Sodium tantalate film ultraviolet light detector and preparation method thereof

An ultraviolet light and detector technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as excessive particle size of materials, and achieve the effect of low defect density, simple process and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

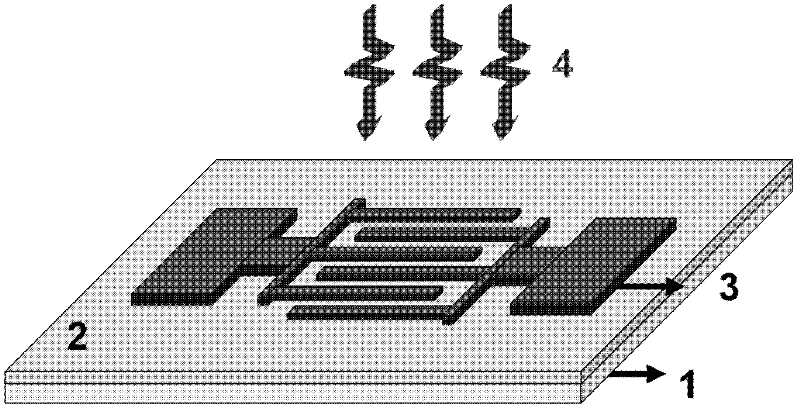

[0024] First, a layer of NaTaO with a thickness of 0.5 μm was grown on a clean metal substrate by hydrothermal synthesis. 3 film.

[0025] Dissolve 2 grams of sodium hydroxide in 14 milliliters of deionized water, then place the sodium hydroxide solution in the reaction kettle, put the tantalum sheet (16mm×12mm×1mm) in the reaction kettle and seal the reaction kettle, then put the reaction The kettle was placed in a resistance furnace, and the temperature was adjusted to 150°C and heated for 9 hours; the reactor was taken out and cooled to room temperature, and then the tantalum sheet was taken out, rinsed with deionized water, and then dried with nitrogen.

[0026] In the prepared NaTaO 3 The thin film is covered with a mask plate complementary to the interdigitated electrode structure. Use magnetron sputtering technology to sputter a layer of metal on the finger pattern: put the sample in a vacuum chamber and evacuate to 3.0×10 -3 Pa; then pass Ar gas, the sputtering pres...

Embodiment 2

[0029] A layer of NaTaO with a thickness of 1 μm was grown on a metal substrate by hydrothermal synthesis 3 film.

[0030] Dissolve 2.6 grams of sodium hydroxide in 14 milliliters of deionized water, then place the sodium hydroxide solution in the reaction kettle, put the tantalum sheet (16mm×12mm×1mm) into the reaction kettle and seal the reaction kettle, then put the reaction The kettle was placed in a resistance furnace, and the temperature was adjusted to 150°C and heated for 12 hours; the reactor was taken out and cooled to room temperature, and then the tantalum sheet was taken out, rinsed with deionized water, and then dried with nitrogen.

[0031] In the prepared NaTaO 3 The thin film is covered with a mask plate complementary to the interdigitated electrode structure. Use magnetron sputtering technology to sputter a layer of metal on the finger pattern: put the sample in a vacuum chamber and evacuate to 3.0×10 -3 Pa; then pass Ar gas, the sputtering pressure is 0.8...

Embodiment 3

[0034] A layer of NaTaO with a thickness of 2 μm was grown on a metal substrate by hydrothermal synthesis 3 film.

[0035]Dissolve 3 grams of sodium hydroxide in 14 ml of deionized water, then place the sodium hydroxide solution in the reaction kettle, put the tantalum sheet (16mm×12mm×1mm) in the reaction kettle and seal the reaction kettle, then put the reaction The kettle was placed in a resistance furnace, and the temperature was adjusted to 180°C and heated for 12 hours; the reactor was taken out and cooled to room temperature, and then the tantalum sheet was taken out, rinsed with deionized water, and then dried with nitrogen.

[0036] In the prepared NaTaO 3 The thin film is covered with a mask plate complementary to the interdigitated electrode structure. Use magnetron sputtering technology to sputter a layer of metal on the finger pattern: put the sample in a vacuum chamber and evacuate to 3.0×10 -3 Pa; then pass Ar gas, the sputtering pressure is 0.8Pa, the sputte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com