Metal-coated polyimide resin substrate with excellent thermal aging resistance properties

A technology for coating polyimide resin and polyimide resin, which is applied in liquid chemical plating, superimposed layer plating, metal layered products, etc., can solve problems such as differences in peel strength test results, and achieve excellent effect, the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

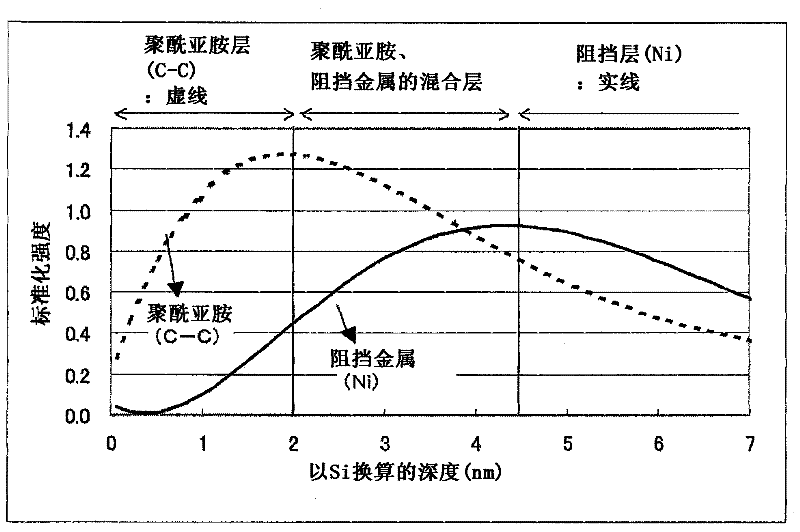

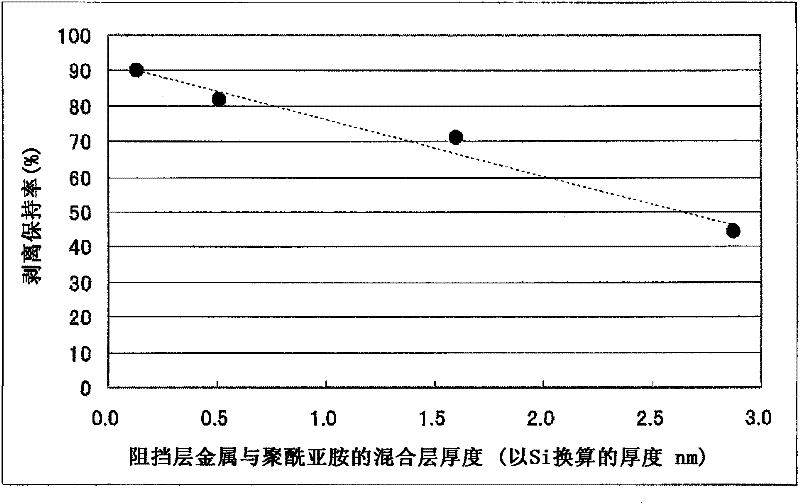

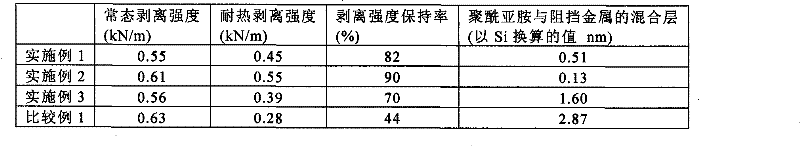

[0047]Capton 150EN of DuPont was used as the polyimide resin film. As a surface modification method, this polyimide resin film was immersed in an aqueous potassium hydroxide solution, and washed with pure water. Then, as a catalyst application process, it is dipped in a solution obtained by mixing or reacting a silane coupling agent having a functional group having a metal-capturing ability and a noble metal compound in advance, and washed with pure water.

[0048] After this treatment, as an electroless plating process, a nickel layer of 0.15 μm is formed using an electroless nickel-boron-based plating solution, washed with pure water, and then heat-treated at 150°C to form a nickel layer of 0.05 μm and then washed with pure water. A nickel layer of 0.20 μm was formed in total. Next, an electroless copper seed layer was formed on the nickel layer in an electroless copper plating solution, and then an 8 μm copper conductor layer was formed by electroplating.

[0049] The thu...

Embodiment 2

[0056] Capton 150EN of DuPont was used as the polyimide resin film. As a surface modification method, after irradiating this polyimide resin film with UV, it immersed in sulfuric acid, and washed with pure water after that. Then, as a catalyst application process, it is dipped in a solution obtained by mixing or reacting a silane coupling agent having a functional group having a metal-capturing ability and a noble metal compound in advance, and washed with pure water.

[0057] After this treatment, as an electroless plating step, a nickel layer of 0.2 μm was formed using an electroless nickel-boron-based plating solution, followed by washing with pure water. Next, an electroless copper seed layer was formed on the nickel layer in an electroless copper plating solution, and then an 8 μm copper conductor layer was formed by electroplating.

[0058] The thus-formed metal-clad polyimide resin substrate was measured for 90° peel strength, and the polyimide thickness of the peeled ...

Embodiment 3

[0063] Capton 150EN of DuPont was used as the polyimide resin film. As a surface modification method, after irradiating this polyimide resin film with UV, it was dipped in nitric acid and washed with pure water. Then, as a catalyst application process, it is dipped in a solution obtained by mixing or reacting a silane coupling agent having a functional group having a metal-capturing ability and a noble metal compound in advance, and washed with pure water.

[0064] After this treatment, as an electroless plating process, a nickel layer of 0.15 μm is formed using an electroless nickel-boron-based plating solution, washed with pure water, and then heat-treated at 150°C to form a nickel layer of 0.05 μm and then washed with pure water. A nickel layer of 0.20 μm was formed in total. Next, an electroless copper seed layer was formed on the nickel layer in an electroless copper plating solution, and then an 8 μm copper conductor layer was formed by electroplating.

[0065] The thu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com