Floating microorganism adhesive porous hydrogel and preparation method thereof

A technology of porous hydrogel and floating organisms, applied in the direction of drug combination, pharmaceutical formula, medical preparations containing active ingredients, etc., can solve the problems of low mechanical properties of hydrogel, time-consuming, low crystallinity, etc., to achieve improved Effects of bioavailability, prolonged residence time, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Implementation example one Nimodipine pectin calcium porous hydrogel

[0028] Add 0.5 g nimodipine to 20 mL 5 g / L surfactant aqueous solution to form a suspension, stir, add 1 g pectin to dissolve to form a uniform and viscous mixture, add the above mixture to 100 mL 50 g / L of calcium chloride solution, add all the solution and continue to stir for 15 minutes, filter, wash with 100 mL of water, and dry to obtain nimodipine calcium pectin porous hydrogel.

Embodiment 2

[0029] Implementation example two nimodipine pectin calcium-chitosan porous hydrogel

[0030] Add 0.6 g of nimodipine to 20 mL of 5 g / L surfactant aqueous solution to form a suspension, stir, add 1 g of pectin to dissolve to form a uniform and viscous mixture, and add the above mixture to 100 mL of 20 g / L calcium chloride solution (containing chitosan with a concentration of 2 g / L), add all of it and continue to stir for 20 minutes, filter, wash with 100 mL of water, and dry to obtain nimodipine pectin calcium-chitosan Sugar porous hydrogel.

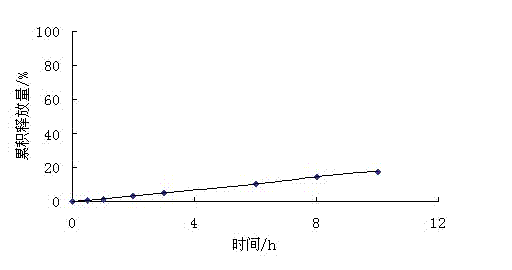

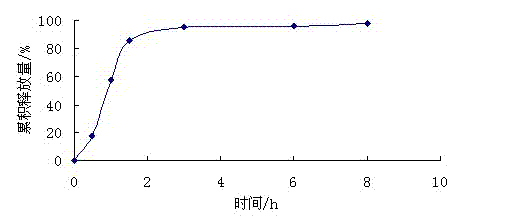

[0031] Refer to the two appendices of the Pharmacopoeia of the People's Republic of China (2005 Edition) C The second method of dissolution test device, the paddle method is used for the release test, the dissolution medium is 900 mL of 0.1 mol / L hydrochloric acid solution, the temperature is (37±0.5) ℃, the rotation speed is 50 r / min, and 100 mg of porous Add the hydrogel into the dissolution vessel, sample 5 mL at regular intervals,...

Embodiment 3

[0033] Implementation example three Ketoprofen sodium alginate-chitosan porous hydrogel

[0034] Add 0.8 g ketoprofen to 40 mL of 5 g / L surfactant aqueous solution to form a suspension, stir, add 0.8 g sodium alginate to dissolve and form a uniform viscous mixture, add the above mixture to 100 mL of 30 g / L calcium chloride solution (containing chitosan with a concentration of 2 g / L), add all of it and continue to stir for 30 minutes, filter, wash with 100 mL of water, and dry to obtain ketoprofen calcium alginate- Chitosan porous hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com