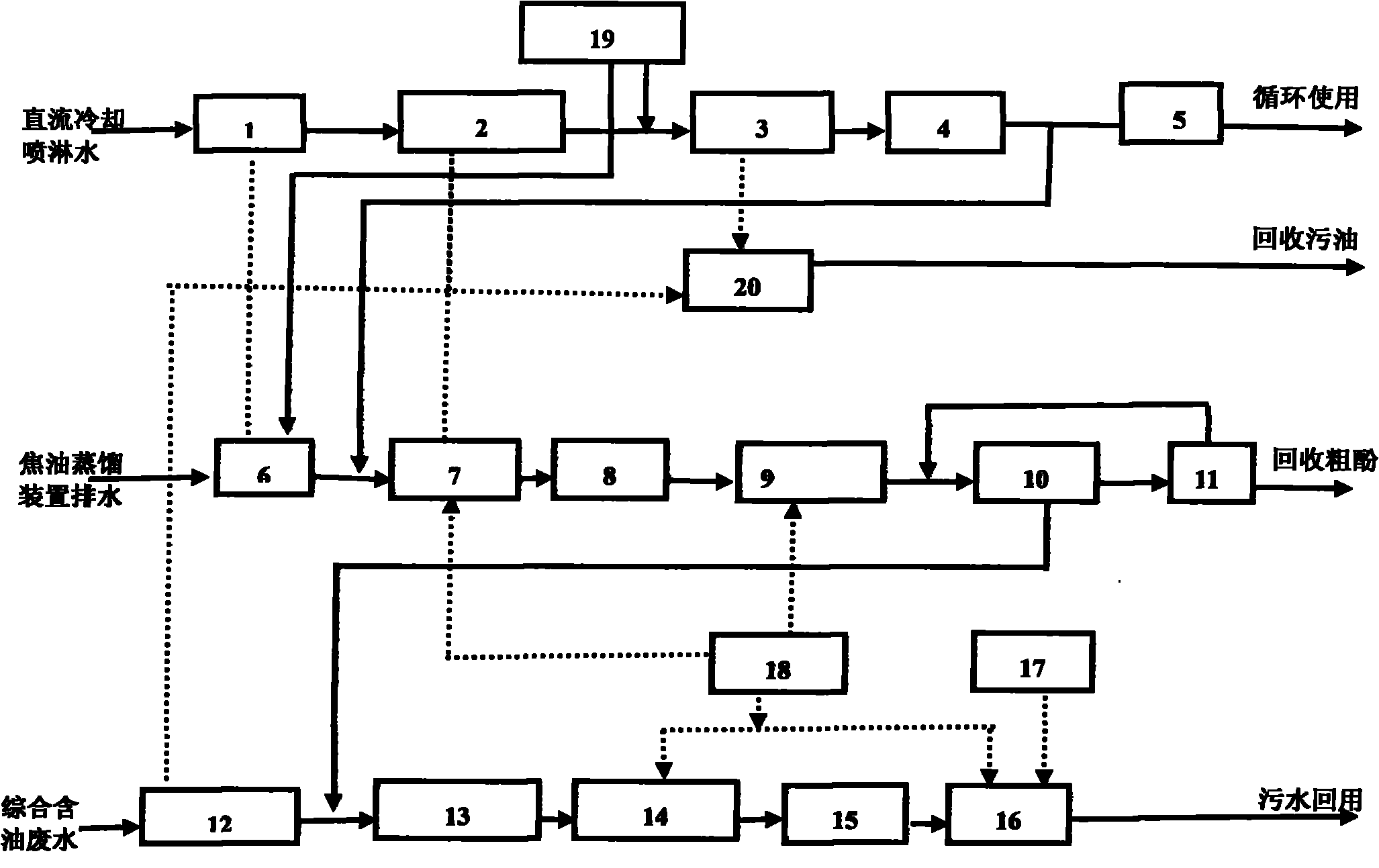

[0033] The treatment method of the present invention is used to classify and classify the waste water discharged from the coal coking production plant of a coal chemical enterprise of a coal mine group in China, the condensed cooling and separated waste water after the coal tar distillation treatment, and the refined waste water of products such as gas and tar. quality reuse. Among them, the pollution composition of DC cooling spray wastewater is petroleum 400mg / L, suspended matter 4000mg / L, volatile phenol 3000mg / L, and temperature 56°C; the pollution composition of tar distillation condensation cooling sewage is petroleum 9000mg / L, COD 12000mg / L, ammonia nitrogen 370mg / L, volatile phenol 3040mg / L, sulfide 0.5mg / L, pH 7.8, temperature 60°C; gas and tar and other products refined mixed drainage petroleum 300mg / L, COD 1500mg / L, ammonia nitrogen 100mg / L L. Volatile phenol 100mg / L, sulfide 50mg / L, pH 7-8, temperature 35°C. The method of the invention is adopted for classificati...

Embodiment 2

[0038] Adopt the treatment method of embodiment 1, process the direct-flow spray cooling waste water 2000m identical with embodiment 1 3 / h. The main components and process parameters of the treatment device are: (1) two groups of inclined plate sedimentation tanks, which adopt a closed structure, and the overall combined size is 20×15×8m; the effective residence time is 15min, and the surface load is 3.0m 3 / m 2 h; the pool body adopts steel concrete structure, lined with glass fiber reinforced plastic for anticorrosion; the sloping plate is made of hard plastic plate; equipped with 2 sets of screw mud conveyors. (2) 4 hydrocyclones, the size of each unit is 1.02×0.955×2.755m; the design pressure is 0.04MPa; the material is made of wear-resistant composite materials. (3) 7 sets of coalescing filters, single size 6.6×2.2×2.2m; filtration rate 40m / h, pressure 0.1~0.2MPa; main material adopts carbon steel structure; filler adopts hydrophilic and oleophobic fiber filter materia...

Embodiment 3

[0041] Adopt the processing method of embodiment 1, process the same tar distillation waste water 4.0m as embodiment 1 3 / h and 24m from Example 2 3 / h system sewage. The main components and process parameters of the treatment device are: (1) One high-efficiency oil-water separator, with a diameter of 1.2m and a height of 2.15m; the operating pressure is 0.1-0.2MPa; the main material is made of carbon steel; the filler is made of coarse-grained polymer filter materials; set up an online automatic backwashing system. (2) One dissolved air flotation machine, 4.35×2×2.2m; dissolved air pressure 0.3MPa, reflux ratio 50%; main material adopts steel concrete integrated structure, lined with glass fiber reinforced plastic for anticorrosion; supporting auxiliary equipment includes dissolved air tank 1 set, 1 set of dissolved air water pump, 1 set of mud scraper, 3 sets of TVIII air releaser. (3) One intermediate pool, with a size of 3.5×3.5×4m; the effective residence time is 30 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com