Method for synthesizing floriform cobalt magnetic powder by mixed solvent thermal method

A magnetic powder and solvent technology, which is applied in the field of solvothermal synthesis of flower-shaped cobalt magnetic powder, can solve the problems of numerous auxiliary raw materials, unfavorable industrial production, and complicated cobalt powder process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Disperse 1.25g of cobalt acetate into 15ml of ethylene glycol solution, then disperse 4g of sodium hydroxide into 15ml of deionized water to obtain sodium hydroxide solution (6.66M), then pour the two solutions into polytetrafluoroethylene, they After complete mixing an additional 5 ml of hydrazine hydrate was added. The ratio of deionized water, ethylene glycol and hydrazine hydrate is 3:3:1, the filling volume is 4 / 5, the bushing is installed, and the temperature is kept at 180°C for 36 hours. Finally, naturally cool to room temperature, collect the mother liquor, wash the precipitate repeatedly, separate, collect and dry the cobalt magnetic powder with a permanent magnet.

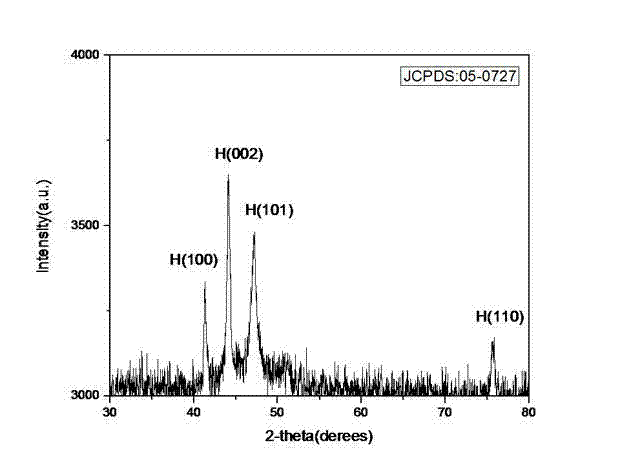

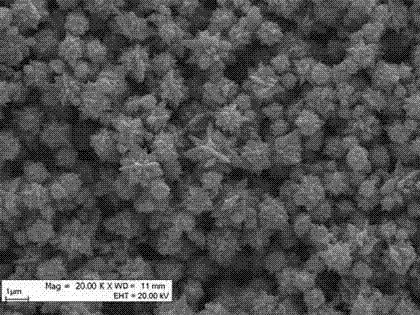

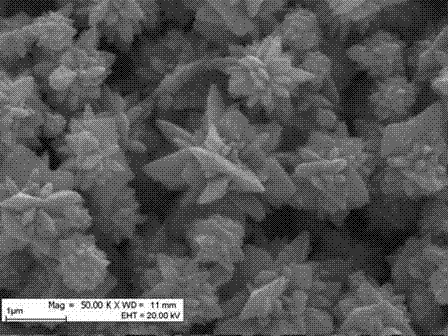

[0017] XRD analysis results show that the product is cobalt with hexagonal packing (hcp) structure, such as figure 1 ; Scanning electron microscopy (SEM) analysis results show that the product is a monodisperse uniform flower-like morphology, such as figure 2 . image 3 It is a high-magnifica...

Embodiment 2

[0019] Disperse 1.25g of cobalt acetate into 15ml of ethylene glycol solution, then disperse 4g of sodium hydroxide into 15ml of deionized water to obtain sodium hydroxide solution (6.66M), then pour the two solutions into polytetrafluoroethylene, they After complete mixing an additional 5 ml of hydrazine hydrate was added. The ratio of deionized water, ethylene glycol and hydrazine hydrate is 3:3:1, the filling volume is 4 / 5, the bushing is installed, and the temperature is kept at 180°C for 4 hours. Finally, naturally cool to room temperature, collect the mother liquor, wash the precipitate repeatedly, separate, collect and dry the cobalt magnetic powder with a permanent magnet. The results of scanning electron microscope (SEM) analysis show that the product is monodisperse irregular particles with a diameter of 0.3-0.5 μm, such as Figure 4 .

Embodiment 3

[0021] Disperse 1.25g of cobalt acetate into 15ml of ethylene glycol solution, then disperse 4g of sodium hydroxide into 15ml of deionized water to obtain sodium hydroxide solution (6.66M), then pour the two solutions into polytetrafluoroethylene, they After complete mixing an additional 5 ml of hydrazine hydrate was added. The ratio of deionized water, ethylene glycol and hydrazine hydrate is 3:3:1, the filling volume is 4 / 5, the bushing is installed, and the temperature is kept at 180°C for 12 hours. Finally, naturally cool to room temperature, collect the mother liquor, wash the precipitate repeatedly, separate, collect and dry the cobalt magnetic powder with a permanent magnet.

[0022] The results of scanning electron microscopy (SEM) analysis showed that the product was monodisperse with a diameter of 0.6-0.9 μm and just started to form a flower-like morphology, such as Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com