Aqueous polypyrrole/attapulgite electrically-conducting paint and its preparation method

A technology of attapulgite and conductive coatings, applied in conductive coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor conductive effect, unstable conductive performance, easy precipitation, etc., and achieve high thermal and chemical stability , Improve the integrity of the coating, and the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

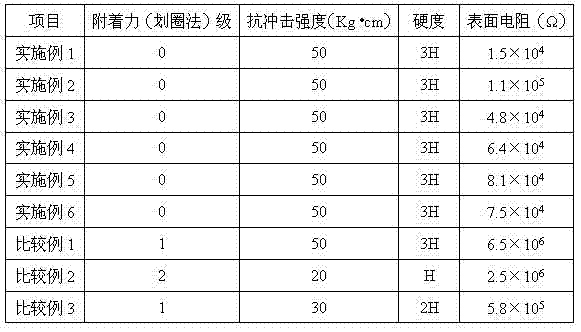

Examples

Embodiment 1

[0031] (1) Add 12 grams of γ-aminopropyltriethoxysilane to 1 liter of attapulgite composite material slurry with a mass concentration of 60 g / liter, heat up to 80°C, heat and stir for 8 hours, and cool to 10°C , add 24.35 grams of sodium dodecylsulfonate (0.089mol) and 18 grams of pyrrole monomer (0.27mol) in turn, continue to stir, add 61.38 grams of ammonium persulfate (0.27mol), keep warm for 4 hours, filter with suction and wash Until the filtrate is neutral, polypyrrole / attapulgite composite filter cake is obtained, and the solid content of the filter cake is 25% (mass percentage, the same below);

[0032] (2) Add 105 grams of deionized water and 0.45 grams of BKY-161 to 60 grams of the polypyrrole / attapulgite composite material filter cake prepared in step (1), and ultrasonically disperse for 25 minutes to obtain the polypyrrole / attapulgite composite material slurry;

[0033](3) To 80 grams of water-based hydroxyacrylic acid emulsion (produced by China Textile A...

Embodiment 2

[0036] (1) Add 4 g of γ-aminopropyltrimethoxysilane to 1 L of attapulgite slurry with a mass concentration of 10 g / L, heat up to 60°C, keep stirring for 2 hours, cool to 0°C, and add 0.73 1 gram of sodium dodecylbenzenesulfonate (0.0021mol), 1 gram of pyrrole monomer (0.015mol), continue to stir, add 1.71 grams of ammonium persulfate (0.0075mol), keep warm for 1 hour, filter with suction, and wash until the filtrate is Neutral, that is, polypyrrole / attapulgite composite filter cake is obtained, and the solid content of the filter cake is 25%;

[0037] (2) Take 60 grams of polypyrrole / attapulgite composite filter cake prepared in step (1), add 255 grams of deionized water, 0.15 grams of BKY-163, and ultrasonically disperse for 30 minutes to obtain polypyrrole / attapulgite composite material slurry;

[0038] (3) Add the conductive paste containing 8 grams of polypyrrole / attapulgite composite material, 5 grams of deionized water, 0.5 grams of 201 methyl silicone oil, ...

Embodiment 3

[0041] (1) Add 0.5 g of N-β(aminoethyl)-γ-aminopropyltrimethoxysilane to 1L of attapulgite slurry with a mass concentration of 10 g / L, heat up to 90°C, and keep stirring for 20 hours . Cool to 30°C, add 9.14 g of sodium benzenesulfonate (0.051 mol) and 5 g of pyrrole monomer (0.075 mol) in sequence, continue stirring, add 8.55 g of ammonium persulfate (0.0375 mol), keep warm for 6 hours, and filter with suction. Washing until the filtrate is neutral, the polypyrrole / attapulgite composite material filter cake is obtained, and the solid content of the filter cake is measured to be 25%;

[0042] (2) Take 60 grams of polypyrrole / attapulgite composite filter cake prepared in step (1), add 30 grams of deionized water, 0.6 gram of BKY-164, and ultrasonically disperse for 30 minutes to obtain polypyrrole / attapulgite composite material slurry;

[0043] (3) Add the conductive paste containing 30 grams of polypyrrole / attapulgite composite material, 20 grams of deionized water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com