Metal particle doped indium salt-based phosphor and preparation method thereof

A technology of indium salt and phosphor powder, applied in the field of phosphor powder, can solve the problems of reducing the luminous efficiency of phosphor powder, low voltage luminous efficiency, easy to decompose and emit gas, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of an indium salt-based phosphor doped with metal particles, such as Figure 4 shown, including the following steps:

[0030] S1, according to the general chemical formula Re' 1-x Re″InO 3 : the stoichiometric ratio of each element in yM, taking by weighing the nanoparticles of M, the source compound of Re', the source compound of Re" and the source compound of indium; wherein, Re' is one or two of Y, La, Sc; Re" is one or two of Tm, Tb, Eu, Sm, Gd, Dy, Ce; M is one or two of Ag, Au, Pt, Pd; x is 0.001-0.2, y is 5 ×10 -5 ~1×10 -2 ;

[0031] S2. Dissolving the weighed source compound of Re′, Re″ and In in aqueous alcohol solution to obtain a mixed solution;

[0032] S3. Adding the M nanoparticles to an aqueous solution containing a surface treatment agent to obtain surface-treated M nanoparticles;

[0033] S4. Add the surface-treated M nanoparticles into the mixed solution in step S2, stir, then add citric acid monohydrate and polyethylene glyc...

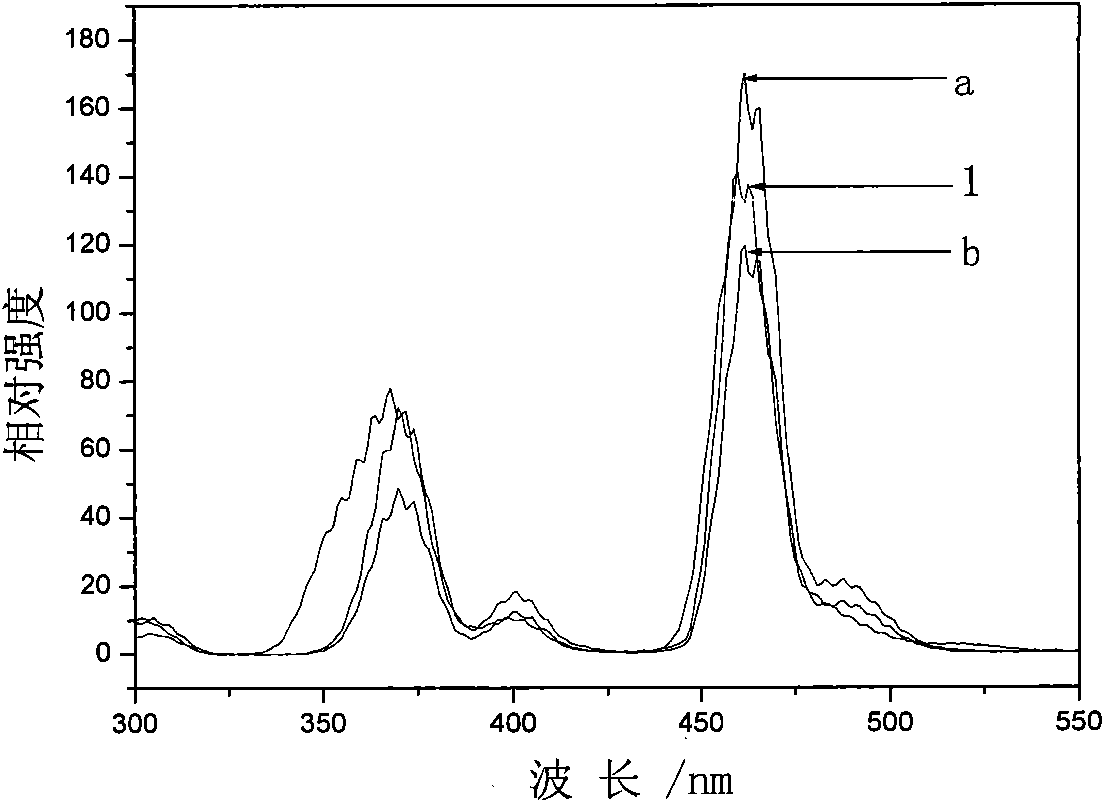

Embodiment 1

[0044] Preparation of Y by sol-gel method 0.999 T m 0.001 InO 3 :5×10 -4 Pt

[0045] Weigh 5.2mg of chloroplatinic acid and dissolve it in 17mL of ethanol. After it is completely dissolved, add 8mg of sodium citrate and 1.2mg of sodium dodecylsulfonate while stirring, and then slowly drop in 0.4mg of sodium borohydride solution. to 10 mL of ethanol to obtain 1 x 10 -3 mol / L sodium borohydride alcohol solution 0.4mL, after reacting for 5min, add 1×10 -2 mol / L hydrazine hydrate solution 2.6mL, after 40min of reaction, 30ml of Pt content is 5×10 -4 mol / L Pt nanoparticle sol. Weighing 0.15g of PVP was added to the Pt nanoparticle sol, and magnetically stirred for 12 hours to obtain surface-treated Pt nanoparticles.

[0046] 0.01molY 0.999 T m 0.001 InO 3 :5×10 -4 Preparation of Pt: measure 10ml 1mol / L Y(NO 3 ) 3 , 1ml 0.01mol / L Tm(NO 3 ) 3 and 10ml 1mol / L In(NO 3 ) 3 Put the solution in a beaker, add 9ml of water and 30ml of ethanol mixed solution and 10ml of the ...

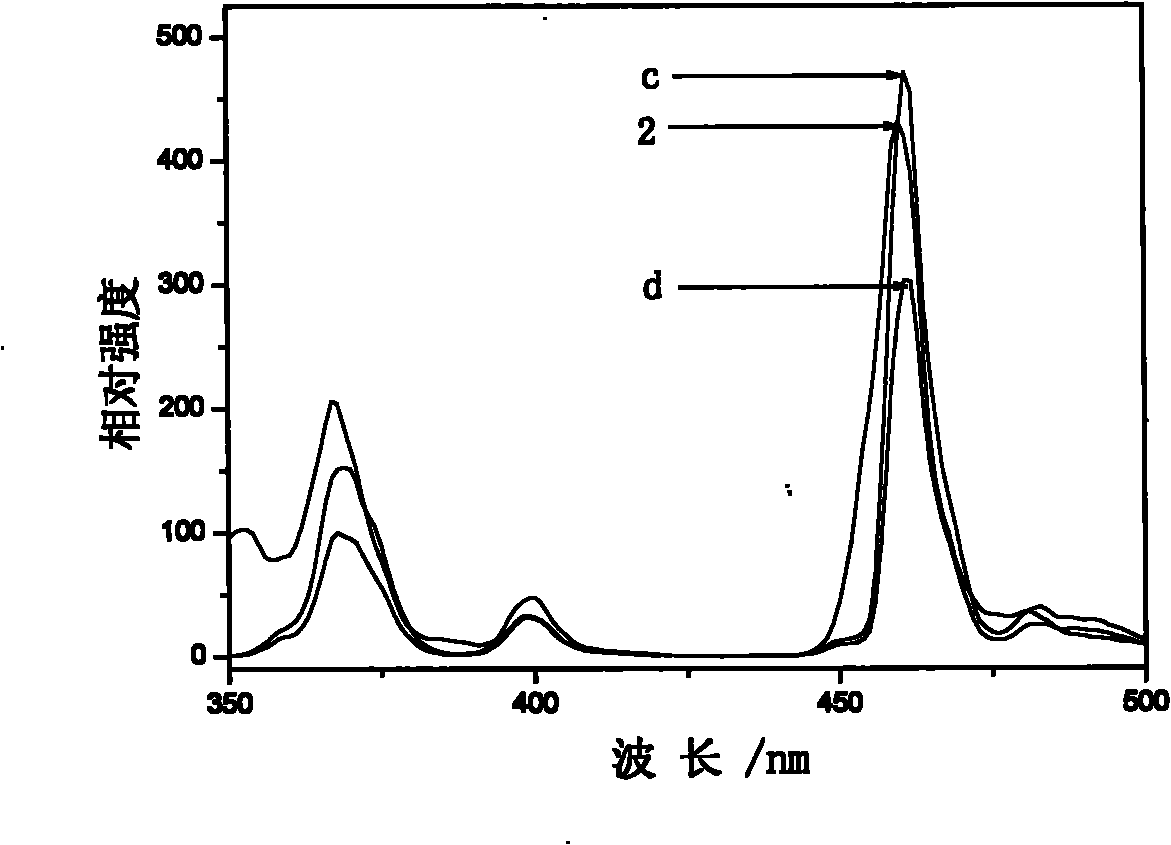

Embodiment 2

[0048] Preparation of La by sol-gel method 0.995 SM 0.005 InO 3 :1×10 -3 Au

[0049] Weigh 7.6 mg of sodium borohydride and dissolve it in 10 mL of ethanol to obtain 10 mL of sodium borohydride alcohol solution with a concentration of 0.02 mol / L for future use. Weigh 16.4mg of chloroauric acid and dissolve it in 7.5mL of ethanol. After it is completely dissolved, add 56mg of sodium citrate and 24mg of cetyltrimethylammonium bromide under stirring, and add to the mixed solution under magnetic stirring. Add 2.5mL of the above-prepared sodium borohydride alcohol solution to the mixture, and continue the reaction for 30min to obtain 10ml of Au content of 4×10 -3 mol / L Au nanoparticle sol. Weighing 1 g of PVP was added to the Au nanoparticle sol, and magnetically stirred for 8 hours to obtain surface-treated Au nanoparticles.

[0050] 0.01mlLa 0.995 SM 0.005 InO 3 :1×10 -3 Preparation of Au: measure 9.95ml 1mol / L LaCl 3 , 1ml0.05mol / L Sm(NO 3 ) 3 and 10ml 1mol / L In(NO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com