Polypropylene anti-reflection nucleating agent and preparation method thereof

A technology of nucleating agent and polypropylene, which is applied in the field of polypropylene anti-reflection nucleating agent and its preparation, can solve the problems of limited resin compatibility, infusible products, poor dispersion, etc., and achieve high compatibility and dispersion Good properties, transparency and crystallization temperature increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a preparation method for preparing the polypropylene antireflection nucleating agent by using the above components, the preparation steps are:

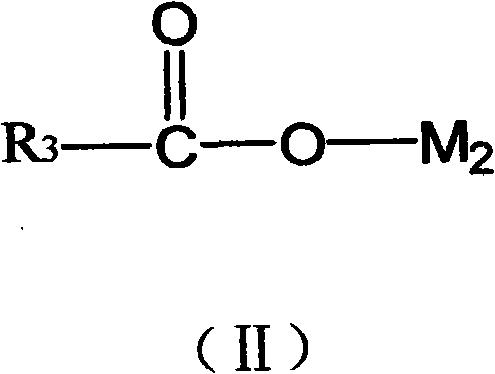

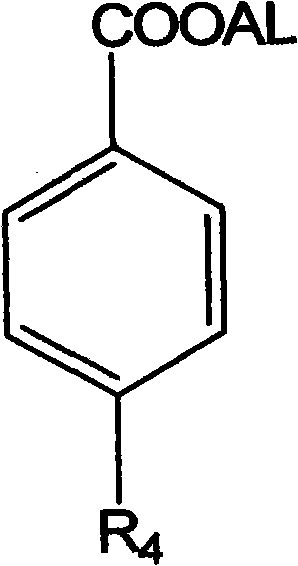

[0051]Take one or two of the A-type compounds, one of the B-type compounds, and the C-type compounds according to the following weight percentages: the weight percentage of the A-type compound is 10-80 parts by weight, and the weight percentage of the B-type compound The percentage is 10 to 50 parts by mass, and the percentage by weight of the C compound is 5 to 70 parts by mass;

[0052] Mix and grind the above-mentioned various compounds in a ball mill for 1 hour,

[0053] A homogeneous nucleating agent powder is obtained.

[0054] The substantive difference between the present invention and the prior art is that the polypropylene anti-reflection nucleating agent of the present invention is formed due to the composition containing the above three crystallization nucleating agents, wherein,...

preparation example 1

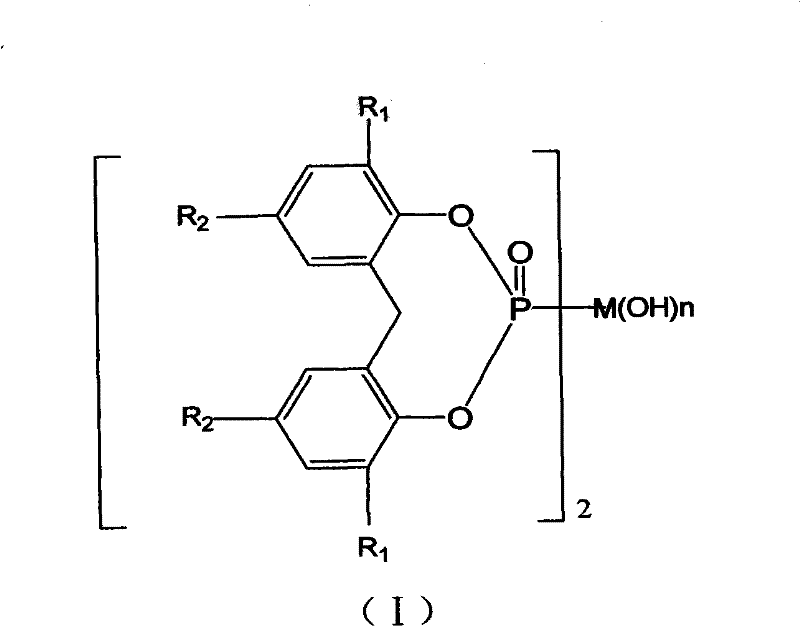

[0057] Preparation example 1 prepares class A compound

[0058] Add 2,2'-methylene-bis(4,6-di-tert-butylphenol) 42.4g, 160ml of toluene and 50ml of triethylamine in the reaction flask, stir until the solid is fully dissolved, and nitrogen gas is passed into the solution, The flow rate is 80ml / min, and at room temperature, add 20ml of phosphorus oxychloride at a uniform rate within 0.5 hours, and react for 12 hours after the addition is complete;

[0059] Add 150ml of water to the reaction bottle, stir for 0.5 hours at 75°C, then distill off the solvent toluene at 85°C, filter the remaining solid-liquid mixture, and wash with water to obtain a solid product, which is the intermediate product 2,2' - methylene-bis(4,6-di-tert-butylphenoxy)phosphate;

[0060] The intermediate product 2,2'-methylene-bis(4,6-di-tert-butylphenoxy)phosphate is dissolved in a mixture of salt-forming solvent acetone and water, and an aqueous aluminum chloride solution is added to the Substitute a diar...

preparation example 2

[0061] Preparation example 2 prepares class A compound

[0062] Add 42.4g of 2,2'-methylene-bis(4-methyl-6-tert-butylphenol), 160ml of toluene and 50ml of triethylamine into the reaction flask, stir until the solid is fully dissolved, and blow nitrogen into the solution In the process, the flow rate is 80ml / min, and at room temperature, 20ml of phosphorus oxychloride is added at a uniform rate within 0.5 hours, and the reaction is carried out for 12 hours after the dropwise addition is completed. Add 150ml of water to the reaction bottle, stir at 75°C for 0.5 hours, then distill off the solvent, filter, and wash with water to obtain a solid product, which is the intermediate product 2,2'-methylene-bis(4-methyl-6- tert-butylphenoxy) phosphate;

[0063] The intermediate product 2,2'-methylene-bis(4-methyl-6-tert-butylphenoxy)phosphate is dissolved in the mixed solution of salt-forming solvent acetone and water, and the aluminum chloride aqueous solution is added to the Said 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com